1. Introduction to Aluminum Panel Curtain Walls

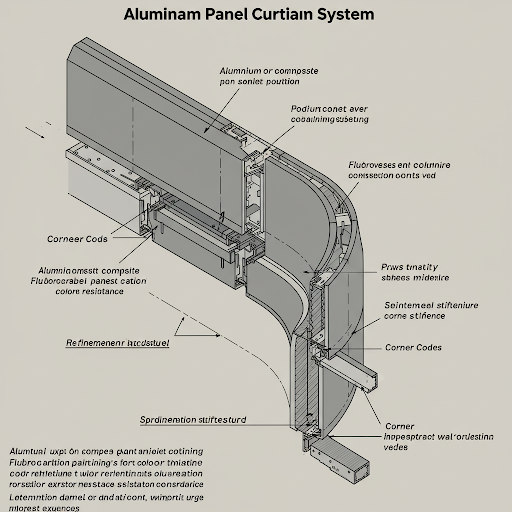

An aluminum panel curtain wall is a versatile exterior cladding system combining aluminum alloy frames with diverse infill materials such as aluminum plates, glass, or composite panels. This engineered facade not only protects buildings but also enhances their aesthetic appeal. Key components include:

- Panels: Typically 1.5mm+ thick aluminum or composite panels (e.g., 0.5mm aluminum layers sandwiching a 3-4mm polyethylene core).

- Coatings: Fluorocarbon paint ensures 25-year color retention and corrosion resistance.

- Structure: Stiffeners and corner codes reinforce panels, enabling complex shapes like arcs or spheres.

2. Evolution and Market Dynamics

2.1 Historical Development

- 1970s-1990s: China’s aluminum curtain wall industry emerged, transitioning from glass to metal panels due to their design flexibility.

- 2000s-Present: Advances in composite materials and coatings (e.g., PVDF) expanded applications, with aluminum now dominating global markets.

2.2 Growth Drivers

- Urbanization: Rapid city development fuels demand for modern, durable facades.

- Green Policies: Standards like GB/T 34327-2017 promote eco-friendly, recyclable materials.

- Innovation: Automated production lines and smart coatings enhance efficiency and performance.

3. Advantages of Aluminum Panel Curtain Walls

3.1 Unmatched Durability and Corrosion Resistance

Aluminum panel curtain walls excel in harsh environments, thanks to aluminum’s natural ability to form a protective oxide layer. This makes them ideal for coastal or high-humidity areas where corrosion is a major concern. When treated with anodizing or fluorocarbon (PVDF) coatings, these panels resist fading, chalking, and corrosion for over 25 years. Rigorous testing shows minimal degradation even after prolonged exposure to UV rays, acid rain, and salt spray, ensuring long-term aesthetic appeal and structural integrity.

3.2 Structural Strength Meets Lightweight Efficiency

Despite their lightweight composition, aluminum panels offer impressive strength-to-weight ratios. With tensile strengths up to 280 N/mm², they withstand extreme wind loads and seismic forces, making them perfect for high-rise buildings and storm-prone regions. Their lightweight nature reduces overall building load, simplifying structural design and lowering foundation costs. This advantage is particularly critical in earthquake zones or areas with soft soil conditions.

3.3 Aesthetic Versatility and Design Flexibility

Architects favor aluminum panel curtain walls for their design freedom. Available in solid colors, metallic finishes, or wood/stone textures, these panels adapt to any architectural style—from minimalist corporate towers to avant-garde cultural venues. They can be curved, perforated, or combined with glass/metal elements to create dynamic facades. For instance, Shanghai’s Tangchen Yipin residential complex uses gold-anodized panels for a luxurious, modern look, while Dubai’s Princess Tower integrates them into a unitized glass-aluminum system for seamless elegance.

3.4 Thermal Performance and Energy Efficiency

When paired with thermal break technology or insulated cores, aluminum panels significantly enhance energy efficiency. The thermal breaks disrupt heat transfer, reducing indoor temperature fluctuations and HVAC energy consumption by up to 30%. In cold climates, this means lower heating costs; in hot regions, reduced cooling demands. Many systems now incorporate recycled materials or photovoltaic panels, aligning with global sustainability goals and green building certifications like LEED.

3.5 Sustainability and Recyclability

Aluminum is a 100% recyclable material, and curtain wall panels are often made from post-consumer scrap. This closed-loop production minimizes environmental impact, reducing carbon emissions by up to 95% compared to virgin aluminum extraction. With a lifespan exceeding 30 years and minimal maintenance needs, these panels contribute to lower lifecycle costs and reduced construction waste. Their adaptability in renovations further extends their eco-friendly appeal, as existing structures can be updated without demolition.

4. Applications Across Industries

4.1 Commercial Buildings

- Shopping malls, offices, and hotels use aluminum panels for their modern aesthetics and durability.

4.2 Public Spaces

- Airports, hospitals, and museums prioritize their hygiene, acoustic, and maintenance benefits.

4.3 Residential Projects

- High-end apartments and villas adopt them for sleek designs and thermal efficiency.

5. Advantages and Applications of Aluminum Panel Curtain Walls

I. High-Rise Buildings & Commercial Complexes: Structural Efficiency Meets Aesthetic Appeal

In super-tall structures, aluminum panels excel in wind resistance and lightweight properties.

- Shanghai Tower Case Study: The 632-meter skyscraper employs custom aluminum curtain walls optimized via finite element analysis, withstanding 12th-grade typhoon wind loads while reducing structural loads by 18% compared to stone cladding.

- Energy-Efficient Hybrids: Beijing’s CBD integrates glass-aluminum facades, achieving 40% energy savings through adjustable shading coefficients and breathable curtain wall systems.

- Lifecycle Economics: Though initial investments are higher, lifecycle costs are 35% lower than traditional materials, with residual values up to 80% due to recyclability.

II. Residential Buildings: Elevating Aesthetics with Low Maintenance

Premium residential projects leverage aluminum’s durability and design flexibility.

- Hangzhou Luxury Developments: 3mm fluorocarbon-coated panels guarantee 25-year color retention, enhancing property values by 18% in upscale districts.

- Self-Cleaning Technology: Nanocoated panels in Ningbo reduce cleaning costs by 60,000 CNY annually, with 80% less surface contamination than conventional coatings.

- Customization Trends: Shenzhen villa renovations using wood-grain and stone-textured panels saw a 12% premium in resale prices due to enhanced curb appeal.

III. Public Buildings: Functional Durability for High-Traffic Spaces

Public infrastructure demands resilience and aesthetic adaptability.

- Guangzhou Opera House: Double-curved aluminum panels, fabricated with 0.5mm precision via BIM, shortened construction by 40% while creating a cultural landmark.

- Airport Innovations: Shenzhen Airport’s Terminal 4 uses honeycomb-backed panels, achieving 60dB noise reduction and 45% improvement in speech intelligibility.

- Fire Safety Compliance: Convention centers adopt A2-rated fireproof panels, surviving 2-hour fire tests to ensure safe evacuation.

IV. Cultural & Educational Buildings: Green Design Meets Heritage

Institutions prioritize sustainability and occupant comfort.

- Suzhou Second Library: Perforated aluminum panels (35% porosity) boost natural lighting by 30% and cut HVAC energy use by 18%, earning LEED Gold certification.

- Educational Spaces: Low-glare matte panels in Shanghai international schools reduce classroom glare from 82 to 45, complying with EN 12464 lighting standards.

- Cultural Symbolism: Jingdezhen Ceramic Museum integrates laser-engraved blue-and-white patterns into lightweight panels, merging tradition with modern engineering.