Aluminum Composite Panel Curtain Wall Maintenance and Replacement Process: Ensuring Safety and Longevity

Introduction to Aluminum Composite Panel Curtain Walls Aluminum composite panel (ACP) curtain walls have become a cornerstone of modern architecture, prized for their aesthetic versatility, energy efficiency, and eco-friendly properties. These lightweight, durable systems enhance building exteriors while contributing to thermal insulation and reduced environmental impact. However, prolonged exposure to weather, pollution, and natural aging can compromise their structural integrity and visual appeal over time.

Why Maintenance and Replacement Matter Regular maintenance and timely replacement of ACP curtain walls are critical to safeguarding buildings. Neglecting wear and tear risks water infiltration, panel loosening, corrosion, and potential safety hazards. Proactive intervention preserves the structure’s functionality, prevents costly repairs, and maintains its architectural charm.

Key Steps in the Aluminum Composite Panel Curtain Wall Maintenance and Replacement Process

Initial Inspection and Damage Assessment The process begins with a thorough inspection to identify issues such as cracked panels, faded coatings, sealant failure, or frame corrosion. Advanced tools like drones or thermal imaging may detect hidden moisture or insulation gaps.

Safety Preparations and Access Planning Safety protocols, including scaffolding, harnesses, and perimeter barriers, are established. Work schedules are optimized to minimize disruption to building occupants.

Removal of Damaged Panels Damaged panels are carefully detached to avoid harming adjacent sections. Fasteners, sealants, and subframe components are inspected for reuse or replacement.

Subframe Repair and Surface Preparation Corroded or weakened subframes are reinforced or replaced. Surfaces are cleaned, treated for rust, and primed to ensure optimal adhesion for new panels.

Installation of New Aluminum Composite Panels Custom-cut panels matching original specifications are secured using corrosion-resistant fasteners. High-performance sealants are applied to joints to prevent water penetration and air leaks.

Quality Testing and Aesthetic Finishing Post-installation checks verify watertightness, alignment, and structural stability. Coatings or finishes are applied to restore visual uniformity and UV resistance.

Preventive Maintenance Planning A long-term maintenance schedule is recommended, including periodic cleaning, sealant reapplication, and fastener inspections to extend the curtain wall’s lifespan.

Pre-Evaluation in the Aluminum Composite Panel Curtain Wall Maintenance and Replacement Process: Ensuring Precision and Safety

Comprehensive Inspection and Testing A thorough pre-evaluation is the foundation of a successful aluminum composite panel (ACP) curtain wall maintenance and replacement process. This phase identifies existing issues, determines repair urgency, and guides decision-making for long-term solutions.

Visual Inspection Technicians begin by examining the exterior surface of ACP panels for visible damage such as scratches, coating delamination, discoloration, or oxidation. These flaws not only detract from aesthetics but may indicate deeper material degradation.

Structural Integrity Checks Fasteners, brackets, and subframes are inspected for looseness, corrosion, or warping. Aging signs like weakened joints or deformed panels are documented, as these compromise the curtain wall’s load-bearing capacity and weather resistance.

Advanced Non-Destructive Testing (NDT) Tools like infrared thermography and ultrasonic scanners are used to detect hidden defects. Infrared identifies moisture traps or insulation gaps, while ultrasonic testing reveals internal cracks or bonding failures within panels.

Data Documentation and Root Cause Analysis

Detailed Problem Mapping All identified issues—such as water leakage points, fastener failures, or panel deformities—are cataloged with photos, measurements, and location tags. This creates a visual “damage map” for targeted action.

Root Cause Investigation Data is analyzed to determine whether failures stem from installation errors (e.g., improper sealing), environmental factors (UV exposure, pollution), or material defects (substandard coatings or core layers).

Risk Assessment and Strategic Planning

Safety and Operational Risk Evaluation Hazards like falling debris from loose panels or electrical risks near corroded frames are prioritized. Site-specific challenges—such as working at height or around occupied spaces—are factored into safety protocols.

Budget and Timeline Development Costs are calculated based on panel replacement ratios, labor intensity, and material sourcing. A phased timeline is created, balancing urgency (e.g., immediate leaks) with long-term needs (full-section upgrades). Resource allocation includes equipment rentals, waste disposal plans, and contingency measures for weather delays.

Aligning with the Aluminum Composite Panel Curtain Wall Maintenance and Replacement Process This pre-evaluation phase directly informs whether localized repairs or full-scale replacements are required. For instance, widespread subframe corrosion may necessitate a complete overhaul, while isolated panel damage could be addressed through spot repairs. The findings also guide material selection—opting for higher UV-resistant coatings or fire-rated cores if prior failures were linked to environmental stressors.

By integrating these assessments into the aluminum composite panel curtain wall maintenance and replacement process, stakeholders minimize guesswork, reduce costs, and ensure compliance with international building codes. This proactive approach transforms reactive fixes into sustainable solutions, extending the structure’s lifespan while preserving its functional and visual integrity.

Preparation Phase in the Aluminum Composite Panel Curtain Wall Maintenance and Replacement Process

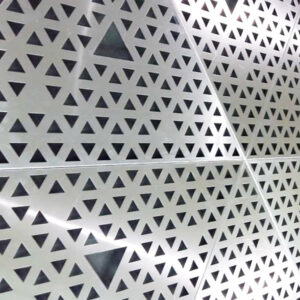

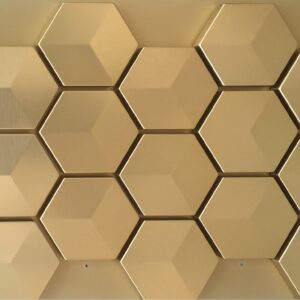

Material Preparation: Ensuring Consistency and Quality A critical step in the aluminum composite panel curtain wall maintenance and replacement process is sourcing materials that match the original specifications. High-quality aluminum composite panels (ACPs) are selected to replicate the existing system’s color, thickness, finish, and fire resistance ratings. Suppliers must verify batch consistency to avoid mismatches in texture or gloss levels, which could disrupt visual harmony. Adhesives, sealants, and fasteners are also procured to meet or exceed industry standards, ensuring long-term durability against weather and structural stress.

Tool and Equipment Readiness

Standard Tools Basic tools such as screwdrivers, drills, torque wrenches, and lifting gear (e.g., cranes or gondolas) are inspected for functionality. Backup tools are kept on-site to avoid delays caused by equipment failure.

Specialized Machinery Elevated work platforms, scaffolding systems, and fall protection gear (harnesses, guardrails) undergo rigorous safety checks. Testing ensures machinery like hydraulic lifts operates smoothly at heights, while cutting tools for panel customization are calibrated for precision.

Team Assembly and Training

Skilled Workforce Selection Experienced technicians familiar with the aluminum composite panel curtain wall maintenance and replacement process are prioritized. Teams typically include installers, welders, inspectors, and safety supervisors to cover all aspects of the project.

Comprehensive Training Crews receive task-specific briefings covering:

- Safety protocols for working at heights and handling heavy panels.

- Technical skills, such as proper sealing techniques or fastener torque settings.

- Emergency response drills for scenarios like sudden weather changes or equipment malfunctions.

Site Setup and Safety Coordination

Work Zone Demarcation The construction area is clearly marked with barriers, warning signs, and access restrictions to protect occupants and pedestrians. Temporary covers may shield adjacent sections from dust or debris during panel removal.

Logistics Planning

- Material Storage: Panels and tools are stored in designated dry, secure areas to prevent damage or theft.

- Waste Management: Recycling bins for old panels and hazardous waste containers for sealant residues are positioned for efficient disposal.

- Emergency Protocols: Evacuation routes, first-aid stations, and communication channels are established to address accidents swiftly.

Aligning with the Aluminum Composite Panel Curtain Wall Maintenance and Replacement Process Thorough preparation minimizes downtime and errors during execution. For instance, color-matching panels in advance avoids costly rework, while trained crews reduce the risk of improper installations that could lead to water leaks or panel detachment. Safety-focused site planning not only complies with regulations like OSHA but also fosters trust among building occupants.

By meticulously addressing material quality, equipment reliability, team competency, and site safety, this phase lays the groundwork for a seamless aluminum composite panel curtain wall maintenance and replacement process. It transforms theoretical plans into actionable steps, ensuring the project stays on schedule, within budget, and aligned with the structure’s functional and aesthetic requirements.

Step-by-Step Execution in the Aluminum Composite Panel Curtain Wall Maintenance and Replacement Process

1. Removal of Damaged Panels

The aluminum composite panel curtain wall maintenance and replacement process begins with the systematic removal of compromised panels. A precision removal plan is developed to protect adjacent panels and underlying structures. Technicians use non-destructive tools to detach fasteners, minimizing vibration or pressure that could cause collateral damage. Removed panels and hardware are sorted for recycling or disposal, adhering to environmental regulations. Safety nets or debris-catching systems are deployed to prevent falling materials during this phase.

2. Installation of Replacement Panels

Material Verification New aluminum composite panels (ACPs) undergo rigorous quality checks. Dimensions, color consistency, coating integrity, and fire ratings are validated against original specifications to ensure seamless integration.

Precision Positioning Laser-guided alignment tools and vacuum lifters position replacement panels accurately. Temporary brackets or clamps hold panels in place while allowing micro-adjustments for perfect alignment with neighboring sections.

Secure Fastening Corrosion-resistant fasteners (e.g., stainless steel screws or rivets) are installed at pre-engineered intervals. High-performance structural sealants are applied to panel edges, followed by compression to create airtight, water-resistant bonds.

3. Joint and Seam Sealing

Critical joints, corners, and panel intersections receive specialized attention. Surfaces are cleaned, primed, and layered with premium polyurethane or silicone sealants. Backer rods may be inserted into wide gaps to optimize adhesion and flexibility. For curved or complex geometries, custom-formulated sealants are used to accommodate thermal expansion and movement.

4. On-Site Quality Assurance Testing

Visual and Structural Inspection QA teams conduct a post-installation review, checking for:

- Panel alignment, flushness, and color uniformity.

- Proper fastener torque values using calibrated tools.

- Smooth, continuous sealant lines without bubbles or gaps.

Performance Validation

- Water Penetration Test: Controlled water spray evaluates drainage and sealing effectiveness.

- Air Infiltration Test: Blower doors or smoke pencils detect leaks in the curtain wall system.

- Load Testing: Non-invasive stress tests verify panel stability under wind or seismic simulations.

Integration with the Aluminum Composite Panel Curtain Wall Maintenance and Replacement Process Each step is documented with photos, test results, and compliance certificates. For example, sealant cure times are tracked to avoid premature exposure to rain, while fastener torque logs ensure consistency. Any deviations are addressed immediately—such as resealing a joint or replacing a misaligned panel—to prevent long-term performance issues.

This phase transforms preparatory work into tangible results, balancing technical precision with practical execution. By adhering to the aluminum composite panel curtain wall maintenance and replacement process, teams achieve durable repairs that restore structural resilience, weatherproofing, and visual continuity. The systematic approach minimizes operational disruptions, ensuring the building remains safe and functional throughout the project lifecycle.

Comprehensive Guide to Aluminum Panel Curtain Wall Repair and Replacement Process

Proper maintenance and timely repairs are critical to ensuring the longevity and performance of aluminum panel curtain wall systems. This guide outlines essential practices for preserving these structures, with a focus on the aluminum panel curtain wall repair and replacement process.

1. Post-Installation Care & Maintenance Regular inspections and cleaning form the foundation of effective upkeep for aluminum curtain walls.

a. Scheduled Inspections & Cleaning

- Establish a routine inspection plan (bi-annual or quarterly) to assess panels for dents, corrosion, or coating wear.

- Clean surfaces using neutral pH cleaning agents and soft-bristle tools to avoid scratching finishes.

- Remove debris from joints and drainage channels to prevent water accumulation.

b. Proactive Monitoring During the aluminum panel curtain wall repair and replacement process, prioritize early detection of issues like loose fasteners or misaligned panels. Check weather seals and gaskets for degradation, especially after extreme weather events.

2. Documentation & Feedback Systems Accurate records and responsive communication streamline maintenance workflows.

a. Detailed Logging Document all inspections, test results (e.g., water resistance, wind load performance), and repair actions. Archive photos and notes from each phase of the aluminum panel curtain wall repair and replacement process for future reference.

b. Feedback Integration Create open channels for contractors, engineers, and building managers to report recurring issues. Use data to refine maintenance schedules or adjust materials for improved durability.

3. Preventive Maintenance Strategies Anticipate and address vulnerabilities to minimize costly repairs.

a. Surface Protection Apply touch-up coatings or localized repainting to areas exposed to UV radiation or pollution. During the panel aluminum curtain wall repair and replacement process, prioritize high-quality primers and paints to extend service life.

b. Sealant Management Inspect silicone or polyurethane sealants annually for cracks, hardening, or adhesion loss. Replace deteriorated sealants promptly to maintain thermal efficiency and waterproofing.

c. Structural Reinforcement Reinforce support brackets or framing components in high-stress zones. Schedule professional assessments every 5–7 years to evaluate system integrity.

Key Steps in the Aluminum Panel Curtain Wall Repair and Replacement Process

- Damage Assessment: Identify compromised panels, fasteners, or seals.

- Safe Removal: Use specialized tools to detach damaged panels without affecting adjacent units.

- Preparation: Clean substrate surfaces and apply corrosion inhibitors if needed.

- Installation: Secure new panels with precision-aligned brackets and updated sealing techniques.

- Quality Check: Verify alignment, sealant curing, and overall system performance.

By integrating regular maintenance with a structured aluminum panel curtain wall repair and replacement process, building owners can optimize safety, aesthetics, and energy efficiency. Partner with certified professionals to ensure compliance with industry standards and manufacturer guidelines.

Common Issues & Solutions in the Aluminum Panel Curtain Wall Repair and Replacement Process

Maintaining aluminum panel curtain walls requires addressing recurring challenges to prevent system failures. Below, we explore frequent problems, emergency fixes, and real-world examples tied to the aluminum panel curtain wall repair and replacement process.

1. Common Fault Analysis Understanding root causes helps streamline repairs and extend curtain wall lifespan.

a. Surface Scratches, Oxidation, or Coating Detachment

- Causes: Abrasion from debris, UV exposure, or improper cleaning methods.

- Solutions:

- For minor scratches: Polish affected areas using non-abrasive compounds.

- Address oxidation by sanding and reapplying anti-corrosion coatings.

- Replace panels with severe coating detachment during the aluminum panel curtain wall repair and replacement process.

b. Loose Fasteners & Sealant Failure

- Causes: Thermal expansion, vibration, or aging materials.

- Solutions:

- Tighten or replace loose screws, bolts, or anchors immediately.

- Remove degraded sealants and reapply high-performance alternatives (e.g., silicone or polyurethane).

2. Emergency Response Measures Act swiftly to mitigate risks and minimize downtime.

a. Rapid Repair Solutions

- Localized Cleaning & Re-sealing:

- Clean damaged areas with alcohol-based solvents to remove contaminants.

- Inject fresh sealant into gaps, ensuring full adhesion during the aluminum panel curtain wall repair and replacement process.

- Fastener Reinforcement:

- Install secondary brackets or adhesive-backed supports for temporary stability.

b. Emergency Protocol Development Create a step-by-step response plan for scenarios like panel detachment or water leakage. Train maintenance teams to prioritize safety (e.g., cordoning off hazardous zones) and use specialized tools.

3. Case Studies Learn from practical applications of the aluminum panel curtain wall repair and replacement process.

a. Successful Repair Example

- Issue: A 10-year-old office building faced frequent water infiltration due to cracked sealants.

- Solution:

- Identified faulty seals using thermal imaging and moisture meters.

- Executed the aluminum panel curtain wall repair and replacement process: removed 15 damaged panels, upgraded sealants to weather-resistant variants, and reinstalled units.

- Outcome: Eliminated leaks and reduced energy costs by 12% through improved insulation.

b. Lessons from a Failed Project

- Issue: A rushed repair job used low-grade fasteners, causing panel misalignment within 6 months.

- Root Cause: Skipping load-bearing assessments during the aluminum panel curtain wall repair and replacement process.

- Improvements:

- Implement mandatory structural checks before repairs.

- Source certified materials compliant with local building codes.

Key Takeaways for the Aluminum Panel Curtain Wall Repair and Replacement Process

- Preventative Diagnostics: Regular inspections reduce emergency repairs.

- Material Quality: Never compromise on sealants, coatings, or fasteners.

- Training & Compliance: Ensure teams follow standardized protocols and safety guidelines.

By addressing common faults systematically and refining the aluminum panel curtain wall repair and replacement process, building operators can enhance durability, aesthetics, and cost-efficiency. Always collaborate with accredited contractors to guarantee precision and regulatory adherence.