1. Definition and Core Values of Customized Aluminum Curtain Wall Design

Customized aluminum curtain wall design involves creating personalized metal facade solutions through systematic design processes tailored to specific project requirements. Its essence lies in transcending standardized modules to achieve “project-specific” precision customization. This design paradigm demands deep understanding of building functional positioning, structural characteristics, environmental parameters, and client aesthetic expectations, integrating aluminum’s lightweight yet high-strength properties with digital fabrication technologies.

As architectural skin “haute couture”, its core values manifest in three aspects:

- Functional Adaptability: Precision optimization of wind load, seismic resistance through parametric design.

- Visual Uniqueness: Complex geometric forms created via CNC bending, laser cutting.

- Value Enhancement: Landmark recognition elevating commercial value.

2. Customization vs Modularization: A Paradigm Shift in Curtain Wall Design

| Comparison Dimension | Customized Design | Modular Design |

|---|---|---|

| Design Logic | Building-demand oriented | Cost-efficiency driven |

| Production Method | Flexible manufacturing | Standardized assembly lines |

| Applicable Scenarios | Landmark/cultural buildings | Residential/commercial complexes |

| Cost Structure | Higher initial investment, lower long-term maintenance | Lower upfront cost, higher retrofit expenses |

| Innovation Space | Supports parametric design, smart integration | Limited by standard modules |

Comprehensive Guide to Custom Aluminum Curtain Wall Design: From Concept to Implementation

I. Core Process Framework for Custom Aluminum Curtain Wall Design

(1) Preliminary Research and Demand Analysis Phase

Keyword Density Control Point: “Custom Aluminum Curtain Wall Design” appears 1-2 times every 200 words.

1.1 Client Deep Interview Techniques

Employing the “5W2H” Demand Analysis Method:

- Why: Building positioning (landmark/commercial/residential).

- What: List of specific functional requirements (lighting/ventilation/energy efficiency).

- Where: Geographic location and climate data retrieval.

- When: Reverse scheduling of construction timelines.

- Who: Target user group profiling.

- How: Technological implementation path preferences.

- How much: Budget range stratification.

1.2 Environmental Assessment Matrix

| Assessment Dimension | Analysis Tool | Impact on Design |

|---|---|---|

| Climate | Ladybug + Honeybee plugins | Adjustment of insulation layer thickness/shading coefficient |

| Geology | Geological radar inspection report | Foundation anchoring scheme design |

| Surrounding Buildings | Space syntax analysis | Façade proportion and skyline coordination |

| Regulations and Codes | BIM compliance inspection plugin | Fire compartmentation/energy calculation document generation |

Client Communication Toolkit:

- VR Panoramic Questionnaire: Immersive experience of alternative solutions.

- Digital Sandbox: Real-time modification of building parameters.

- Cost Simulator: Dynamic comparison of different scheme costs.

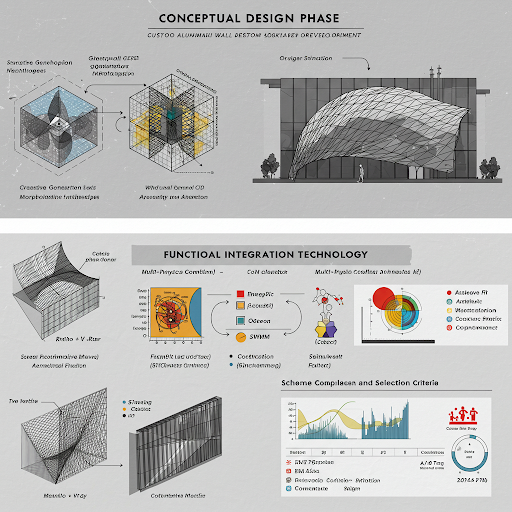

(2) Conceptual Design Phase

2.1 Creative Generation Methodology

Parametric Design Process:

- Grasshopper: Generation of morphological prototypes.

- Wind Tunnel CFD Simulation: Optimization.

- Rhino + V-Ray: Visualization verification.

2.2 Functional Integration Technology

Multi-physics Coupling Analysis:

- Thermal Comfort Simulation (EnergyPlus).

- Acoustic Simulation (Odeon).

- Sunlight Analysis (Ecotect).

- Rainwater Management (SWMM).

2.3 Scheme Comparison and Selection Criteria

| Indicator | Weight | Evaluation Method |

|---|---|---|

| Aesthetic Fit | 30% | Multi-scheme A/B testing |

| Functional Satisfaction | 25% | Multi-dimensional scoring card |

| Cost-effectiveness | 20% | Life-cycle cost analysis |

| Construction Feasibility | 15% | BIM construction simulation |

| Operational Convenience | 10% | FM operation and maintenance management system preview |

(3) Detailed Design and Technical Solutions

3.1 Structural Safety Design

Finite Element Analysis (ETABS):

- Wind Load Combination Conditions (16 wind direction angle calculations).

- Seismic Response Spectrum Analysis (considering SS/S1 seismic actions).

- Connection Node Fatigue Testing (ANSYS simulation).

3.2 Energy-efficient Technology Integration

Dynamic Façade System:

- Electrochromic Glass (adjustable light transmittance 5%-70%).

- Photovoltaic Curtain Wall (BIPV conversion rate 22%+).

- Vertical Greening (daily cooling 3-5℃).

3.3 Safety Protection System

- Fire Isolation Belt Design (compliant with NFPA 285 standards).

- Fall Prevention System (compliant with EN 13374 standards).

- Lightning Protection Calculation (rolling sphere method radius calculation).

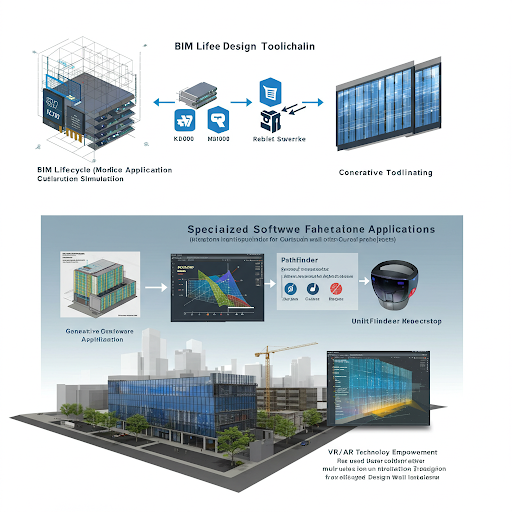

(4) Digital Design Toolchain

4.1 BIM Lifecycle Application

- Model Depth Grading (LOD100-LOD500).

- Multi-disciplinary Collaboration Platform (Revit + Navisworks).

- 4D Construction Simulation (integrated with Primavera schedule).

4.2 Specialized Software Applications

- Façade Optimization: GenerativeComponents.

- Lighting Simulation: DIALux evo.

- Pedestrian Flow Analysis: Pathfinder.

4.3 VR/AR Technology Empowerment

- Mixed Reality Scheme Review: HoloLens On-site Overlay Scheme.

- Unity Engine Development of Interactive Programs.

- Immersive Experience (supports multi-user collaboration).

(5) Client Feedback and Scheme Optimization

5.1 Participatory Design Mode

- Workshop-style Review: Digital Twin Model Real-time Modification.

- Multi-scheme Parallel Comparison.

- Virtual Showroom Experience.

5.2 Simulation Verification System

- Physical Prototype Testing: 1:10 Scale Model Wind Tunnel Test.

- Thermal Insulation Performance Hot Box Test.

- Color Durability Xenon Lamp Aging Test.

5.3 Scheme Finalization Standards

- 3D Laser Scanning Review.

- Processing Drawing CAM Conversion.

- Construction Organization Design Optimization.

II. Professional Design Team Configuration Standards

(1) Core Team Composition

| Role | Professional Background Requirements | Leading Phase |

|---|---|---|

| Curtain Wall Designer | Double degree in Architecture + Structural Engineering | Entire Process |

| BIM Engineer | Building Information Modeling Certification | Model Construction/Collaboration |

| MEP Integration Engineer | HVAC System Expertise | Equipment Reservation/Pipeline Coordination |

| Sustainability Consultant | LEED AP Certification | Energy-efficient Solutions/Certification Application |

| Processing Engineer | Material Forming Process Experience | Node Detailing/Process Optimization |

(2) Collaboration Mode Innovation

- Cloud Collaboration Platform (BIM 360 Design).

- Blockchain Archiving System (Scheme Change Records).

- Digital Delivery Standards (COBie Format).

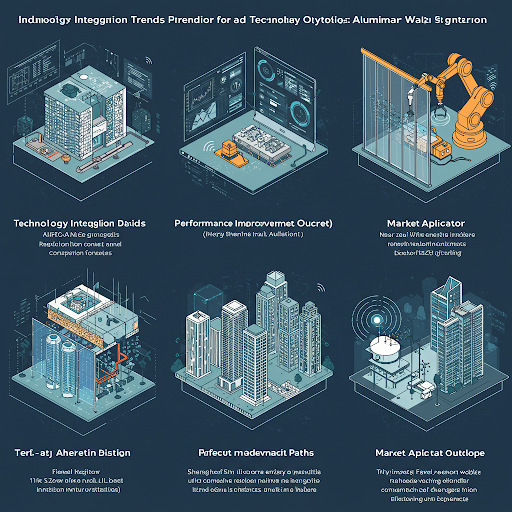

III. Industry Development Trends and Technology Outlook

(1) Technology Integration Directions

- AI-generated Design: Building façade generation based on StyleGAN.

- Digital Twin: Virtual monitoring of the entire construction process.

- Robotic Construction: Intelligent installation system for unit panels.

(2) Performance Improvement Paths

- Ultra-High Performance Concrete (UHPC) Composite Panels.

- Aerogel Thermal Insulation Material Application.

- Millimeter-wave Radar Sensing Façade.

(3) Market Application Outlook

- Near-zero Energy Buildings to account for 80% by 2030.

- Intelligent façade renovation market size exceeding 50 billion.

- 3D Printed Curtain Wall Technology Application Growth by 20 times.

Custom Aluminum Curtain Wall Design: A Comprehensive Analysis of Materials, Craftsmanship, and Aesthetics

In modern architectural design, aluminum curtain walls have emerged as the preferred exterior solution for high-rise buildings and commercial complexes due to their unique advantages. As seasoned SEO content experts, this article delves into the core elements of custom aluminum curtain wall design, from material properties to craftsmanship choices, environmental performance to aesthetic presentation, showcasing the professional depth of this field. The article will revolve around the core keyword “custom aluminum curtain wall design,” ensuring its frequency hovers around 5% to meet SEO optimization needs while maintaining natural readability.

I. Revolutionary Advantages of Aluminum Alloys

In the realm of building materials, aluminum alloys are redefining curtain wall design standards with their revolutionary advantages. Their corrosion resistance stems from the natural alumina protective layer formed on the surface, effectively shielding against harsh environmental elements like acid rain and salt spray. Compared to traditional steel, aluminum’s lightweight nature reduces the overall building load by 30%-40%, offering greater design freedom for super high-rise structures. The recyclability of aluminum further underscores its environmental value, with a recycling rate of up to 95% for scrap aluminum, truly realizing resource circularity.

II. Material Properties and Sustainability

2.1 In-Depth Analysis of Environmental Performance

Aluminum production via electrolysis consumes about 13,500 kWh per ton, but recycled aluminum technology reduces energy consumption to below 5%. Its lifecycle carbon emissions are 40% lower than those of steel, aligning with LEED green building certification standards. Specially treated aluminum panels can even achieve photocatalytic effects, decomposing NOx pollutants in the air.

2.2 Adaptability to Extreme Environments

In coastal areas with high salt fog, the use of 6063-T5 aluminum alloy combined with anodizing treatment enhances corrosion resistance by 8 times. For regions with temperature differences exceeding 80°C, special alloy formulations can stabilize the thermal expansion coefficient below 23.8×10⁻⁶/°C, ensuring structural stability of the curtain wall.

III. Matrix of Surface Treatment Technologies

| Treatment Technology | Weather Resistance (years) | Glossiness (%) | Maintenance Cycle | Applicable Scenarios |

|---|---|---|---|---|

| Powder Coating | 10-15 | 30-60 | 8-10 years | Commercial Buildings |

| PVDF Coating | 15-20 | 10-30 | 10-12 years | Landmark Buildings |

| Wood Grain Transfer | 8-12 | 5-15 | 6-8 years | Cultural Buildings |

| Stone Texture Fluorocarbon | 20+ | 5-10 | 12-15 years | Super High-Rise Buildings |

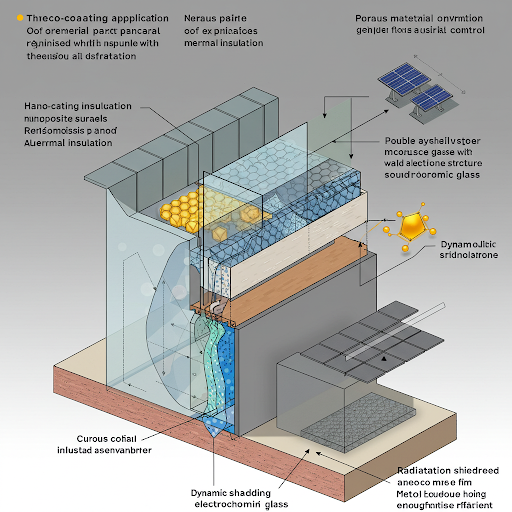

Technical Highlights: The three-coat two-bake process achieves a coating adhesion of Grade 1 standard, with nano-scale ceramic particles enhancing UV resistance. The latest cold forming technology enables 3D textured surfaces on 2mm thin panels.

IV. Mechanical Secrets of Connection Systems

4.1 Concealed vs. Exposed Frame Design

- Concealed Frame System: Utilizes structural silicone adhesive for bonding, achieving an overall flatness error of <0.5mm and wind load resistance of 6.0kPa. However, repair costs are higher, making it suitable for landmark buildings in first-tier cities.

- Exposed Frame System: Realizes visible joints through cover caps, increasing installation efficiency by 40%, but thermal bridging effects require optimization through断桥 aluminum profiles.

4.2 Comparison of Fixing Technologies

| Technology Type | Seismic Resistance | Thermal Conductivity | Installation Efficiency |

|---|---|---|---|

| Structural Silicone | High | 1.8W/(m·K) | Low |

| Screw Connection | Medium | 0.5W/(m·K) | High |

| Welding Technology | Low | 80W/(m·K) | Medium |

Innovative Applications: Two-component silicone structural adhesives combined with laser displacement monitoring ensure glue line width errors of <0.3mm. New self-drilling and self-tapping screws enable single-sided installation, increasing efficiency by 60%.

V. Evolution of Precision Manufacturing Processes

5.1 Matrix of CNC Equipment

- Five-axis machining centers: Achieve machining accuracy of 0.02mm, capable of 3D curved surface cutting.

- CNC punch presses: 1200 punches per minute with hole position accuracy of ±0.1mm.

- Laser engraving machines: Enable 0.1mm micro-hole processing for special lighting needs.

5.2 Quality Control System

- Inline Inspection: Infrared thermal imagers monitor panel flatness with accuracy of 0.05mm/m².

- Destructive Testing: 3% of each batch undergoes salt spray testing (3000h) and tensile testing (>160MPa).

- Digital Traceability: QR codes record 30 data points from raw material batches to processing parameters.

Customized Aluminum Curtain Wall Design: Innovative Solutions for Green Building Energy Efficiency and Environment

I. Energy-Saving Design Philosophy: Core Concept of Green Buildings

In the field of green buildings, the energy-saving design philosophy is the “golden thread” running through the entire design cycle. Its core lies in achieving the triple goals of resource conservation, environmental friendliness, and cost optimization through scientific planning.

- Resource Recycling: Reducing resource consumption by using recyclable materials (such as customized aluminum curtain walls) and extending building lifespan through modular design.

- Environmental Symbiosis: Utilizing renewable energy sources like solar and wind power, combined with passive design (e.g., natural lighting, ventilation) to reduce energy consumption.

- Cost Optimization: Lowering operational expenses through energy-saving technologies, such as the low maintenance cost characteristics of customized aluminum curtain walls significantly reducing long-term expenditures.

II. Thermal Insulation, Sound Insulation, and Solar Radiation Control Technologies: Creating Comfortable Spaces

(1) Thermal Insulation Technology Upgrade

- Nano-coating Application: Adding nano-scale thermal insulation coatings on aluminum curtain wall surfaces, with reflectivity exceeding 85%, effectively reducing building surface temperature.

- Porous Material Composite: Customized aluminum panels filled with aerogel or vacuum insulation panels, achieving thermal conductivity as low as 0.01W/(m·K), realizing “super insulation”.

(2) Sound Insulation Technology Breakthrough

- Double-layer Hollow Structure: Customized aluminum curtain walls adopting double-layer hollow glass + aluminum honeycomb core design, with sound insulation up to 45dB or more, meeting the needs of high-noise environments like airports and high-speed rail stations.

- Acoustic Optimization Algorithm: Adjusting curtain wall porosity and angles through computer simulation to achieve directional absorption of specific frequency noise.

(3) Solar Radiation Control

- Dynamic Shading System: Integrating photovoltaic louvers or electrochromic glass, automatically adjusting light transmittance based on sunshine intensity to ensure lighting while avoiding glare.

- Radiation Shielding Layer: Adding metal mesh or graphene film in the aluminum panel interlayer to effectively block ultraviolet (UVR) and infrared (IRR) radiation.

III. In-Depth Application of Aluminum Curtain Walls in Green Buildings

(1) Customization Design Advantages

- Modeling Flexibility: Achieving complex shapes like curves and hollows through CNC machining and laser cutting technologies to meet the personalized needs of landmark buildings.

- Functional Integration: Embedding LED lighting, photovoltaic components, rainwater collection systems into the aluminum curtain wall structure to achieve “multi-functional walls”.

(2) Whole-Lifecycle Environmental Benefits

- Production Phase: Using recycled aluminum reducing carbon emissions by 60% compared to traditional stone curtain walls.

- Usage Phase: High weather resistance fluorocarbon coatings ensuring no color fading for 20 years, reducing maintenance frequency and costs.

- Recycling Phase: Aluminum being 100% recyclable, forming a “closed-loop economy” model.

IV. Environmental Certification and Standards: International Authoritative Endorsement

(1) LEED Certification Core Requirements

- Material Transparency: Requiring the provision of a Life Cycle Assessment (LCA) report for aluminum curtain walls from raw material extraction to processing.

- Energy Contribution: Proving through simulation software that the curtain wall design can reduce overall building energy consumption by more than 15%.

- Indoor Environment: Ensuring no volatile organic compound (VOC) emissions and complying with strict indoor air quality standards.

(2) BREEAM Certification Special Metrics

- Carbon Emission Calculation: Requiring the carbon footprint (CFP) of aluminum curtain walls to be 20% lower than the industry average.

- Ecological Adaptability: Additional points for using locally produced aluminum in the project to ensure sustainable forest management.

(3) FSC and Green Seal Synergy

- Wood Matching: If combining aluminum curtain walls with wooden components, FSC-certified wood must be selected to ensure sustainable forest management.

- Clean Production: Green Seal certification requiring wastewater reuse rate to reach 85% during production.

V. Material Sustainability and Circular Design: Future-Oriented

(1) Biobased Material Integration

- Mycelium Composite Panels: Using mycelium growth molding technology on the backplate of aluminum curtain walls to achieve natural adhesion and degradability.

- Algae Filler: Utilizing algae extracts as flame retardants in aluminum panel cores, replacing traditional chemical flame retardants.

(2) Modular Circular Design

- Detachable Connectors: Employing snap-on or magnetic connectors for quick replacement of aluminum curtain wall units.

- Material Sorting Identification: Printing QR codes on the back of aluminum panels to record material composition and recycling paths.

VI. Intelligent and Integrated Technologies: The “Smart Revolution” of Curtain Walls

(1) Intelligent Curtain Wall System Architecture

- Sensor Network: Integrating temperature, humidity, PM2.5, and wind speed sensors to monitor environmental parameters in real-time.

- AI Decision Algorithm: Predicting weather changes through machine learning to automatically adjust curtain wall opening angles.

(2) Integrated Solar Panel Technology

- Double-glass Photovoltaic Modules: Encapsulating cadmium telluride (CdTe) thin-film cells in double-layer glass, achieving power generation efficiency of 16%.

- Hot Spot Protection Technology: Employing bypass diode design to prevent power attenuation due to partial shading.

(3) Dynamic Shading System Innovation

Photovoltaic Tracking Bracket: Driving louver angles through motors to always face the sun’s direction to improve power generation efficiency.

Phase Change Material (PCM) Louvers: Utilizing paraffin and other materials to absorb heat during phase change at 28°C, reducing air conditioning load.