When extreme weather plays dirty, Aluminum Curtain Walls with PVDF fight back—no fading, no flaking, just decades of flawless armor.

When you’re building with Aluminum Curtain Walls in places that roast, freeze, or salt-blast your walls six ways from Sunday, your finish better have backbone. We’re talkin’ desert heat that peels paint like a bad sunburn and coastal air so salty it could pickle steel. And yet—some folks still gamble on coatings that look good for a year… then start flaking out like a fair-weather friend.

Here’s the kicker: According to the American Architectural Manufacturers Association (AAMA 2605), PVDF coatings can hold up for over 20 years without fading or chalking—even under relentless UV assault and hurricane-force conditions. That’s not just marketing fluff—it’s industry gospel backed by decades of testing.

If you’re footing the bill for high-rise facades, you don’t want callbacks five years down the line because someone cheaped out on coating. This is where PVDF earns its keep—and maybe even saves yours.

Understanding PVDF Coating and Its Role in Harsh Climates

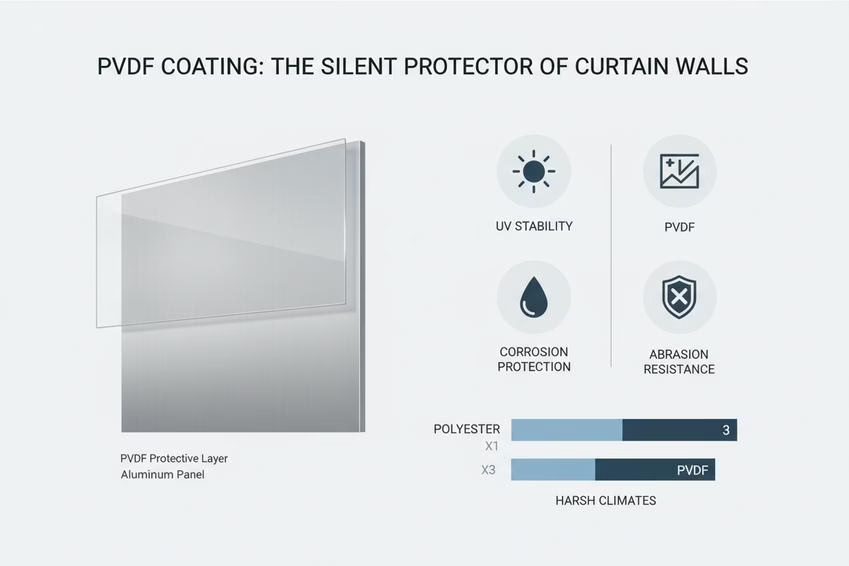

PVDF coatings are the silent protectors behind long-lasting, weather-resistant aluminum curtain walls. Let’s break down how they work their magic.

Why PVDF Outperforms Other Surface Finishes in Extreme Environments

- Superior UV stability: PVDF resins resist breakdown under intense sunlight, keeping color fade at bay.

- High-end corrosion protection: Perfect for salty coastal air or industrial pollution.

- Tough on abrasion: It stands up to sandstorms, hail, and even careless window washers.

According to a recent report by the Global Building Envelope Association (2024), curtain wall systems using PVDF coatings last up to three times longer than those with polyester finishes — especially where humidity and temperature swings are brutal.

How PVDF Coatings Interact with Aluminum Alloy Composition and Thermal Expansion

When it comes to dealing with heat waves or icy snaps, aluminum alloys move — literally. That’s where PVDF steps up:

- It bonds tightly thanks to excellent interfacial bonding, preventing peeling during expansion.

- The coating stays flexible without cracking — a win for thermal cycling.

- Its chemical compatibility with most architectural-grade aluminum alloys makes it ideal for structural applications.

That means fewer maintenance calls and zero weird warping across your curtain wall panels.

From Extrusion Process to Quality Control: How PVDF Is Applied to Curtain Wall Panels

Here’s how those slick surfaces come together:

• Pre-treatment starts the process by cleaning and preparing the aluminum surface for strong adhesion.

• A uniform coat of powdered PVDF is applied via electrostatic spray guns during the main application phase.

• The panel then moves into a curing oven where the coating chemically fuses with the metal substrate.

Once cooled, every batch goes through strict testing — including checks on coating thickness, gloss level, and scratch resistance — before heading out for installation on modern buildings rocking sleek aluminum curtain walls.

4 Key Benefits of PVDF Coatings for Aluminum Curtain Walls

PVDF coatings bring serious perks to aluminum curtain walls, especially when you’re dealing with tough weather, tall buildings, or long-term upkeep.

Long-Term Corrosion Resistance Under Wind Load and Coastal Conditions

- PVDF coating stands up to salty air and wild wind without flinching.

- It forms a tight molecular bond with the metal, locking out moisture that leads to rust.

- Even in hurricane-prone areas, it keeps aluminum curtain walls strong and intact.

✓ In coastal zones where salt spray is a daily visitor, corrosion resistance matters more than looks. The chemical stability of PVDF means fewer repairs and way less stress during storm season. It doesn’t flake or peel—even when heavy gusts slam against the surface for years on end. That’s long-haul durability you can count on.

Color Stability and Surface Finish Consistency Across Large Panel Dimensions

- Uniform color tone across wide façades? Check.

- No chalking or fading even after years under UV rays? Also check.

- Gloss retention that keeps your building looking fresh? Triple check.

According to a 2024 report by Global Construction Coatings Review, over 82% of architects now specify PVDF coating for large-scale cladding projects due to its unmatched color stability and fade resistance under high solar exposure.

That’s not just aesthetics—it’s about keeping your building from aging prematurely.

Reduced Maintenance Costs Through Durable Finishing and Extended Warranty Terms

• Lower cleaning frequency

• Less repainting over time

• Longer finish warranties (up to 30 years)

The secret sauce here is how the durable finishing resists grime buildup, mold growth, and harsh weather effects—making maintenance practically an afterthought. Add in extended warranties from most manufacturers, and you’re looking at major savings across the lifecycle of any aluminum curtain wall system.

Fire Rating and Safety Compliance for High-Rise Curtain Wall Systems

High-rise buildings don’t mess around with safety codes:

- Class A fire rating ensures low flame spread

- Meets international standards like NFPA 285

- Helps maintain integrity of full curtain wall systems

When you’re stacking floors sky-high, fire compliance isn’t optional—it’s critical. Thanks to its formulation, PVDF coating helps your façade meet strict safety rules while still holding onto its good looks. That peace of mind? Worth every penny when lives are involved—or when inspectors come knocking.

How to Choose the Right PVDF Coating for Your Aluminum Curtain Wall

Get the lowdown on picking the perfect PVDF finish for your aluminum curtain wall, from climate tweaks to cost hacks.

Matching PVDF Performance with Panel Thickness, Weight, and Edge Treatment

- Thicker panels often demand higher-performance coatings due to increased surface exposure.

- Lightweight panels can flex more, requiring flexible yet durable coatings.

- Sharp or exposed edges? Prioritize edge-sealing properties in your PVDF selection.

When evaluating PVDF performance, think beyond aesthetics—focus on how it interacts with panel geometry. A heavier aluminum sheet needs a tougher coating that won’t crack under stress. On the flip side, thinner panels benefit from lighter formulations that don’t compromise flexibility. And if you’re dealing with custom-cut edges or perforations, make sure your coating wraps and seals those spots like a pro.

Climate-Driven Selection: UV Exposure, Temperature Swings, and Thermal Expansion

You want your aluminum curtain walls to shine through scorching summers and icy winters? Then listen up:

- High UV zones need enhanced fade resistance—go for high-grade fluoropolymer blends.

- Big temperature swings call for coatings that expand without peeling or chalking.

- Coastal or humid climates? Add salt-spray resistance into your checklist.

Thermal movement in aluminum is real—and relentless. Choosing a coating that stretches along with the metal keeps things intact through every season shift.

Coordinating PVDF Finishes with Framing Systems, Gaskets, and Drainage Systems

• Match finishes to framing systems: color consistency matters across mullions and spandrels.

• Confirm gasket compatibility: some chemicals in sealants can react poorly with certain PVDF finishes.

• Drainage systems must not trap moisture behind coated surfaces—ventilation is key.

System coordination isn’t just about looks—it’s about keeping water out and materials working together long-term. The wrong combo between framing sealants and coatings could lead to bubbling or staining down the line.

Balancing Fabrication and Finishing Costs Without Compromising Performance

Let’s break this down into bite-sized wins:

- Go mid-grade on backside coats if hidden from view—save cost without sacrificing protection.

- Streamline fabrication by pre-coating standard panel sizes before cutting custom ones.

- Use batch-finishing processes for large jobs—it reduces per-panel labor time significantly.

- Always weigh upfront savings against rework risk; cheap now might mean pricey fixes later.

Finding that sweet spot between budget control and long-term durability isn’t magic—it’s smart planning backed by material science.

Project Logistics Considerations: Packaging, Shipping Methods, and Storage Conditions

Here’s how you keep your investment safe before it ever hits the façade:

Step 1: Use foam interleaving between each coated panel during packaging to prevent abrasion marks during transit.

Step 2: Choose climate-controlled containers when shipping across humid regions—moisture buildup can ruin even top-tier coatings before install day arrives.

Step 3: Store flat in dry areas off direct concrete contact; condensation from slab floors can corrode unprotected edges fast.

Even perfect panels get wrecked by sloppy handling—logistics matter more than most folks think when dealing with delicate coating durability on high-end aluminum panels.

FAQs about Aluminum Curtain Walls

1. What makes PVDF coatings reliable for coastal Aluminum Curtain Walls?

Salt-heavy air corrodes quickly—but PVDF holds firm:

- Corrosion resistance shields alloy composition from salt spray damage.

- Maintains surface finish and tensile strength against relentless wind load requirements.

- Slow thermal expansion under harsh sunlight means panels stay true to shape year after year.

2. How do coatings keep color uniform on large panel dimensions?

It’s not just artistry—it’s chemistry at work: uniform pigment spread anchors rich tones across extended panel widths, ensuring even edge treatment and fabrication tolerances survive heat waves and cool nights without streaking or fading.

3. Why should alloy composition be checked before applying the PVDF finish?

The meeting of metal and coating isn’t casual—tensile strength matters; if an alloy flexes too easily during extrusion or welding techniques, adhesion falters over time. Picking a grade with low deformation risk safeguards long-term fire rating compliance and crisp surface finishes in unforgiving climates.

4. How does fire rating influence curtain wall safety codes?

A high fire rating is more than paperwork—it reassures every occupant inside:

- Meets performance standards tied to building codes for multi-story structures.

- Reduces insurance liabilities by enhancing structural survival during emergency heat events.

- Aligns with safety regulations while complementing the framing system design.

5. In what way can quality control during extrusion improve reliability?

Every length of aluminum tells its own manufacturing story—quality control keeps it honest: thickness checks prevent powder coating flaws; tolerance checks align sheet metal fabrication with anchoring mechanisms, while pressure plate fitment ensures drainage systems perform when storms push hard against that façade.

6. Why store PVDF-coated panels carefully before installation?

Because beauty is fragile before it’s bolted into place: protective films preserve surface finish from scratches; moisture-free storage conditions guard against corrosion creeping in early; thoughtful stacking avoids unwanted bends—all setting the stage for a smooth installation sequence that respects both material costs and warranty terms later on.