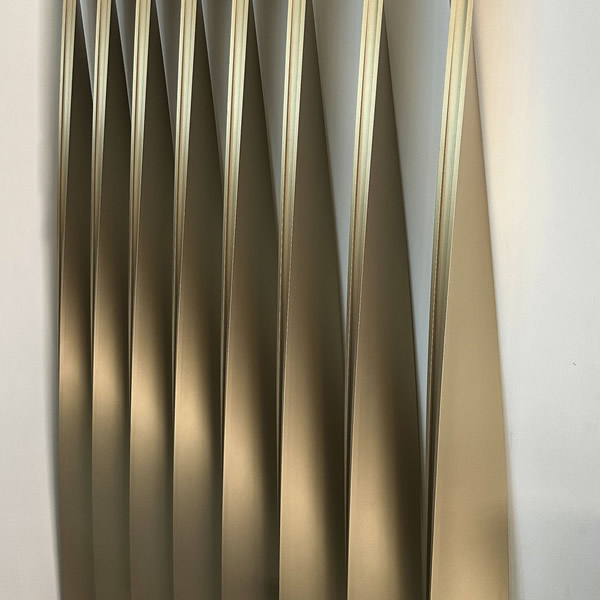

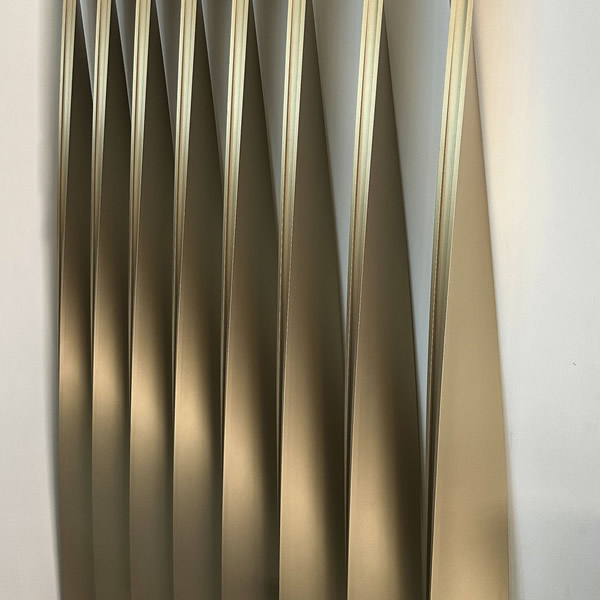

Twisted aluminum panel

Twisted Aluminum Panel Twisted aluminum panel is a specially engineered sheet made from high-grade aluminum alloys, featuring complex 3-D curvature and contorted geometries. It is widely specified in contemporary architecture and industrial design for its sculptural impact and structural efficiency. Key Material Properties • Alloy: Typically Al-Mg (5xxx series) or Al-Mn (3xxx series) for an […]

Bulk customization is available for project orders. Specifications and delivery are confirmed after design review.

Twisted Aluminum Panel

Twisted aluminum panel is a specially engineered sheet made from high-grade aluminum alloys, featuring complex 3-D curvature and contorted geometries. It is widely specified in contemporary architecture and industrial design for its sculptural impact and structural efficiency.

Key Material Properties

• Alloy: Typically Al-Mg (5xxx series) or Al-Mn (3xxx series) for an optimal strength-to-weight ratio

• Lightweight: Up to 60 % lighter than comparable steel cladding

• High strength: Yield strength ≥ 180 MPa after forming

• Corrosion-resistant: Natural aluminum oxide layer plus optional PVDF or anodized finish for marine-grade durability

Manufacturing Process

1. CNC precision cutting of raw coil or plate

2. 3-D forming via cold or hot bending to achieve the desired twist radius and double curvature

3. Surface treatment: anodizing, powder-coating or PVDF coating for colorfastness and UV resistance

Typical Applications

• Architectural curtain walls and façades

• Museums and exhibition pavilions

• Retail hubs and mixed-use complexes

The dynamic twist gives buildings a fluid, kinetic appearance while maintaining structural integrity and low maintenance requirements.

Design Features

- Enhanced Thermal Break: 42mm PA66 GF25 thermal break for superior insulation performance

- Triple Glazing Option: 4mm + 16A + 4mm + 16A + 4mm LOW-E configuration

- Pressure Equalized Design: Dual cavity drainage for weather protection

- Structural Reinforcement: 6061-T6 aluminum alloy for high wind load performance

- Custom Finishes: PVDF coating with long-term color retention

Installation Advantages

Factory Quality Control

Units pre-assembled and tested for air, water, and wind performance.

Rapid Installation

Faster installation reduces on-site labor and downtime.

Minimal Disruption

Reduced construction time with clean on-site assembly.

Precision Engineering

Tight tolerance manufacturing ensures consistent alignment.

Project Highlights

- Energy efficiency targets for high-rise towers

- Large panel sizes for reduced joint visibility

- Custom finishes to match facade design intent

Service Scope

- Engineering consultation

- Fabrication and QA

- Export logistics

- On-site installation support

Bulk Inquiry Form

Provide project details and requirements for Twisted aluminum panel. Our engineering team will respond with recommendations.