Perforated Aluminum Acoustic Baffle with Rockwool Core and Stainless Steel Fixings

The Challenge & Solution

Tame Noise in Style with Our Durable Acoustic Baffles

Looking for a high-performance sound-absorbing solution that combines durability with modern design? Our Perforated Aluminum Acoustic Baffles are engineered for superior noise control in demanding environments. Ideal for open-plan offices, industrial facilities, bustling restaurants, and commercial atriums, these baffles effectively reduce reverberation and background noise, creating a more comfortable and productive acoustic environment.

Crafted with a perforated aluminum shell and a dense Rockwool core, all supported by a robust stainless steel fixing system, these baffles offer an unbeatable blend of acoustic efficiency, long-lasting durability, and sleek aesthetics.

Key Features & Benefits

-

✔️ Superior Sound Absorption

-

The perforated aluminum face allows sound waves to penetrate easily, where they are trapped and dissipated by the high-density Rockwool core. This combination effectively soaks up excess noise, slashing echo and improving speech clarity.

-

-

✔️ Robust & Long-Lasting Construction

-

Built to last. The aluminum shell is corrosion-resistant and scratch-resistant. When combined with our stainless steel fixings and brackets, this baffle system withstands the test of time, even in humid or demanding environments, ensuring your investment is protected.

-

-

✔️ Exceptional Fire Safety (A1 Non-Combustible)

-

Safety first. The Stone Wool (Rockwool) core is classified as Euroclass A1 / Class A – meaning it’s completely non-combustible. It provides superior fire resistance, helping to meet strict building safety codes and protect occupants.

-

-

✔️ Sleek, Modern Aesthetic

-

Beyond their acoustic function, these baffles add a clean, architectural look to any space. Available in a range of powder-coat finishes, they can be seamlessly integrated into any interior design scheme or left as a statement feature.

-

-

✔️ Easy & Secure Installation

-

Simplify your project with our designed stainless steel facade fixing system. The fixings provide a secure and reliable method for hanging the baffles, ensuring a safe installation from ceilings or walls with minimal visual clutter.

-

Technical Specifications & Attributes

Attribute Description Product Type Hanging Acoustic Baffle / Sound Absorbing Baffle Face Material Perforated Aluminum Sheet (Powder-coated finish) Core Material High-Density Rockwool (Stone Wool) Fixing System Stainless Steel (S.S.) Fixings, Brackets, and Hardware Primary Function Noise Reduction, Reverberation Control, Echo Elimination Acoustic Performance High NRC (Noise Reduction Coefficient) – typically up to 0.95-1.00+ Fire Rating Euroclass A1 / Class A (ASTM E84) – Non-combustible Applications Offices, Schools, Restaurants, Hotels, Industrial Facilities, Gyms, Lobbies Installation Ceiling or Wall Mount (via suspension cables or direct fixings) Customization Available in various sizes, perforation patterns, and colors

-

Architectural Vision

The architectural intent required a facade that could disappear into the skyline while maximizing internal views. Our engineering team developed a custom bespoke extrusion profile that minimized the visible sightlines found in traditional curtain wall systems.

Project Data

Used Technologies

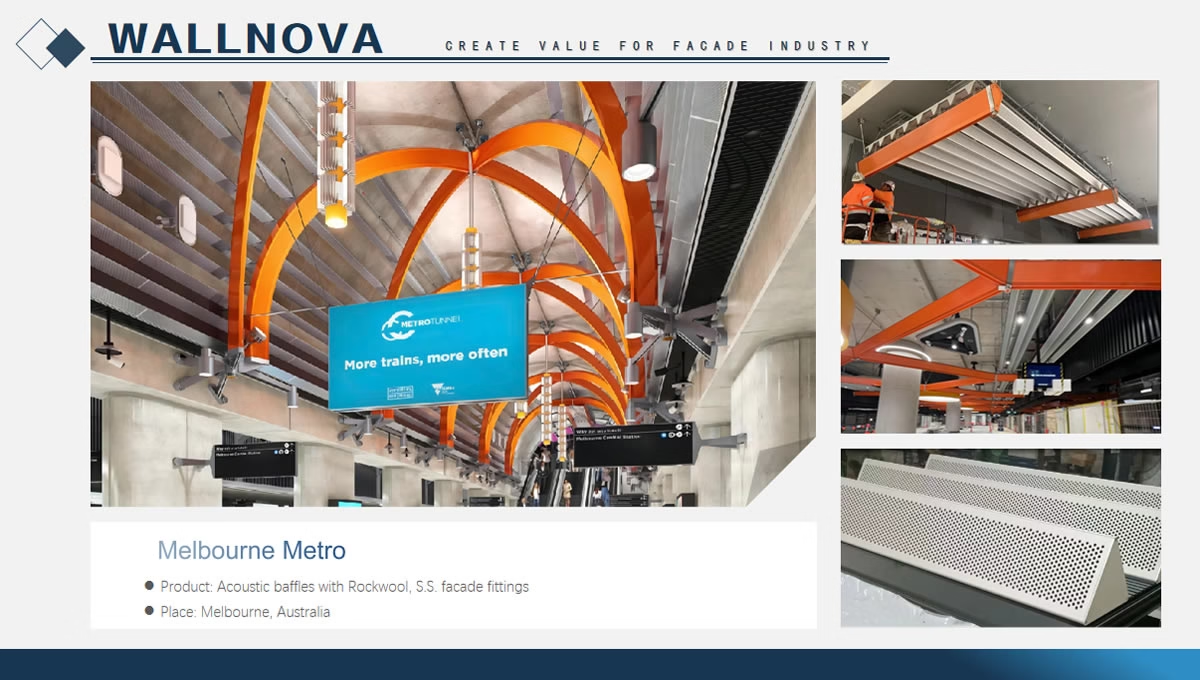

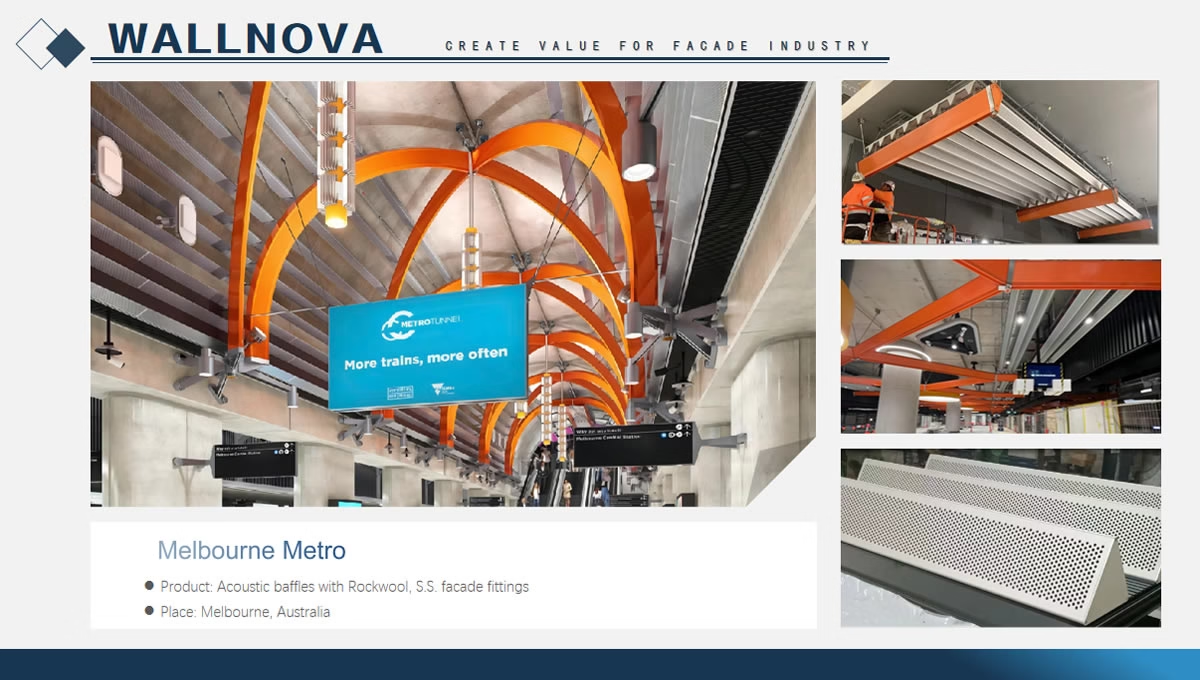

Field Report Gallery

Click on any image to view high-resolution details of the installation process and finished facade.