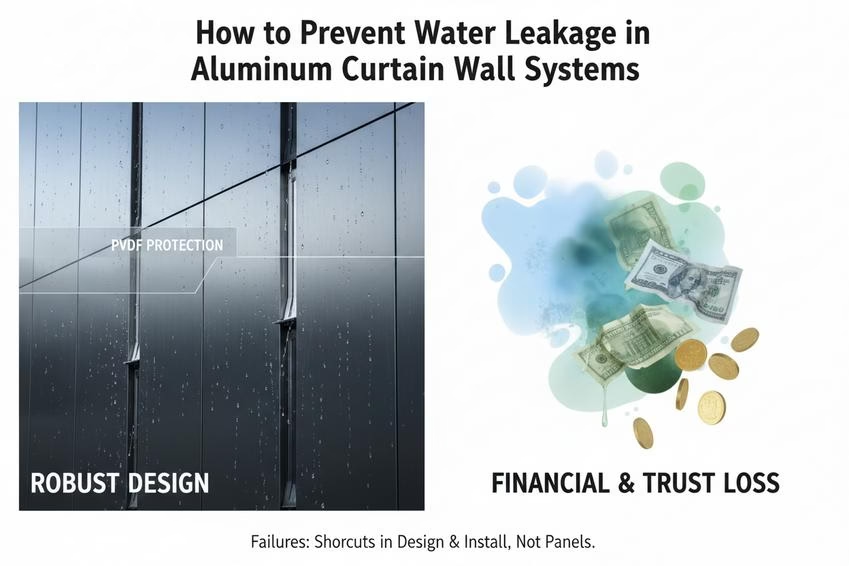

When storms hit, weak Aluminum Curtain Wall designs leak cash and trust—choose smart specs and PVDF panels to keep rain, and regrets, out.

Rain doesn’t knock—it barges in. If your building’s Aluminum Curtain Wall isn’t holding up its end of the bargain, water will find every crack, corner, and lazy seal like a nosy neighbor with too much time. And when it does? You’re not just fixing leaks—you’re fielding angry tenants, footing five-figure maintenance bills, and explaining to stakeholders why your “state-of-the-art” facade is crying during storms.

“Most failures we see aren’t about the panels,” says Jenna Ruiz, Senior Systems Engineer at Wallnova (Q1 2024 Design Report). “It’s about the shortcuts taken during design or install—drainage ignored or cheap coatings that don’t last a season.” Oof.

This isn’t just about getting it right—it’s about not paying for it twice. So buckle in as we unpack how smarter specs, better materials (hello PVDF), and no-nonsense engineering can save you from costly surprises—and soggy conference rooms.

Why Aluminum Curtain Wall Systems Leak In The First Place

When your high-rise starts to drip, it’s often more than just bad luck—it’s usually a design or material flaw. Let’s break down what’s really going on behind those sleek glass and aluminum facades.

Common causes of water infiltration in high-rise buildings

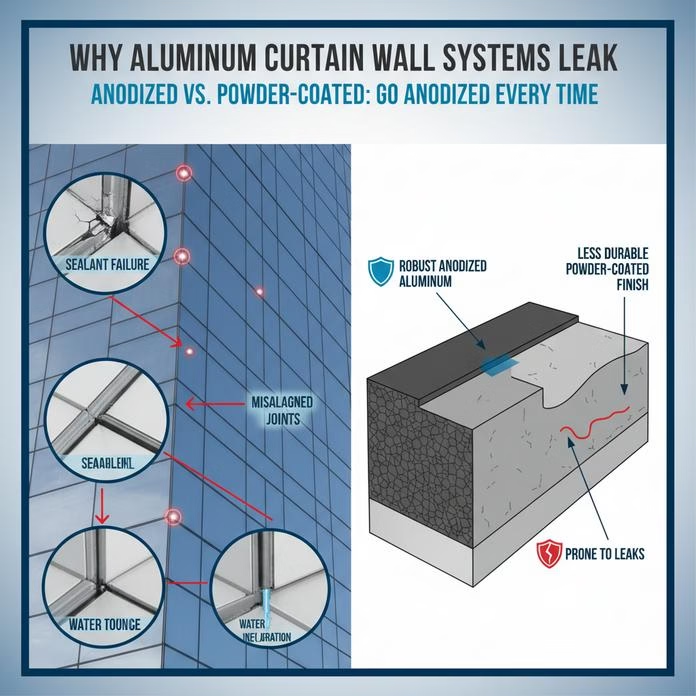

• Poorly applied sealant failure around window perimeters lets moisture sneak in.

• Misaligned joints between panels can create tiny but persistent leak paths.

• Rushed installations often skip proper flashing, leaving the building envelope exposed to wind-driven rain.

Design oversights like inadequate drainage channels or lack of pressure-equalized chambers are notorious culprits too. Once water finds a weakness, gravity and capillary action do the rest—fast.

The impact of aluminum alloy selection on leakage

Multiple short segments explain why your choice of aluminum alloy matters more than you think:

– Alloys with low corrosion resistance, like the common but weaker 3003 series, degrade faster under coastal or industrial exposure.

– High thermal expansion in certain alloys causes micro-gaps at panel seams when temperatures swing wildly between seasons.

– Inferior fabrication tolerances can weaken overall structural integrity, making joints vulnerable over time.

Choosing a high-performance alloy like the 6063-T5 doesn’t just improve strength—it also helps keep moisture out where it belongs.

Anodized aluminum vs. powder-coated aluminum: Which is more leak-resistant?

Here’s how these two finishes stack up side by side:

| Finish Type | Corrosion Protection | Sealant Adhesion | Durability Over Time |

|---|---|---|---|

| Anodized Aluminum | Excellent | Strong | Long-lasting |

| Powder-Coated Aluminum | Moderate | Variable | May chalk or peel |

Anodizing creates a hard oxide layer that bonds directly with the metal, enhancing both appearance and waterproofing potential. Powder coating looks great initially but may crack under UV exposure, compromising its ability to resist leaks long-term.

So if you’re serious about keeping your curtain wall dry? Go anodized every time for better lasting results across all climates—even those that throw everything from salt spray to acid rain at your facade.

Design Flaws That Compromise Aluminum Curtain Wall Waterproofing

Waterproofing failures often trace back to design missteps hiding in plain sight. Let’s break down what really compromises your aluminum curtain wall system.

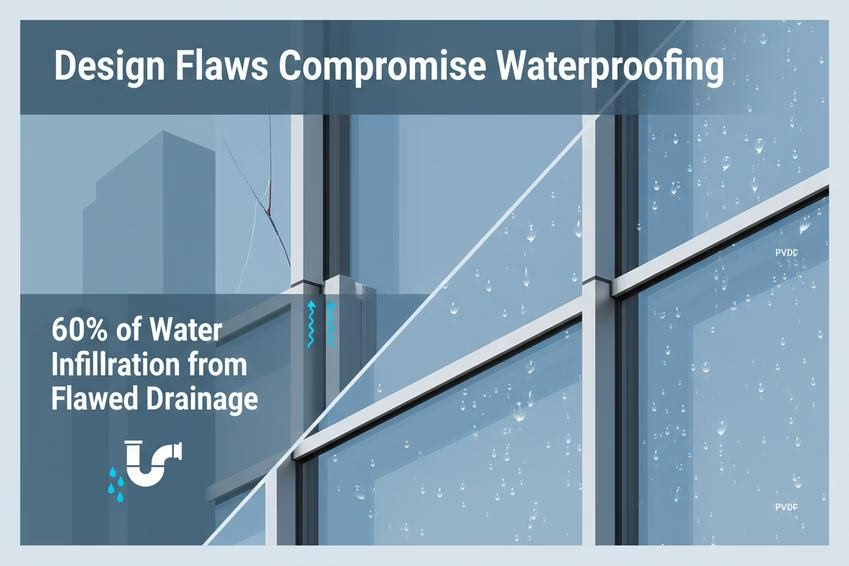

Key design elements in high-rise building facades

- Window alignment: Poorly placed windows interrupt vertical drainage paths, letting water sneak into the building envelope.

- Joint configuration: Gaps that lack pressure-equalized chambers or flexible sealants weaken the curtain wall system’s defense.

- Panel integration: Misaligned or mismatched panels can lead to wind-driven rain bypassing seals and soaking insulation.

When these elements don’t work together, you’re not just risking leaks—you’re gambling with your building’s long-term structural integrity, especially under intense wind load conditions common at height.

Choosing the right coating: PVDF fluorocarbon vs. polyester powder coat

Coating choices aren’t just about color—they’re about survival.

• PVDF coating offers elite durability, resisting UV rays and acid rain while maintaining excellent color retention over decades.

• In contrast, a basic polyester powder finish might save money upfront but fades fast and struggles against harsh weather swings.

• For projects expecting long-term exposure, PVDF is the no-brainer—especially when paired with advanced primers for better adhesion on aluminum surfaces.

Wallnova recommends PVDF for all exterior-facing systems where waterproofing isn’t negotiable—it’s a small premium for peace of mind.

Importance of surface treatment in preventing water ingress

An untreated panel is like an open door for moisture—don’t give it an invitation.

Short segment 1: Surface prep matters more than most folks think; it determines how well coatings stick and how thoroughly sealants bond to the panel edge.

Short segment 2: Treatments like anodizing, or adding a hydrophobic layer, boost resistance to corrosion and prevent micro-cracks from turning into leak paths over time.

Short segment 3: A properly treated panel doesn’t just look good—it actively repels moisture, reducing maintenance headaches by half over its lifecycle.

The role of improper drainage design in aluminum curtain walls

A report by BSRIA released March 2024 noted that “Over 60% of water infiltration cases stemmed from flawed drainage detailing within facade assemblies.”

Here’s where things typically go sideways:

- Missing or undersized weep holes

- Blocked internal cavities that trap condensation

- Lack of proper slope on horizontal mullions

- No pressure-equalization chamber between outer skin and backup wall

- Inadequate flashing details around spandrel zones

Each mistake compounds the next until your sleek modern façade becomes a sponge during every storm. Smart water management isn’t optional—it’s survival engineering for any modern-day high-rise using an aluminum curtain wall system.

4 Critical Nodes That Decide Curtain Wall Waterproof Performance

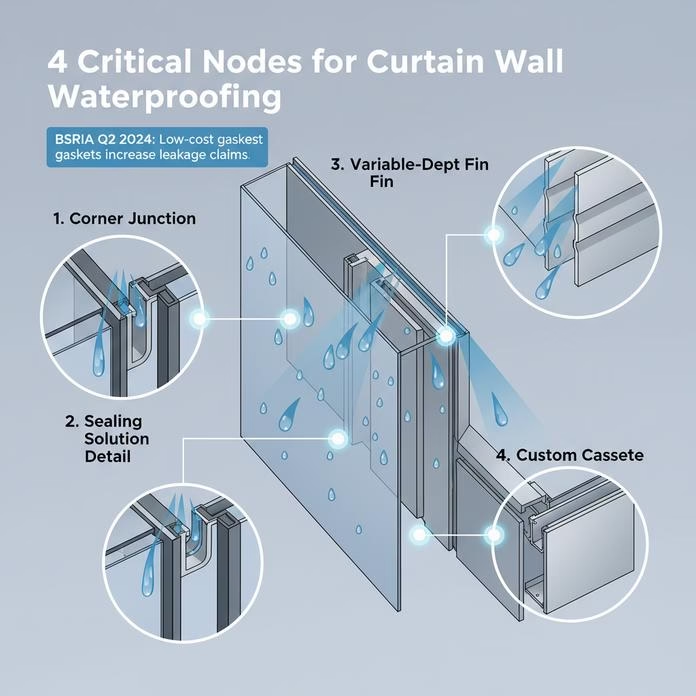

Keeping water out isn’t just about slapping on sealant. These four make-or-break details decide how well an aluminum curtain wall holds up when the weather gets wild.

Corner junctions: How they can lead to leaks

- Miter joints at corners are tricky—if they’re off even slightly, gaps appear.

- Weak corner seals often degrade faster due to thermal stress.

- Water finds its way through failed junction points, especially where panels meet at angles.

- Poorly applied or aged-out sealant is one of the most common causes of leaks here.

A single bad corner can compromise the entire waterproofing game. Always double-check those angles and reapply sealant before it’s too late.

Understanding the sealing solutions for aluminum profiles

Airtight isn’t enough—it has to be watertight. And that comes down to smart sealing choices:

• Silicone-based solutions offer flexibility and long-term adhesion, ideal for dynamic joints.

• EPDM gaskets, resistant to UV and ozone, are popular for their durability across climates.

• Pressure-equalized systems use internal chambers and drainage paths alongside well-designed glazing beads and pressure plates.

According to a recent report by BSRIA in Q2 of 2024, “over-reliance on low-cost gaskets has led to a measurable uptick in post-installation leakage claims across commercial facades.” Choose wisely.

Assessing the performance of variable depth aluminum fins

Let’s break this down into key performance checks:

| Fin Depth Variation | Drainage Efficiency | Wind Load Resistance | Thermal Expansion Control |

|---|---|---|---|

| Uniform Fins | Moderate | High | Low |

| Variable Fins | High | Moderate | Medium |

| Deep-set Fins | Very High | Low | High |

Variable-depth fins aren’t just pretty—they help manage rainwater runoff if placed right. But misalign them? You’ll get water pooling instead of draining. Always balance design with function when integrating these into your aluminum facade system.

Custom size aluminum cassettes: Benefits for waterproof integrity

Custom-fit always beats off-the-shelf when it comes to keeping moisture out:

- Tailored dimensions reduce reliance on excessive sealants at panel edges.

- Prefabricated cassettes allow tighter control over factory-installed seals, ensuring better seal continuity.

- On-site installation becomes more accurate due to minimized cutting, reducing human error that leads to leaks.

And because these units are part of larger modular designs like unitized systems, your quality control ramps up significantly—especially crucial for large-scale glass-and-metal facades like an aluminum curtain wall system.

Done right, custom cassettes not only improve aesthetics but also give your building envelope serious staying power against wind-driven rain.

How Improper Installation Triggers Curtain Wall Water Leakage

Don’t let poor installation wreck your building’s vibe—here’s how it can mess with your curtain wall and what to do about it.

Consequences of improper installation on architectural wall panel systems

• Poorly installed architectural panels often lead to misaligned joints that allow moisture intrusion, especially around corners and seams.

• Gaps in the system compromise the building envelope, letting water seep in behind the panels, which causes hidden rot and mold.

• Over time, these flaws snowball into major water damage, weakening the wall’s structural integrity and driving up long-term repair costs.

Essential practices for installing marine grade aluminum cladding

- Always double-check material specifications before cutting or mounting—marine-grade means nothing if it’s scratched or dented during handling.

- Use high-quality sealants with proven corrosion resistance, especially where panels meet windows or structural breaks.

- Install proper drainage paths behind the cladding; without them, trapped water can degrade even premium marine grade aluminum over time.

How to avoid leaks during exterior wall cladding projects

Long story short: don’t wing it with waterproofing.

Every joint needs solid sealant application, especially around penetrations like vents and anchors. Flashings must be layered right—the top always overlaps the bottom—to keep water flowing out, not in. And never skip a test run: hose down a section post-installation to check your work before calling it done.

The ripple effects of moisture intrusion on curtain walls

Water sneaks in through just one bad seam—and then? It spreads fast.

You’ll start seeing bubbling paint, warped insulation, maybe even rust on framing components behind the surface of your aluminum curtain wall system. That’s not just ugly; it compromises energy efficiency and invites pests too.

Common sealing mistakes that lead to leakage issues

• Using incompatible sealants that break down under UV exposure or heat cycles

• Skipping primer when applying sealants on oily surfaces like some anodized panels

• Applying too little product at joints or corners where movement is expected

Each slip increases chances of leaks—and once they start, reversing damage is no quick fix.

What happens when drainage systems are overlooked?

Think of drainage as insurance you install once but rely on forever.

Without dedicated weep holes or back-drainage planes, any rainwater that gets past the outer layer stays trapped inside your cladding system—turning into a breeding ground for mold and corrosion beneath your shiny aluminum façade.

Fastening methods that prevent structural issues

Grouped by function:

— For stability: Use stainless steel anchors rated specifically for exterior use; avoid mixing metals that cause galvanic reactions near marine environments.

— For flexibility: Incorporate sliding clips or brackets where thermal expansion is expected across wide spans of an aluminum curtain wall setup.

— For longevity: Space fasteners evenly based on wind load calculations—not just aesthetics—to prevent panel flutter and fatigue cracks over time.

Why quality control checks matter during installation

A solid QC process saves you from nasty surprises later:

- Verifying alignment prevents visible warping under sunlight glare.

- Checking every joint ensures consistent pressure seals across all edges.

- Confirming correct torque settings on fasteners avoids premature loosening during storms.

- Inspecting flashing overlaps guarantees uninterrupted moisture shedding performance.

Even small misses add up fast when you’re working with precision-built materials like modern aluminum curtain walls—even more so if you’re near coastal zones where salt spray accelerates wear-and-tear.

By sticking to best practices from day one, you’ll dodge most of those common pitfalls—and keep your building dry while looking sharp year-round.

Building Long-Term Value With Leak-Free Curtain Walls

A leak-free curtain wall isn’t just about staying dry—it’s about building smarter, greener, and more cost-effective from the ground up.

Sustainable building construction initiatives with aluminum systems

Aluminum-based systems are changing the game for sustainable design. Here’s how they’re making buildings leaner, cleaner, and tougher:

- ♻️ Recyclability: Aluminum is 100% recyclable without quality loss. That means lower embodied energy and less landfill waste.

- 🌞 Energy efficiency: High-performance framing reduces thermal bridging, improving insulation and slashing HVAC loads.

- 🛠️ Durability & lifecycle performance: Strong resistance to corrosion ensures longer life cycles—less frequent replacements equal fewer resources consumed.

Multiple short descriptive segments: Aluminum curtain wall components often integrate thermal breaks and low-E glass to boost energy efficiency. These features reduce heating/cooling demands—a win for both your wallet and the planet. On top of that, aluminum’s lightweight nature cuts down on structural load requirements during construction.

Grouped bullet structure: Environmental impact reductions

- Lower carbon footprint due to minimal maintenance needs

- Fewer repairs mean fewer emissions from manufacturing replacement parts

Improved construction practices

- Prefabrication potential reduces onsite waste

- Clean installation methods align with green certification standards

Lifecycle assessment findings According to a 2024 report by the International Green Construction Council (IGCC), buildings using aluminum systems showed a 27% reduction in overall environmental impact over 30 years compared to traditional façade materials.

By blending durability with sustainability, aluminum curtain walls offer not just style—but long-term substance.

Cost-benefit analysis: Investing in leak-proof aluminum curtain walls

Going leak-proof may sound pricey upfront—but let’s break it down:

- 💸 Initial investment is higher than conventional façades.

- 🔧 But maintenance savings stack up fast—no more costly water damage repairs.

- 🏢 Plus, property value tends to rise when waterproofing is built-in rather than retrofitted.

Natural combination of structures: Leak-proofing an aluminum curtain wall system isn’t just about slapping on seals—it’s about integrating smart waterproofing solutions, pressure-equalized joints, and drainage planes that work together like a well-oiled machine.

Here’s what you get out of it: • Lower lifecycle costs over 25+ years

• Reduced insurance risk due to minimized water infiltration

• Boosted tenant satisfaction thanks to better indoor air quality

“Recent data from BOMA’s 2024 Facility Performance Index shows buildings with high-integrity façades report 33% fewer annual repair incidents.” This kind of stat shows why waterproofing isn’t optional anymore—it’s strategy.

Grouped bullet structure: Return on investment (ROI) drivers

- Long-term durability protects against climate-related wear

- Reduced operational disruptions during storms or seasonal shifts

Financial analysis insights

| Feature | Traditional Façade | Leak-Proof Aluminum Wall |

|---|---|---|

| Avg. Yearly Maintenance ($/sqft) | $2.10 | $0.85 |

| Expected Lifespan (years) | 20 | 35 |

| Insurance Premium Impact | Neutral | -12% |

When you add it all up? A leak-free aluminum curtain wall doesn’t just pay for itself—it pays forward into every square foot of your future.

FAQs about Aluminum Curtain Wall

1. Why do aluminum curtain wall systems sometimes develop leaks?

- Poor sealing in corner joints or gaps between custom size aluminum cassettes often allows rain to creep inside.

- Inconsistent PVDF fluorocarbon paint coating thickness can let moisture penetrate into the substrate, eroding protective layers over time.

- When installers skip applying weather resistant epoxy primer beneath metallic silver aluminum finish panels, water retention quickly accelerates corrosion.

Summary: Leakage isn’t just a symptom—it hints at early neglect in material protection and fitting precision within architectural wall panel systems.

2. How does alloy selection influence waterproof durability on large facades?

Choosing marine grade aluminum cladding ensures smoother surface layering that resists salt-laden air better than an unprotected aluminum alloy 3003 series sheet would under constant humidity exposure. The choice becomes critical for high-rise building facades near coastal zones where wind-driven rain meets aggressive air salts.

| Alloy Type | Corrosion Resistance | Recommended Application |

|---|---|---|

| 3003 Series Aluminum | Medium | Interior walls, mild climates |

| Marine Grade Cladding | Excellent | Exterior coastal projects |

3. Which coatings best prevent leakage and fading across decades of exposure?

Short description + bullet logic—each coat serves differently:

• PVDF fluorocarbon paint coating: Long-term defense with radiant RAL color code selection; ideal for commercial building curtain walls exposed to UV-rich climates.

• Polyester powder coat finish: Cost-effective but demands recoating sooner on building renovation cladding projects.

• Anti-graffiti protective coating: Shields decorative matte black powder coated sheets from stains without altering texture or gloss levels.

Quick insight: Adding self-cleaning nano titanium dioxide enhances sunlight-based dirt decomposition—a quiet ally against dullness and grime buildup.

4. Can improper installation create immediate infiltration points?

Yes—especially when variable depth aluminum fins misalign or fasteners distort thermally expanded joints during construction sequencing:

1️⃣ A skewed bracket can tear gaskets meant to hug anodized aluminum sheet metal edges tightly;

2️⃣ Misread dimensions may leave mill finish aluminum panels protruding slightly, letting capillary action pull water inward after the first storm of a new construction facade project.

5. Are anodized surfaces more reliable than powder-coated ones against ocean spray damage?

The clear oxide barrier formed on anodized panels protects them like invisible armor—impermeable yet elegant under a bronze anodized aluminum tone or brushed aluminum surface finish texture line patterning typical in ventilated facade construction projects near coasts.

Meanwhile, powder-coated finishes please designers via broader color variety—from metallic silver sheen to deep charcoal—but demand more routine care once fine cracks appear due to sun expansion cycles.

6. What design oversights most commonly lead to chronic leakage issues?

Grouped bullets help visualize fault lines within large-scale commercial building developments:

◎ Neglected drainage channels behind perforated or corrugated aluminum profile system sections trap hidden pools of runoff water;

◎ Overconfidence in sealants instead of allowing calculated weep paths disrupts evaporation balance;

◎ Underestimating shrinkage differences among 4mm thick aluminum panels joined with longer 3000mm long aluminum profiles stresses connectors beyond tolerance limits during seasonal temperature swings.

Small misjudgments here grow into expensive repairs later—confirming how detail defines longevity in every architectural design implementation project chasing sustainable building construction initiatives.