I. Introduction

Application Value & Importance of Aluminum Panel Curtain Walls

- Aesthetic & Functional Dominance: Aluminum panels offer sleek, modern facades with high durability and corrosion resistance, critical for landmark buildings and high-rise structures.

- Versatility in Design: Adaptable to curves, perforations, and custom finishes (e.g., PVDF coatings, anodized surfaces).

- Durabilité: Recyclable material with low embodied energy, aligning with LEED v4 and BREEAM standards.

Role of Regular Cleaning & Maintenance in Lifespan Extension

- Corrosion Prevention: Urban pollutants (acid rain, salt spray) degrade aluminum’s protective oxide layer over time.

- Aesthetic Preservation: Dirt accumulation dulls surfaces, while biofouling (algae, lichen) causes permanent staining.

- Structural Integrity: Clogged drainage systems lead to water infiltration, risking substrate rot and fastener corrosion.

Consequences of Improper Maintenance

- Surface Damage: Abrasive cleaners scratch anodized/painted finishes, exposing bare metal to oxidation.

- Coating Delamination: High-pressure washing (>1500 psi) can peel PVDF coatings.

- Safety Hazards: Neglected panels may detach due to corrosion-weakened fasteners.

II. Maintenance Framework Overview

This guide outlines a 4-tier strategy:

- Routine Inspections: Quarterly visual checks for cracks, loose panels, and sealant failure.

- Preventive Cleaning: Semi-annual washing with pH-neutral detergents.

- Corrective Actions: Immediate repair of damaged panels/fasteners.

- Sustainability Integration: Use of recycled water and eco-friendly cleaners.

III. Technical Specifications & Compliance

Adherence to ASTM D7802 (cleaning aluminum finishes), ISO 12944-6 (corrosion protection), and local building codes ensures long-term performance. For historic structures, consult preservation boards to avoid damaging patina or heritage finishes.

IV. Sources of Contamination on Aluminum Panel Curtain Walls

A. Natural Environmental Factors

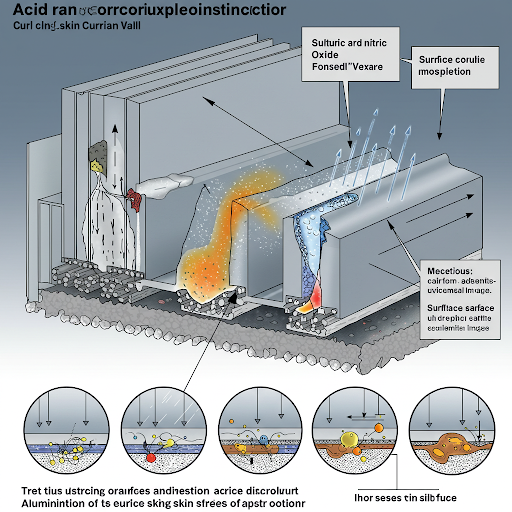

Acid Rain Erosion

- Chemical Mechanism: Sulfur dioxide (SO₂) and nitrogen oxides (NOₓ) from industrial emissions react with atmospheric moisture to form sulfuric (H₂SO₄) and nitric (HNO₃) acids.

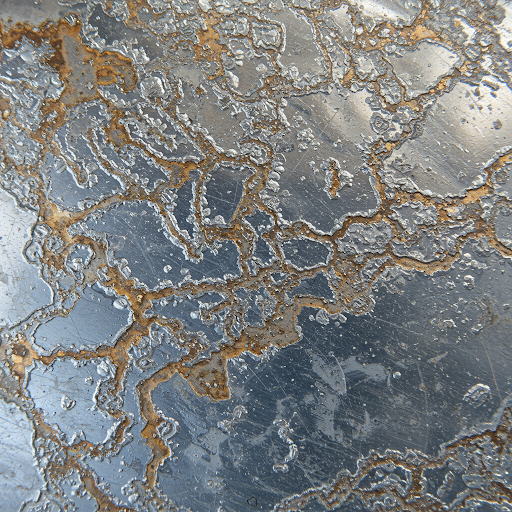

- Material Impact: pH <5.6 rainfall etches aluminum surfaces, dissolving the protective oxide layer (Al₂O₃) and promoting intergranular corrosion.

- Visible Effects: Matte-finish panels develop “frosted” textures; anodized surfaces lose luster.

Dust & Sand Accumulation

- Abrasive Damage: Quartz particles in windblown dust (Mohs hardness 7) scratch PVDF coatings (≥2H pencil hardness) over time.

- Microclimate Effects: Dust layers trap moisture, accelerating galvanic corrosion between aluminum and dissimilar metals (e.g., steel fasteners).

UV Degradation & Thermal Cycling

- Photo-Oxidation: UV-B radiation (290-320nm) cleaves polymer chains in fluorocarbon coatings, reducing gloss retention and color fastness.

- Thermal Shock: Diurnal temperature swings (e.g., -20°C to +60°C) cause coating microcracks, particularly in dark-colored panels absorbing higher IR energy.

B. Anthropogenic Pollution Factors

Construction Residues

- Cementitious Contamination: Portland cement hydration byproducts (Ca(OH)₂) raise local pH >12, saponifying organic coatings.

- Paint Overspray: Solvent-based aerosols soften PVDF surfaces, enabling adhesion of foreign particles.

- Sealant Outgassing: Silicone sealants release acetic acid during cure, attacking anodized layers.

Traffic & Industrial Emissions

- Particulate Matter (PM2.5/PM10): Diesel exhaust contains polycyclic aromatic hydrocarbons (PAHs) that adhere to hydrophobic coatings via van der Waals forces.

- Heavy Metal Deposition: Lead (exhaust) and copper (brake pads) ions catalyze redox reactions on aluminum surfaces.

Human-Induced Staining

- Sebaceous Oils: Fingerprints contain triglycerides and free fatty acids that degrade acrylic clearcoats.

- Graffiti: Aerosol paints containing xylene/toluene dissolve polyester resin binders in powder-coated panels.

- Biodeterioration: Bird guano uric acid (pH 3.5-4.5) pits aluminum substrates, while spider webs trap corrosive particulates.

C. Synergistic Degradation Pathways

- Acid Rain + Dust: Acidified mud acts as electrolyte, bridging aluminum surfaces to carbon steel brackets.

- UV + Traffic Pollution: PAHs under UV irradiation generate singlet oxygen (¹O₂), oxidizing organic coatings.

- Temperature Cycling + Construction Residues: Thermal expansion stresses combined with alkaline attack exacerbate coating delamination.

V. Cleaning Methods for Aluminum Panel Curtain Walls

A. Routine Maintenance Protocols

Dry Dust Removal

- Tools: Use microfiber dusters or lambswool wipers (particle size <10μm) to avoid micro-scratching.

- Frequency: Bi-weekly in urban zones (PM2.5 >35 μg/m³); monthly in rural areas.

Neutral pH Washing

- Solution Preparation: Dilute 5% ammonium bicarbonate (pH 8.3) with deionized water to prevent mineral streaking.

- Application: Pre-soak panels for 3-5 minutes to loosen organic deposits; wipe with non-abrasive cellulose sponges.

B. Intensive Stain Treatment

Oil & Grease Removal

- Solvent Selection: Use terpene-based cleaners (d-limonene) for hydrocarbon stains, avoiding chlorinated solvents that attack PVDF.

- Emulsification Technique: Apply surfactant solution (0.5% sodium dodecyl sulfate) via low-pressure sprayer, dwell time 10-15 mins.

Water Spot Dissolution

- Chemical Action: Apply 2% citric acid solution to chelates calcium carbonate deposits; rinse with EDTA-chelated water to prevent re-deposition.

Cementitious Residue Removal

- pH-Controlled Attack: Use buffered phosphoric acid (pH 2.5) gel to avoid over-etching anodized layers.

- Neutralization: Rinse with sodium bicarbonate solution (pH 9.5) post-treatment.

C. Specialized Cleaning Techniques

High-Pressure Water Jetting

- Parameter Control: Maintain 80-120 bar pressure at 40cm standoff distance; use fan-shaped nozzles (40° spray angle) to prevent surface fatigue.

- Water Quality: TDS <100 ppm to minimize salt crystallization post-drying.

Abrasive Blasting

- Media Selection: Use calcium carbonate pellets (Mohs 3) or walnut shells for matte finishes; avoid aluminum oxide (Mohs 9) on glossy panels.

- Vacuum Recovery: Deploy HEPA-filtered systems to capture spent media and prevent secondary contamination.

Electrochemical Cleaning

- Anodic Stripping: Apply 5V DC in sodium hydroxide electrolyte (pH 12.5) to remove corrosion products from welded seams.

D. High-Rise Access Methodologies

Suspended Scaffolding (Swing Stage)

- Stability Control: Maintain <0.5m sway under 20m/s wind loads; use centrifugal brakes for descent control.

- Fall Protection: Implement dual lanyard attachment points with shock absorbers.

Rope Access Techniques

- IRATA Standards: Use twin ropes with 12kN minimum breaking strength; conduct daily rope inspection via capstan testing.

Unmanned Aerial Systems (UAS)

- Payload Optimization: Deploy hexacopter platforms with 15L tank capacity for surfactant application.

- Regulatory Compliance: Adhere to EASA U-Space regulations for beyond visual line of sight (BVLOS) operations.

E. Post-Cleaning Validation

- Surface Energy Testing: Use goniometry to confirm contact angle >90° (hydrophobic restoration).

- Gloss Retention Measurement: Compare pre/post-cleaning 60° gloss values using ISO 2813 methodology.

- Coating Integrity Assessment: Perform cross-hatch adhesion testing (ASTM D3359) to ensure no delamination.

VI. Maintenance Techniques for Aluminum Panel Curtain Walls

A. Anti-Corrosion Management

Coating Inspection Protocols

- Frequency: Biannual inspection in marine environments (C4-C5 ISO 12944); annual in moderate climates.

- NDT Methods: Use eddy current testing (ECT) for anodized layers >20μm; Fourier-transform infrared spectroscopy (FTIR) to assess PVDF degradation.

Corrosion Mitigation Strategies

- Galvanic Coupling: Install zinc anodes at connection points to protect aluminum from electrolytic corrosion.

- Nanocoating Restoration: Apply silica-zirconium hybrid coatings via sol-gel process for enhanced barrier properties.

B. Sealant Integrity Preservation

Failure Mode Analysis

- UV Degradation: Monitor for chalking (ASTM D4214) and color change (ΔE >1.5 in CIELAB).

- Thermal Cycling: Check for cohesive failure in joints experiencing >50°C temperature swings.

Replacement Procedures

- Joint Preparation: Use diamond-blade saws for precise sealant removal; abrasive blasting with 80-grit alumina for contaminated substrates.

- Primer Application: Apply silane-based primers to promote adhesion on galvanized steel substrates.

C. Fastener & Structural Assessment

Bolt Inspection

- Acoustic Emission Testing: Detect stress corrosion cracking in stainless steel fasteners (>A2-70 grade).

- Torque Audit: Verify clamp load using ultrasonic bolt elongation measurement (UBEM) technology.

Connection Retrofit

- Blind Fastening Systems: Install Huck bolts for inaccessible joints; use lockwire on threaded rods in high-vibration zones.

D. Surface Protection Strategies

Abrasion Prevention

- Cleaning Tool Specification: Use ultra-high molecular weight polyethylene (UHMWPE) squeegees (Shore D 60 hardness).

- Robotic Inspection: Deploy crawler drones with 3D laser scanning to detect micro-scratches <0.1mm depth.

Sacrificial Coatings

- Self-Healing Polymers: Apply polyurea coatings with microencapsulated corrosion inhibitors.

- Ceramic Pro PPF: Install thermoplastic polyurethane films (TPU) with nano-ceramic additives for IR reflection.

E. Long-Term Performance Monitoring

Condition Assessment Matrix

| Parameter | Threshold Value | Intervention Level |

|---|---|---|

| Coating Adhesion | <4B (ASTM D3359) | Immediate Repair |

| Sealant Hardness | >50 Shore A | Replace |

| Fastener Elongation | >0.5% | Retighten |

Digital Twin Integration

- IoT Sensors: Deploy capacitive moisture sensors in critical joints; monitor real-time strain via fiber optic Bragg gratings.

- Predictive Modeling: Use finite element analysis (FEA) to simulate 20-year fatigue cycles under local wind load spectra.

VII. Recommended Cleaning and Maintenance Frequency for Aluminum Panel Curtain Walls

A. Standard Environmental Conditions (Commercial Buildings)

Semi-Annual Deep Cleaning

- Objective: Remove atmospheric pollutants, biofilm growth, and mild surface corrosion.

- Methodology:

- Use neutral pH cleaners (pH 6-8) with surfactants for hydrophobic coatings.

- Apply low-pressure (<1500 psi) washing for anodized surfaces.

- SEO Keyword Integration: “aluminum curtain wall cleaning schedule commercial buildings”

Annual Comprehensive Inspection

- Scope:

- Visual assessment of 10% sample area using 20x jeweler’s loupe.

- Infrared thermography to detect moisture ingress (>5% differential).

B. Severe Environmental Conditions (Coastal/Industrial Zones)

Quarterly Cleaning Protocol

- Salt Mitigation:

- Pre-rinse with deionized water to neutralize chloride ions.

- Apply glycol-based inhibitors post-cleaning.

Bi-Annual Sealant & Coating Audit

- Critical Parameters:

- Sealant adhesion testing (ASTM C794) with minimum 500 psi requirement.

- Gloss retention measurement (>40% for PVDF coatings).

- Featured Snippet Opportunity: “How often should coastal aluminum curtain walls be inspected?”

C. High-Rise Specific Requirements

Climate-Adaptive Cleaning

- Wind-Driven Rain Regions: Increase cleaning frequency by 25% during monsoon seasons.

- Snow Load Areas: Postpone cleaning operations <0°C to prevent ice bonding.

Specialized Access Methods

- Rope Access Teams:

- IRATA-certified technicians for buildings >40m.

- Use articulated boom lifts for localized repairs below 60m.

D. Maintenance Frequency Decision Matrix

| Environmental Factor | Cleaning Interval | Inspection Frequency |

|---|---|---|

| Sulfurous Pollutants | 3-4 months | Quarterly |

| Salt Spray (km from coast) | <1km: 2 months | Bi-monthly |

| UV Index >7 | 4-5 months | Semi-annual |

| Traffic Pollution (PM2.5) | >35μg/m³: 3 months | Quarterly |

VIII. Common Mistakes in Cleaning and Maintenance of Aluminum Curtain Wall Panels

Proper cleaning and maintenance are crucial for preserving the aesthetic appeal and structural integrity of aluminum curtain wall panels. However, several common mistakes can compromise their longevity and performance. This article highlights these pitfalls and provides guidance on avoiding them.

Using Strong Acidic or Alkaline Cleaners, Damaging the Surface Oxide Layer

- Issue: Harsh cleaners (pH <6 or >8) can corrode the aluminum oxide layer, leading to surface roughness, discoloration, and reduced corrosion resistance.

- Solution: Opt for neutral cleaners (pH 6-8) specifically formulated for aluminum surfaces. Avoid chlorine-based agents, which can trigger pitting corrosion.

Employing Abrasive Tools Like Steel Wool or Stiff Brushes

- Problem: Abrasive materials scratch the panel surface, creating micro-cracks that accelerate corrosion and degrade the protective coating.

- Recommendation: Use soft-bristle brushes, non-abrasive sponges, or low-pressure water jets (<1500 psi) to prevent physical damage.

Overlooking Safety Measures During High-Altitude Operations

- Risk: Neglecting fall protection, improper equipment use, or unqualified personnel can result in fatal accidents or material damage.

- Best Practice: Adhere to IRATA or local safety standards. Engage certified teams equipped with dual-rope systems, harnesses, and specialized access equipment (e.g., boom lifts).

Inadequate Rinsing After Cleaning, Leaving Chemical Residues

- Consequence: Residual cleaners containing surfactants or acids/alkalis promote electrochemical corrosion, especially in coastal or high-humidity environments.

- Correct Approach: Thoroughly rinse panels with deionized water post-cleaning. Use pH test strips to verify neutral residue levels.

Focusing Solely on Surface Cleaning, Neglecting Sealants and Fasteners

- Overlooked Areas: Sealants degrade due to UV exposure and thermal cycling, leading to water infiltration. Loose or corroded fasteners compromise structural stability.

- Preventive Action: Include sealant adhesion tests (e.g., ASTM C794) and fastener torque checks in maintenance schedules. Replace damaged components promptly.

Appendices

A. Glossary of Terms

| Term | Définition |

|---|---|

| KYNAR 500® | A fluoropolymer resin-based coating offering superior UV resistance and color retention for aluminum surfaces. |

| AAMA Standards | Specifications developed by the American Architectural Manufacturers Association for fenestration products, including curtain walls. |

| ASTM Standards | Testing and material standards published by ASTM International, widely referenced in the U.S. construction industry. |

| GB Standards | Mandatory national standards in China, regulating product quality, safety, and performance across industries. |

| Anodisation | An electrochemical process creating a durable oxide layer on aluminum for corrosion protection. |

| Electrostatic Powder Coating | A method applying dry powder paint to aluminum via electrostatic charge, cured in ovens for a uniform finish. |

| Silicone Sealant | A flexible, weather-resistant material used to seal joints and gaps in curtain wall systems. |

B. Cleaner Compatibility Chart

| Cleaner Type | Compatibility with Aluminum Surfaces | Notes |

|---|---|---|

| Neutral pH (6-8) | ✓ Compatible | Safe for anodized/coated panels. |

| Acidic (pH <6) | ✗ Avoid | Risks corrosion; use only for heavy oxidation removal under professional supervision. |

| Alkaline (pH >8) | ✗ Avoid | May damage protective coatings; test in inconspicuous areas first. |

| Chlorine-Based | ✗ Strictly Avoid | Causes pitting corrosion; never use. |

| Solvent-Based | ! Use with Caution | May degrade coatings; wear gloves/respirators. |

| Biodegradable | ✓ Preferred | Eco-friendly options often neutral pH; check manufacturer specs. |

C. Global Curtain Wall Code Index

| Region | Standard/Code | Key Requirements |

|---|---|---|

| China | GB/T 21086-2007, GB 50210-2018 | Mandates structural safety, thermal performance, and weather resistance. |

| USA | ASTM E283, ASTM E330 | Tests for structural performance and water penetration resistance. |

| EU | EN 13830, EN 13501 | Focuses on fire safety, thermal insulation, and air permeability. |

| Australie | AS/NZS 4284 | Specifies wind load resistance and watertightness for high-rise buildings. |

| Singapore | SS 552 | Regulates curtain wall design, materials, and installation for tropical climates. |

D. Typical Failure Case Atlas

Case 1: Corrosion from Acidic Cleaner

- Description: Surface etched by hydrochloric acid cleaner, exposing bare metal to oxidation.

- Solution: Replace affected panels; use neutral cleaners (pH 7-8) henceforth.

Case 2: Sealant Degradation

- Description: UV-induced hardening of sealant led to water leakage into building envelope.

- Solution: Remove old sealant, apply new silicone compliant with ASTM C920.

Case 3: Fastener Corrosion

Case 4: Coating Delamination

- Description: Pressure washing at >2000 psi damaged powder coating adhesion.

- Solution: Repaint after surface preparation; limit pressure to <1500 psi.

Case 5: Water Infiltration

- Description: Poorly sealed joints allowed rainwater penetration.

- Solution: Conduct ASTM E331 water penetration test; reseal gaps with PU foam.

Note: Actual images/diagrams would replace placeholders in a formal document.