Strong, sleek, and budget-wise—aluminum cladding that laughs at weather and lifts your skyscraper game without weighing you down.

You wouldn’t hang drywall on a skyscraper, right? Same logic goes for exteriors. Aluminum cladding is what serious builders reach for when they need something that won’t buckle under pressure—or rust in the rain. It’s strong but light, sleek without being flashy, and plays nice with both architects and accountants.

One project manager from Wallnova put it plainly this spring: “When you’re sourcing thousands of square feet, weight equals cost. Every pound counts—on your crane and your ledger.”

Folks in procurement don’t just want pretty panels—they want smart ones. Ones that ship tight, install fast, shrug off salt air or desert sun, and check all the ASTM boxes without busting the budget.

So if you’re hunting for cladding that’ll hold its own on 50 stories—and still look sharp doing it—you’re in the right spot.

Why Aluminum Cladding Is a Game-Changer for Commercial Architecture

Aluminum cladding isn’t just sleek—it’s shaking up how cities look, breathe, and age. Let’s break down why it’s such a big deal.

How Lightweight Extruded Panels Transform High-Rise Facades

- Extruded panels reduce the dead load on skyscrapers.

- Lower weight means faster crane lifts and quicker panel installation.

- Less structural stress = longer building lifespan.

- Engineers love how lightweight materials simplify facade retrofits.

- Architects get more freedom designing intricate building envelopes.

- Installers save time and labor on tall structures.

• The combo of strength and lightness in aluminum makes it ideal for high-rise design.

Tall buildings demand materials that won’t buckle under pressure—or cost. That’s where extruded aluminum shines. With its high strength-to-weight ratio, even complex shapes stay stable without needing bulky support systems.

It also plays nice with other materials in hybrid designs—glass, stone, or composites—making it flexible across styles and budgets.

You’ll also find that modular systems using these panels bring down both costs and risks during construction, especially when working hundreds of feet above ground.

Weatherability and Corrosion Resistance: A New Standard

- Long-term durability comes from top-tier corrosion protection.

- UV-resistant coatings fight off fading and chalking over time.

- Coastal buildings benefit most from salt-spray-tested finishes.

- Marine-grade aluminum alloys outperform steel in moist environments.

- Advanced powder coatings boost surface resilience against acid rain.

- Fewer maintenance cycles save owners serious cash long-term.

• Even extreme heat or cold doesn’t compromise performance thanks to thermally stable surface treatments.

“According to the 2024 Global Building Materials Outlook by Frost & Sullivan, aluminum-based facades now account for over 38% of new commercial projects due to their superior weather resistance.”

That stat alone tells you: this isn’t just hype—it’s the new baseline for performance in harsh climates.

Visual Impact Unleashed Through Custom Texture Options

Multiple short descriptive segments structure:

Brushed textures create soft reflections that shift throughout the day—perfect for dynamic urban lighting.

Matte finishes offer a subdued elegance that complements both modern glass towers and traditional brick surroundings.

Embossed surfaces add tactile depth, changing how light hits each panel depending on angle and sun position.

Designers are leaning hard into these options because they allow them to personalize every inch of a building’s skin without sacrificing performance or adding weight. Whether it’s mimicking natural stone or going full industrial chic, these custom touches change everything about what we expect from metal skins today—and tomorrow too.

With so many choices baked into one material system, it’s no wonder architects keep coming back to aluminum cladding again and again.

The Benefits of Using Aluminum Cladding in Commercial Buildings

Aluminum cladding brings serious perks to commercial spaces—think energy savings, low upkeep, and sleek designs that pop.

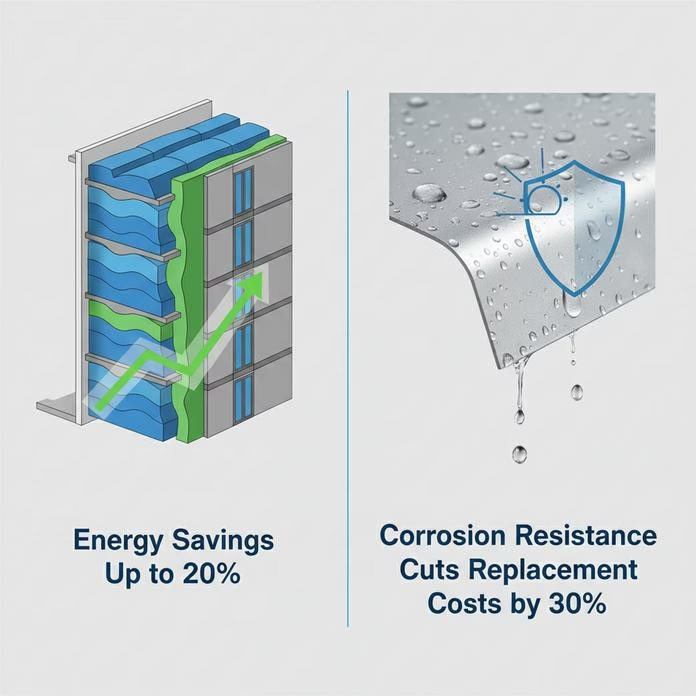

Enhanced Thermal Insulation for Energy Savings

- Improves thermal performance by reducing both heat gain and loss.

- Lowers the building’s U-value, helping meet strict energy codes.

- Keeps interiors cooler in summer, warmer in winter—cutting down on HVAC use.

- Integrated foam cores or mineral wool boosts insulation properties.

- Built-in thermal breaks prevent conductive heat flow through metal components.

- Helps create a tighter building envelope, minimizing air leaks.

☑️ Wallnova’s systems offer top-tier energy efficiency with minimal bulk.

Commercial buildings wrapped in high-performance aluminum panels experience measurable drops in power consumption. That’s not just good for the planet—it’s great for your wallet too.

Low Maintenance Thanks to Durable Coil Coating and Anodizing

• Surfaces are treated with advanced coil coating, making them resistant to grime and UV rays.

• The anodizing process creates a hard outer layer that won’t flake or peel like paint can.

- No need for frequent repainting—saves time and money long-term.

- Excellent corrosion resistance, even in coastal or industrial zones.

- High-end finishes retain color due to exceptional UV stability.

Forget pressure washing every month—these panels practically clean themselves with rainwater thanks to their smooth, dirt-shedding textures.

Seamless Installation with Advanced Fastening Systems

A smart setup starts behind the scenes:

- Hidden clips and brackets allow fast alignment without visible screws.

- Modular panel designs fit snugly into a pre-engineered subframe.

- Clean seams give off that crisp modern vibe while maintaining structural integrity.

Wallnova’s approach uses precise installation techniques paired with clever back-end engineering like floating rails and adjustable anchors—ensuring panels sit flush no matter what the wall throws at you.

Design Flexibility Through Custom Color Palette and Texture Options

Color your brand into the walls:

- Choose from hundreds of hues in matte, gloss, or metallic finishes.

- Mimic woodgrain or stone using textured surface treatments.

- Mix tones across elevations for added depth and drama.

→ Architects love how customizable it is: match corporate colors or go bold with contrast tones without sacrificing performance.

From smooth brushed aluminum to rugged embossed surfaces, these options support both subtle elegance and eye-catching flair—all while maintaining strong material aesthetics rooted in durability and style thanks to advanced surface treatment methods like powder coating or sandblasting effects.

Aluminum Cladding: Cost-Efficiency and Long-Term Durability

Aluminum cladding keeps costs low and performance high—smart for both builders and budgets.

Packaging Requirements and Shipping Methods for Cost Reduction

Efficient packaging of aluminum cladding panels isn’t just about safety—it’s a money-saver too.

- Tight packaging specifications cut down on breakage during transit.

- Smart containerization allows more units per shipment, reducing trips.

- Using rail or sea over air slashes costs by up to 60%.

- Evaluate panel dimensions to maximize truckload capacity.

- Choose reusable crates to reduce material waste long-term.

Lighter packaging options also mean less fuel burned.

By combining custom-fit crates with optimized shipping logistics, companies can slash freight bills while keeping the product pristine.

Panel Weight Savings and Lower Transport Expenses

Lightweight aluminum panels are a game changer in transport economics.

- Less weight = more payload room per truckload.

- Lower gross vehicle weight = improved fuel efficiency on long hauls.

- Higher stacking capacity = fewer shipments needed overall.

Each kilogram shaved off the panel’s design translates directly into cost savings across the supply chain.

Shorter delivery cycles, reduced emissions, and minimized handling effort make lightweight materials a win-win for both contractors and logistics teams alike.

Certifications and Standards: ASTM and EN for Proven Durability

Durability isn’t guesswork—it’s certified through rigorous testing under global standards like ASTM E84 or EN 13501.

“Products that meet EN standards show up to 40% longer resistance against corrosion in salt spray tests,” according to Euroconstruct’s Q1 2024 report.

- ASTM ensures fire resistance, impact strength, thermal stability.

- EN focuses on weathering, UV exposure, surface wear.

- Compliance with these durability standards is often mandatory in modern building codes worldwide.

Together, these certifications provide peace of mind—your material specifications aren’t just strong; they’re proven by science-backed benchmarks that hold up over time.

Is Aluminum Cladding Worth the Investment for Commercial Buildings?

Smart buildings start with smart skins. Let’s break down why aluminum cladding might just be your building’s best long-term bet.

How Does Thermal Insulation Boost Your Building’s Energy Savings?

Better insulation means fewer climate control headaches. Here’s how thermal insulation through aluminum cladding makes a difference:

- Primary Envelope Layering

- External thermal envelope wraps reduce heat transfer.

- Reflective coatings push back solar gain, lowering HVAC strain.

- Interior Temperature Regulation

- Stable internal temps slash both heating costs and cooling costs.

- Less fluctuation = less wear on mechanical systems.

- Energy Efficiency Metrics

- Higher R-values directly correlate with reduced annual energy use.

- Building Performance Payoff

- Lowered monthly bills

- Smaller carbon footprint

- Happier tenants in commercial spaces

In short, better-insulated walls mean more money stays in your pocket—and less escapes through the roof or facade.

Constant Repairs Draining Budgets? Durable Coil-Coated Panels Deliver

If you’re constantly patching up your building’s exterior, you’re probably bleeding cash. Here’s why switching to coil-coated panels is a no-brainer:

• These panels are built tough—resisting scratches, UV rays, and grime buildup.

• Their advanced surface finish means repainting cycles stretch out by decades.

• Fewer repairs = lower long-term maintenance costs and less downtime for tenants.

With their extreme durability, these panels help avoid recurring repair bills that pile up year after year. You’ll notice fewer calls to the maintenance team—and fewer headaches on your balance sheet.

Data Insight: Corrosion Resistance Cuts Replacement Costs by 30%

When exposed to harsh weather, traditional materials corrode fast—costing you big time. But not so with high-grade corrosion-resistant aluminum cladding.

Here’s how it stacks up:

| Material Type | Avg Lifespan (Years) | Annual Maintenance ($/sq ft) | Replacement Cycle Cost Index |

|---|---|---|---|

| Standard Steel Panel | ~15 | $1.25 | High |

| Fiber Cement Board | ~20 | $0.90 | Moderate |

| Coil-Coated Aluminum | >35 | $0.40 | Low |

With superior resistance to salt spray, acid rain, and urban pollutants, these panels preserve their structural integrity far longer than cheaper alternatives—trimming down replacement costs by roughly a third over the product lifecycle.

Are Environmental Certifications Aligning with Your Sustainability Goals?

Going green isn’t just trendy—it pays off when it comes to materials like aluminum cladding, especially if you’re chasing certifications like LEED or WELL.

• Most systems use recyclable alloys that meet strict low-VOC standards.

• Improved energy efficiency supports reduced operational emissions—great for hitting net-zero targets.

• Using eco-friendly finishes can even earn extra points under major green certification programs.

So if your business is serious about cutting its carbon footprint and boosting its green image, this is one material that walks the talk while ticking all the right boxes for modern sustainability benchmarks.

How to Select the Best Aluminum Cladding for Your Commercial Project

Finding the right aluminum cladding setup isn’t just about looks—it’s about safety, strength, and long-term performance.

Step 1 – Assess Corrosion Resistance, Fire Rating, and Thermal Insulation

To keep your building safe and efficient, don’t skip these three checks:

- Use alloys with high corrosion resistance, especially if you’re near coastal zones or industrial areas.

- Ensure panels meet national or local fire rating codes—Class A is often required for commercial facades.

- Look for integrated cores that provide strong thermal insulation, reducing HVAC loads year-round.

Together, these features shield your project from weather damage, fire hazards, and energy waste—three things you don’t want sneaking up later.

Step 2 – Compare Panel Thickness, Dimensions, and Surface Finishes

Choosing panel specs isn’t just technical—it affects how your building performs under pressure. Literally.

| Feature | Recommended Range | Why It Matters |

|---|---|---|

| Panel Thickness | 3mm–6mm | Handles wind loads & adds rigidity |

| Panel Dimensions | Up to 1500mm x 5000mm | Reduces joints; cleaner aesthetics |

| Surface Finishes | PVDF/Anodized | Boosts UV protection & visual appeal |

Match thickness with wind zone ratings. Choose a finish that stays sharp even after years of sun exposure. Bigger panels? Fewer seams.

Step 3 – Evaluate Coil Coating, Anodizing, and Powder Coating Options

Different coating styles bring different perks:

• Coil coating: Great for large runs; offers consistent color and strong adhesion.

• Anodizing: Enhances corrosion resistance while giving a metallic sheen—ideal for modern builds.

• Powder coating: Thicker coverage; good scratch resistance but needs precise application conditions.

Pick based on what matters most—durability? Gloss retention? Color depth? Each type has its sweet spot depending on your facade goals.

Step 4 – Verify Fastening Systems and Subframe Compatibility

Before installation kicks off, double-check how everything connects:

- Confirm that the chosen fastening systems align with both vertical loads and lateral wind pressures.

- Check whether the cladding fits onto steel or aluminum subframes without needing custom brackets.

- Ensure every part—from clips to anchors—is compatible with the panel material.

That way you’re not stuck modifying parts on-site. When your system clicks together cleanly, install time drops—and so does risk of failure later on.

Step 5 – Check Standards, Delivery Schedule, and Packaging Requirements

No one wants delays or damaged goods showing up at the jobsite:

• Confirm product meets local construction codes and industry-wide standards, like ASTM or EN norms.

• Get an accurate delivery timeline upfront—especially important if you’re coordinating multiple trades.

• Review how panels are packed—tight wrapping prevents scratches during transport while corner guards reduce impact damage.

Smart planning now saves headaches later when timelines are tight and crews are waiting around.

FAQs about Aluminum Cladding

1. Why is aluminum cladding preferred for modern high-rises?

Aluminum stands out because it holds strength without heavy mass—its lightweight body lessens structural load yet keeps façades strong against time.

- Its corrosion resistance fights weather and pollution, a quiet guard in the skyline.

- Coil coating, anodizing, or even precise powder coating adds lasting color and surface charm without frequent refinishing.

- Builders love how easy transport becomes: reduced panel weight trims shipping fuel use while fitting tighter project timelines.

2. How do insulation and fire ratings influence energy performance and safety?

The clever mix of thermal insulation layers, compliant with strict ASTM standards, keeps interiors cooler in summer and warmer when winds turn sharp.

1) Lower HVAC loads mean measurable savings on power bills each season; comfort stretches longer through efficient energy flow control.

2) High-grade cores with certified fire rating compliance ensure occupants are protected within building-code-approved limits; panels remain true even under pressure from radiant heat.

3. What installation details shape both look and cost efficiency on-site?

Behind every sleek wall lies an orchestra of hidden mechanisms—each part tuned for purpose:

✓ Hidden-clip or interlocking-based fastening systems keep joints neat; no screws distract the viewer’s eye line.

✓ Careful management of ventilation gaps, proper edge treatment, and compatible subframes improve façade breathing, preventing moisture entrapment that threatens long-term stability.

✓ With lighter loads, installers move quicker—shorter scaffolding hours lower site costs while preserving clean visual lines across every panel geometry and texture finish dreamed by designers under steel-blue skies.