1. Introducción a las paredes cortina de paneles de aluminio

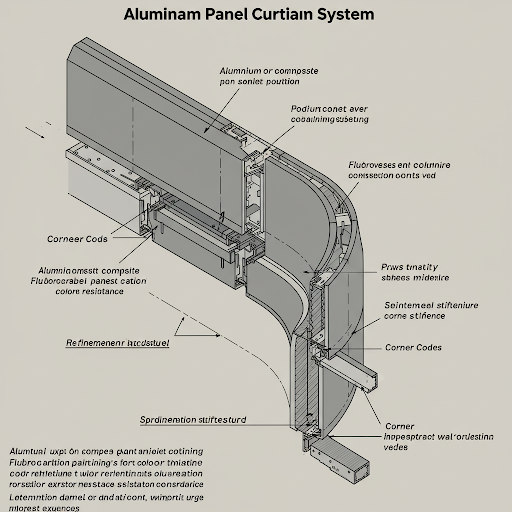

En pared cortina de panel de aluminio es un sistema de revestimiento exterior versátil que combina marcos de aleación de aluminio con diversos materiales de relleno como placas de aluminio, vidrio o paneles compuestos. Esta fachada diseñada no solo protege los edificios sino que también mejora su atractivo estético. Los componentes clave incluyen:

- Paneles: Normalmente paneles de aluminio o compuestos de 1.5 mm+ de grosor (por ejemplo, capas de aluminio de 0.5 mm que rodean un núcleo de polietileno de 3-4 mm).

- Revestimientos: La pintura fluorocarbono garantiza una retención del color de 25 años y resistencia a la corrosión.

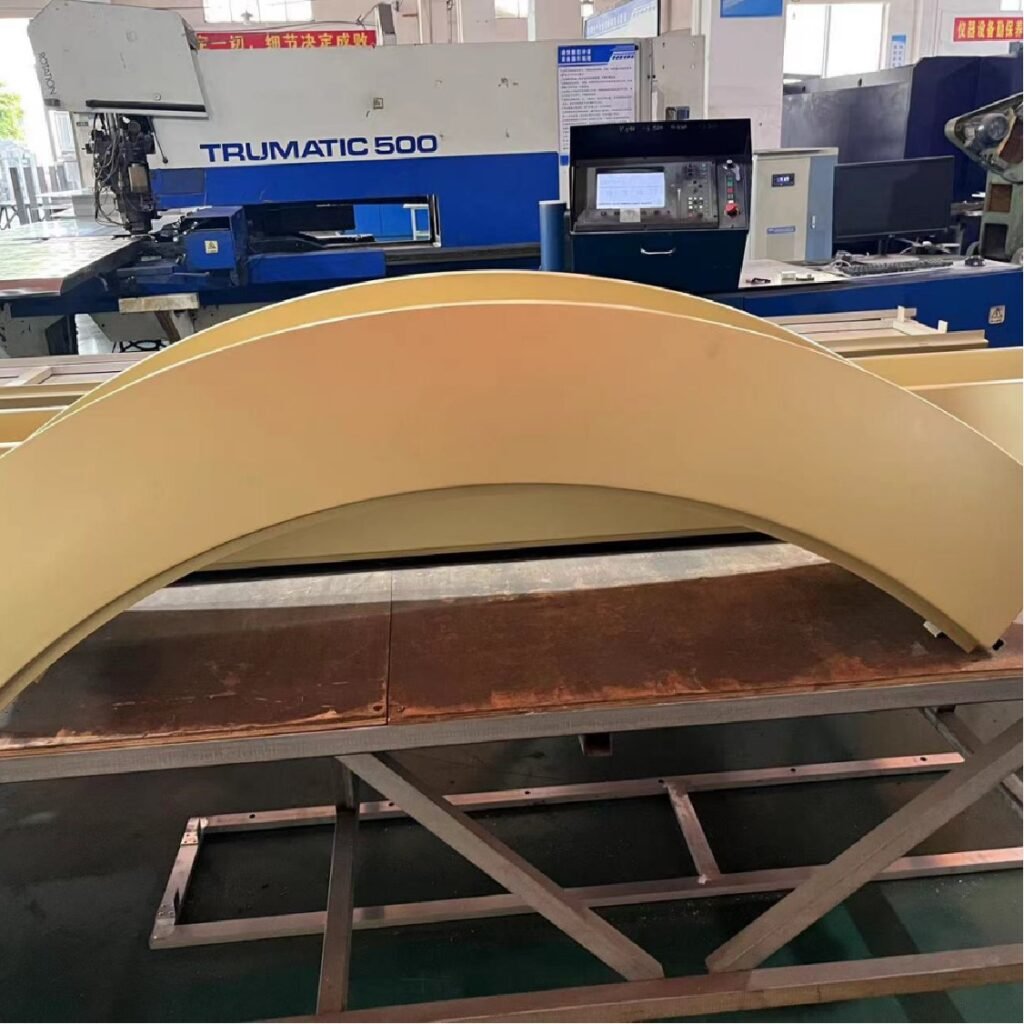

- Estructura: Los refuerzos y códigos de esquina refuerzan los paneles, permitiendo formas complejas como arcos o esferas.

2. Evolución y Dinámica del Mercado

2.1 Desarrollo Histórico

- 1970s-1990s: Surgió la industria de paredes cortina de aluminio en España, pasando de vidrio a paneles metálicos debido a su flexibilidad de diseño.

- 2000s-Presente: Los avances en materiales compuestos y revestimientos (por ejemplo, PVDF) expandieron las aplicaciones, con el aluminio dominando ahora los mercados globales.

2.2 Factores de Crecimiento

- Urbanización: El rápido desarrollo de las ciudades impulsa la demanda de fachadas modernas y duraderas.

- Políticas Verdes: Los estándares como GB/T 34327-2017 promueven materiales ecológicos y reciclables.

- Innovación: Las líneas de producción automatizadas y los recubrimientos inteligentes mejoran la eficiencia y el rendimiento.

3. Ventajas de las fachadas cortina de paneles de aluminio

3.1 Durabilidad inigualable y resistencia a la corrosión

Muros cortina de paneles de aluminio sobresalen en entornos adversos, gracias a la capacidad natural del aluminio para formar una capa protectora de óxido. Esto los hace ideales para áreas costeras o con alta humedad donde la corrosión es una preocupación principal. Cuando se tratan con anodizado o recubrimientos fluorocarbonados (PVDF), estos paneles resisten la decoloración, el blanqueo y la corrosión durante más de 25 años. Las pruebas rigurosas muestran una degradación mínima incluso después de una exposición prolongada a rayos UV, lluvia ácida y salpicaduras de sal, asegurando un atractivo estético y una integridad estructural a largo plazo.

3.2 Resistencia estructural que cumple con la eficiencia ligera

A pesar de su composición ligera, paneles de aluminio ofrecen ratios impresionantes de resistencia y peso. Con resistencias a la tracción de hasta 280 N/mm², soportan cargas de viento extremas y fuerzas sísmicas, lo que los hace perfectos para edificios de gran altura y regiones propensas a tormentas. Su naturaleza ligera reduce la carga total del edificio, simplificando el diseño estructural y bajando los costos de cimentación. Esta ventaja es particularmente crítica en zonas sísmicas o áreas con condiciones de suelo blando.

3.3 Versatilidad estética y flexibilidad en el diseño

Los arquitectos prefieren las fachadas cortina de paneles de aluminio por su libertad de diseño. Disponibles en colores sólidos, acabados metálicos o texturas de madera/piedra, estos paneles se adaptan a cualquier estilo arquitectónico—desde torres corporativas minimalistas hasta lugares culturales vanguardistas. Pueden ser curvados, perforados o combinados con elementos de vidrio y metal para crear fachadas dinámicas. Por ejemplo, el complejo residencial Tangchen Yipin en Shanghai utiliza paneles anodizados en oro para un aspecto lujoso y moderno, mientras que la Torre Princess en Dubái los integra en un sistema de vidrio y aluminio unitizado para una elegancia sin costuras.

3.4 Rendimiento térmico y eficiencia energética

Cuando se combinan con tecnología de ruptura térmica o núcleos aislantes, los paneles de aluminio mejoran significativamente la eficiencia energética. Las rupturas térmicas interrumpen la transferencia de calor, reduciendo las fluctuaciones de temperatura interior y el consumo de energía del HVAC hasta en un 30%. En climas fríos, esto significa costos de calefacción más bajos; en regiones cálidas, menor demanda de refrigeración. Muchos sistemas ahora incorporan materiales reciclados o paneles fotovoltaicos, alineándose con los objetivos de sostenibilidad global y certificaciones de edificios verdes como LEED.

3.5 Sostenibilidad y reciclabilidad

Aluminio es un material 100% reciclable, y los paneles de fachada cortina a menudo están hechos de chatarra post-consumo. Esta producción en ciclo cerrado minimiza el impacto ambiental, reduciendo las emisiones de carbono hasta en un 95% en comparación con la extracción de aluminio virgen. Con una vida útil superior a 30 años y necesidades mínimas de mantenimiento, estos paneles contribuyen a reducir los costos de ciclo de vida y los residuos de construcción. Su adaptabilidad en renovaciones extiende aún más su atractivo ecológico, ya que las estructuras existentes pueden actualizarse sin demolición.

4. Aplicaciones en diferentes industrias

Edificios Comerciales 4.1

- centros comerciales, oficinasy hoteles utilizan paneles de aluminio por su estética moderna y durabilidad.

Espacios Públicos 4.2

- Aeropuertos, hospitalesy museos priorizan sus beneficios en higiene, acústica y mantenimiento.

Proyectos Residenciales 4.3

- apartamentos de alta gama y villas adoptarlos para diseños elegantes y eficiencia térmica.

Ventajas y Aplicaciones de las Fachadas de Paneles de Aluminio 5

I. Edificios de Gran Altura y Complejos Comerciales: Eficiencia Estructural y Atractivo Estético

En estructuras super-altas, paneles de aluminio sobresalen en resistencia al viento y propiedades ligeras.

- Estudio de Caso de la Torre de Shanghái: El rascacielos de 632 metros emplea fachadas de aluminio personalizadas optimizadas mediante análisis de elementos finitos, soportando cargas de viento de tifón de grado 12 mientras reduce las cargas estructurales en 18% en comparación con el revestimiento de piedra.

- Híbridos de bajo consumo energético: El distrito central de negocios de Beijing integra fachadas de vidrio y aluminio, logrando un ahorro energético de 40% mediante coeficientes de sombreado ajustables y sistemas de muro cortina transpirable.

- Economía del ciclo de vida: Aunque las inversiones iniciales son mayores, los costos del ciclo de vida son 35% más bajos que los materiales tradicionales, con valores residuales de hasta 80% debido a su reciclabilidad.

II. Edificios residenciales: Elevando la estética con bajo mantenimiento

Los proyectos residenciales premium aprovechan la durabilidad del aluminio y la flexibilidad en el diseño.

- Desarrollos de lujo en Hangzhou: Los paneles recubiertos con fluorocarbono de 3 mm garantizan una retención del color de 25 años, aumentando el valor de la propiedad en un 18% en distritos exclusivos.

- Tecnología autolimpiable: Los paneles nanocortados en Ningbo reducen los costos de limpieza en 60,000 CNY anualmente, con un 80% menos de contaminación superficial en comparación con recubrimientos convencionales.

- Tendencias en personalización: Las renovaciones de villas en Shenzhen que utilizan paneles con textura de madera y piedra lograron una prima del 12% en los precios de reventa debido a un mayor atractivo exterior.

III. Edificios públicos: Durabilidad funcional para espacios de alto tráfico

La infraestructura pública exige resistencia y adaptabilidad estética.

- Teatro de la Ópera de Guangzhou: Paneles de aluminio de doble curvatura, fabricados con una precisión de 0.5 mm mediante BIM, acortaron la construcción en un 40% mientras creaban un hito cultural.

- Innovaciones en aeropuertos: La Terminal 4 del aeropuerto de Shenzhen utiliza paneles con respaldo de panal, logrando una reducción de ruido de 60dB y una mejora del 45% en la inteligibilidad del habla.

- Cumplimiento de la Seguridad contra Incendios: Los centros de convenciones adoptan paneles ignífugos clasificados como A2, que sobreviven a pruebas de fuego de 2 horas para garantizar una evacuación segura.

IV. Edificios Culturales y Educativos: Diseño Sostenible y Patrimonio

Las instituciones priorizan la sostenibilidad y el confort de los ocupantes.

- Segunda Biblioteca de Suzhou: Los paneles de aluminio perforados (porosidad 35%) aumentan la iluminación natural en un 30% y reducen el uso de energía en HVAC en un 18%, obteniendo la certificación LEED Oro.

- Espacios Educativos: Paneles mate de bajo deslumbramiento en escuelas internacionales de Shanghái reducen el deslumbramiento en las aulas de 82 a 45, cumpliendo con las normas de iluminación EN 12464.

- Simbolismo Cultural: El Museo de Cerámica de Jingdezhen integra patrones en azul y blanco grabados con láser en paneles ligeros, fusionando la tradición con la ingeniería moderna.