You ever stand outside a high-rise and think, “Dang, how does that thing still look brand new after battering wind, rain, and sun for years?” Well, odds are it’s rocking PVDF coated aluminum panels for exterior wall cladding—the unsung hero of modern buildings. These bad boys aren’t just about sleek looks; they’re built to take a beating while keeping their glow. If your project’s sweating over fading colors or corrosion creeping in after the first storm season, this might just be your golden ticket.

Truth is, materials matter when you’re stacking stories sky-high or wrapping up a luxury mall. Architects don’t gamble with facades—they spec coatings that pass AAMA 2605 like it’s religion. Because once those panels are up there? They’ve got to hold their own… year after year.

Key Points for Understanding PVDF Coated Aluminum Panels for Exterior Wall Cladding

- Material Selection Matters: Alloys like 3003 and 5052 are preferred for their strength, corrosion resistance, and compatibility with high-performance coatings.

- Weather Resistance is a Core Benefit: PVDF fluoropolymer coatings excel in UV protection and harsh environmental durability—ideal for long-term facade performance.

- Oversized Panels Offer Design Freedom: Large-format rainscreen systems simplify installation while elevating aesthetic appeal on commercial facades.

- Color Retention Enhances Longevity: Fade-resistant pigments ensure buildings maintain their visual impact over time without frequent repainting or replacement.

- Compliance Equals Confidence: AAMA 2605 certification guarantees the coating meets top-tier standards in weatherability, gloss retention, and colorfastness.

- Energy Efficiency Adds Value: These panels support thermal insulation goals, cutting down energy consumption and helping achieve LEED credits.

- Safety Comes Standard: Fire-resistant panel options are critical for meeting building codes—especially in high-rise applications.

- PVDF vs Powder Coat – Know the Difference: While powder coating suits interior uses or milder climates, PVDF outperforms in UV-heavy external environments.

- Custom Fabrication Supports Complex Designs: Custom-cut solutions make even intricate architectural visions achievable with clean lines and strong finishes.

- Modern Looks with Metallic Finishes: Mirror-like sheens elevate building prestige—perfect for towers aiming to stand out on city skylines.

Key Features Of PVDF Coated Aluminum Panels For Exterior Wall Cladding

PVDF coated aluminum panels bring together durability, style, and weather protection. Here’s what makes them tick for exterior wall cladding.

Material Choices: From Aluminum Alloy 3003 to 5052 Series

- Aluminum Alloy 3003 is known for its excellent workability and moderate strength—perfect when forming complex shapes.

- Aluminum Alloy 5052, on the other hand, steps things up with higher tensile strength and better marine-grade corrosion resistance.

- These alloys are widely used in exterior walls, especially where structural integrity meets aesthetic demands.

You’ll often see architects pick between these two based on whether they need more malleability (3003) or more toughness (5052). Both are lightweight yet strong metals, making them ideal for modern cladding systems.

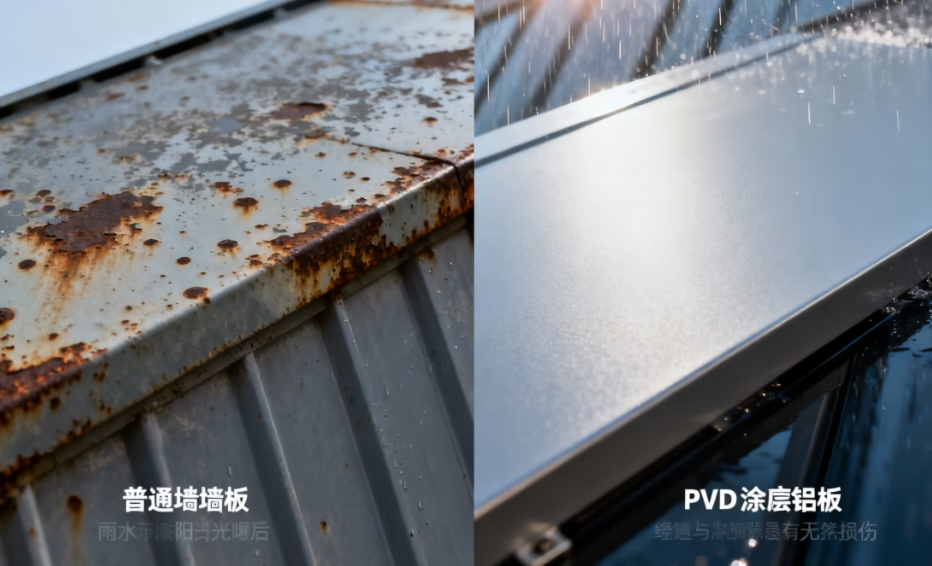

Superior Weather Resistance and Durability

- PVDF coatings shrug off UV rays like it’s nothing—sun won’t bleach your building anytime soon.

- Rain? Snow? Salt spray? Doesn’t matter. The coating resists it all thanks to its chemical makeup.

- And because of that, these panels last longer than most exterior materials out there.

The secret sauce lies in the molecular structure of the PVDF coating, which creates a barrier against oxidation and moisture intrusion—key culprits behind material degradation.

Oversized Aluminum Rainscreen Panel Systems

? Big panels = fewer seams = cleaner look. That’s why designers love oversized formats.

? They’re also faster to install due to reduced joint complexity—less cutting, less framing fuss.

? With flexible mounting systems, these panels adapt easily across different wall geometries.

Oversized aluminum rainscreen systems aren’t just about looks—they also improve airflow behind the facade, reducing trapped moisture and enhancing thermal performance.

Why Colorfast Fade-Resistant Pigments Matter

Color fade isn’t just annoying—it’s expensive over time when you have to repaint or replace panels early.

- Short-term exposure to UV can dull standard pigments fast.

- But with PVDF formulations loaded with colorfast pigments, color retention stays sharp for decades.

- This matters big-time in high-sun zones where building exteriors take a daily beating.

Bright reds stay red. Deep blacks don’t gray out after five summers under direct sunlight. That’s how long-term curb appeal is preserved without extra maintenance costs.

Meet AAMA 2605 Compliant PVDF Fluoropolymer Finish

| Feature | Requirement Standard | Achieved by PVDF Panels | Benefit |

|---|---|---|---|

| Color Retention | ≥5 years | Up to 15 years | Long-lasting finish |

| Chalk Resistance | ≤8 rating loss | ≤4 rating loss | Maintains appearance |

| Gloss Retention | ≥50% | Often >70% | Keeps visual impact |

| Humidity Resistance | No blistering | Pass | Zero internal damage |

AAMA 2605 compliance means these coatings pass brutal tests—think boiling water humidity chambers and salt fog exposure over thousands of hours. If your project demands top-tier performance, this is the gold standard for exterior finishes on metal cladding systems like those made with PVDF fluoropolymer coatings.

These features together make PVDF coated aluminum panels for exterior wall cladding not just functional but future-proofed—built tough while looking sharp through every season.

Key Benefits Of Pvdf Coated Wall Cladding

Explore how PVDF coated aluminum panels for exterior wall cladding blend performance, safety, and sustainability into one smart solution.

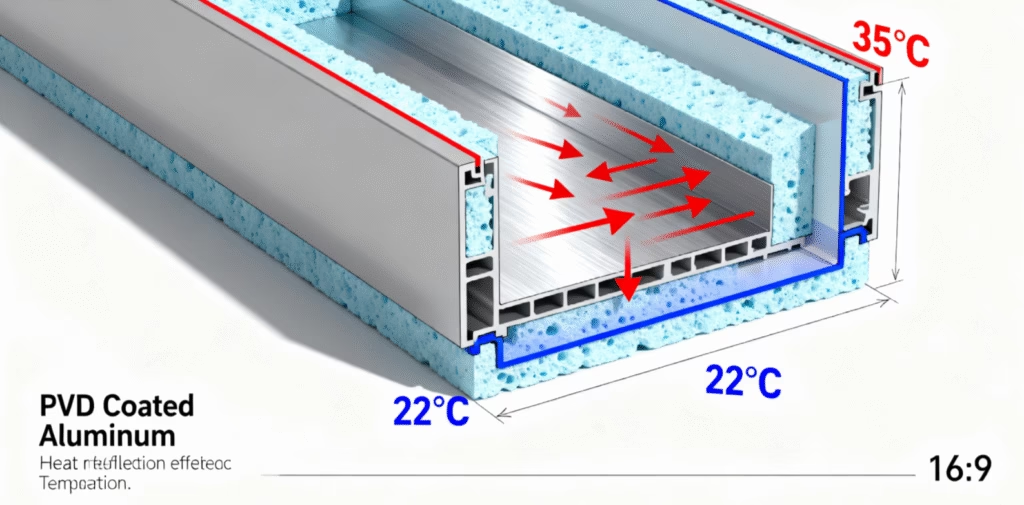

Energy Savings through Thermal Insulation Excellence

Cuts down on utility bills by reducing indoor-outdoor heat exchange.

Minimizes HVAC strain during peak summer and winter months.

Thermal insulation effect of PVDF coated aluminum panels for energy savings

- The thermal insulation properties of these panels help maintain a stable interior climate.

- That means less energy wasted—and more money saved over time.

— Keeps buildings cooler during heatwaves and warmer when it’s freezing out.

The special PVDF coating acts as a thermal barrier, reflecting solar radiation while sealing off air leaks around the building envelope. Combined with lightweight yet tough aluminum panels, this setup enhances comfort without cranking up the AC or heater.

Short-term savings show up fast, but long-term efficiency gains really stack up—especially across large surface areas like high-rises or office parks using full exterior walls coverage.

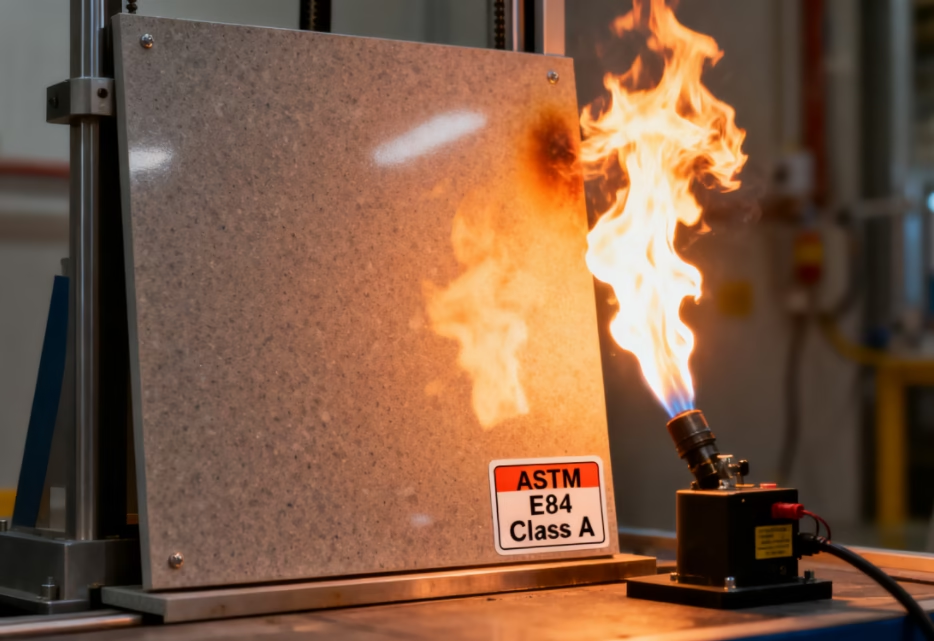

Boost Tenant Safety with Fire-Resistant Panel Options

Enhanced fire protection meets strict modern building codes.

Adds peace of mind for families and commercial tenants alike.

Fire doesn’t wait—and neither should your safety strategy. By choosing fire-resistant panels, developers can significantly reduce flame spread potential across the entire facade system.

Multiple short benefits include:

– Improved occupant evacuation time due to slowed ignition rates;

– Reduced structural damage from heat exposure;

– Compliance with international fire rating standards for exterior materials.

Backed by a durable layer of specialized PVDF coating, these systems protect not just property but lives too—especially critical in schools, hospitals, and high-rise apartments where tenant density is high.

Long-Lasting Appeal with Superior Corrosion Protection

You want your building looking fresh year after year? These panels got you covered—literally!

Step-by-step breakdown:

Step 1 – Surface is treated with anti-corrosive primer before applying the PVDF coating;

Step 2 – Coating resists acid rain, salt spray, UV rays, and industrial pollutants;

Step 3 – Result? Long-lasting color vibrancy and structural integrity across all seasons.

That means fewer repainting cycles and minimal upkeep costs over decades—even along coastal regions where corrosion usually eats metal alive. With their sleek finish and rigid core, these highly durable aluminum panels keep both form and function intact on any type of vertical buildout or curved fa?ade design across varied climates.

Green Building Credits: LEED Certified Sustainable Cladding

Earn LEED points under categories like Energy & Atmosphere + Materials & Resources;

Reduce environmental impact through recyclable components;

Support eco-conscious construction goals from design to delivery.

According to Dodge Construction Network’s Q2 Sustainability Report (2024), “buildings that incorporate certified sustainable materials such as PVDF-coated facades show an average increase of 19% in lease desirability among eco-conscious tenants.”

These advanced systems offer more than just good looks—they align perfectly with today’s green mandates using recyclable base metals like aluminum plus low-VOC finishes within the full assembly process of sustainable cladding solutions.

One-time installation pays off big when you’re chasing those coveted green building credits—and brands like wallnova make it easier than ever to meet those benchmarks without compromising style or durability.

Pvdf Vs. Powder Coated Panels

A quick comparison between two popular finishes used on aluminum panels for cladding—each with its own strengths depending on the climate, budget, and design needs.

PVDF Coated Aluminum Panels

When you’re looking at PVDF coating on aluminum panels, think long-term. It’s not just about the look—it’s about how that look holds up under punishing sun and rain.

- UV resistance? Top-tier. That’s thanks to the fluoropolymer base in PVDF resins.

- Rain or shine, these panels won’t chalk or fade like cheaper alternatives.

- The color retention is so strong that some facades still pop after two decades.

You’ll often find PVDF coated aluminum panels for exterior wall cladding on high-rises and coastal buildings where weather eats through lesser materials. According to a 2024 report from BCI Central, buildings using PVDF-coated fa?ades reduced repainting cycles by up to 40% over 15 years compared to powder-coated alternatives.

And while it costs more upfront, this stuff pays off when you factor in fewer repairs and less maintenance drama. If you’re playing the long game—especially in harsh climates—PVDF is where it’s at.

Powder Coated Aluminum Panels

Now let’s talk powder coating—it’s got a different vibe altogether. More affordable? Yep. A chameleon of colors? Absolutely.

Powder coating is applied via electrostatic charge, then baked till it’s tough as nails.

It works great for indoor settings or milder outdoor zones where UV isn’t a daily menace.

Budget-conscious projects love this option because it checks both aesthetic and cost boxes.

Grouped advantages:

– Variety of Colors: Choose from matte, gloss, textured—you name it.

– Cost-effective Finish: Ideal for short-term commercial builds or residential accents.

– Moderate Weather Resistance: Holds up fine unless you’re battling intense sun or salt air daily.

While not as durable as PVDF coated aluminum panels, powder-coated options still serve their purpose well when chosen wisely based on location and use case. For interior walls or protected exteriors, they often strike the perfect balance between style and spend.

Commercial Skyscraper: Pvdf Panels For Sleek Exteriors

Modern towers are pushing limits in height and design—PVDF coated aluminum panels for exterior wall cladding are what keep them looking sharp and staying strong.

How Do PVDF Panels Withstand High Wind Loads?

- Panel thickness, internal reinforcement, and anchoring systems help these panels shrug off high wind speeds.

- Engineers test them against hurricane-grade conditions using global testing standards like ASTM E330.

- Proper installation methods matter just as much—when done right, there’s no rattling or warping.

You’ll often see these panels rated to withstand pressures exceeding 2.5 kPa. That’s serious muscle. And the secret? A combo of smart geometry, flexible substrates, and precise mounting brackets. Together, they hold up the panel’s structural integrity, even when winds howl through city canyons.

Case Study: High-Rise Exterior Cladding Installation

| Project Name | Height (m) | Panel Area (sqm) | Completion Year |

|---|---|---|---|

| Aurora One | 212 | 7,500 | 2023 |

| SkyNest | 180 | 6,200 | 2022 |

| Vantage Bay | 230 | 8,100 | 2024 |

| Nova Edge | 205 | 7,000 | Ongoing |

Take the Vantage Bay Tower—it used over 8,000 sqm of PVDF panels. The process kicked off with scaffold planning and ended with a laser-guided final alignment check. Every step was tied to strict safety protocols, especially around crane lifts at height. The result? Zero delays and a flawless finish that shaved weeks off estimated timelines.

Mirror-Like Metallic Finish on Tower Facades

That shimmering glow you see from blocks away? It’s not just style—it’s science meeting art.

The high-gloss look comes from advanced PVDF coating, which includes aluminum pigments suspended in resin for maximum reflectivity.

As noted in the Q1–2024 report by ArchiBuild Analytics: “Demand for reflective facades has surged by over 18%, driven by luxury commercial projects across Asia-Pacific.” These finishes amplify daylight bounce while resisting UV fade—a win-win for both aesthetics and long-term durability.

Architects love how it complements glass curtain walls; developers love how it boosts perceived alue instantly.

Custom-Cut Panel Solutions for Complex Designs

Curved balconies? Irregular tower footprints? These aren’t problems—they’re opportunities when you’ve got precision-cut custom-cut panels on hand.

Each panel is tailored using CNC routing to match exact specs from BIM models—no awkward gaps or forced trims here.

This flexibility supports wild architectural ideas without compromising on fit or weatherproofing integrity.

Whether it’s layered fins or perforated shading screens, these solutions open up new possibilities in high-rise creativity using reliable PVDF coated aluminum panels for exterior wall cladding manufacturing techniques.

FAQs about PVDF Coated Aluminum Panels for Exterior Wall Cladding

What makes PVDF coated aluminum panels a smart choice for commercial exteriors?

It’s all about endurance and elegance. These panels stand tall against harsh sun, driving rain, and biting wind—year after year. The PVDF coating forms a resilient shield that resists fading and corrosion, keeping buildings looking sharp without constant upkeep. Architects love the clean lines; engineers trust the performance.

Can I customize the finish to match my building’s aesthetic?

Absolutely—and not just in color. You can choose from:

- Standard hues or custom RAL matches to fit your brand identity

- Sleek metallics that shimmer under changing light conditions

- Pearlescent effects that give depth and personality to large facades

This flexibility lets you shape more than just walls—it helps tell your story through design.

Do these panels help reduce energy bills over time?

Yes, they do more than protect—they perform. Thanks to their thermal insulation properties, these cladding systems act as an extra barrier between outdoor heat or cold and indoor comfort zones. That means HVAC systems don’t have to work as hard, which translates into lower energy consumption month after month.

Are there fire-safe options available for high-rise applications?

Safety isn’t optional—it’s essential. Many of these panel systems meet ASTM E84 Class A standards for flame spread and smoke development. Especially in taller structures where evacuation is complex, this level of protection adds peace of mind alongside code compliance.

How do oversized rainscreen panels benefit large-scale projects?Bigger isn’t always better—but in this case, it often is:

- Fewer seams mean cleaner lines across vast surfaces

- Larger coverage speeds up installation on tight schedules

- Custom sizing adapts easily to bold architectural visions

For developers racing deadlines or designers chasing precision symmetry across stories-high elevations—oversized rainscreens are game changers.

Why choose wallnova for your curtain walling?

More than 15 years of experience, excellent product quality, 20 years warranty.

1、• Experience & Expertise – Proven track record in designing, fabricating, and installing curtain wall systems.

2、• Technical Knowledge – Understanding of structural engineering, thermal performance, and weatherproofing.

3、• Quality Workmanship – High standards of fabrication and installation with attention to detail.

4、• Compliance & Certification – Certified and approved by leading industry bodies

- Innovative Solutions – Ability to provide energy-efficient and sustainable curtain walling options.

- Supply Chain – Strong relationships with material suppliers to ensure timely delivery and quality control.