Every building tells a story—and modern aluminum facade design is the bold punctuation mark at the end of that sentence. When budgets are tight, timelines tighter, and everyone’s got an opinion on “what looks good,” your exterior has to work overtime: impress investors, please planners, and still stand tall five storms later. You want style that doesn’t age like milk? Aluminum’s your friend.

One developer told me flat out: “I don’t have time for fussy installs or materials that sulk in salt air.” Fair point. With factory finishes built to outlast mood swings and clip systems so simple they’re practically plug-and-play, it’s no wonder this sleek metal is quietly stealing the spotlight across airports, hospitals—even stadiums.

Key Points to Elevate Every Project with Modern Aluminum Facade Design

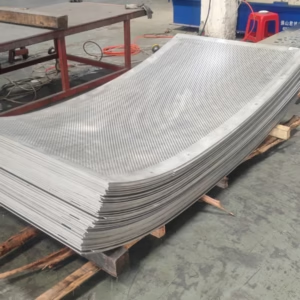

➔ Material Matchmaking: Choose from 6061, 5052, or 3003 aluminum alloys based on your project’s structural needs and environmental exposure.

➔ Finish Strong: Opt for PVDF coatings or anodized treatments to ensure long-lasting color vibrancy and UV resistance in any climate.

➔ Install with Ease: Use clip-on mounting hardware and adjustable brackets to streamline installation while allowing for thermal movement.

➔ Design Meets Durability: Variable depth configurations and interlocking joints improve insulation performance and reduce energy costs over time.

➔ Think Green Early: Maximize LEED potential by selecting panels with high recycled aluminum content and low-VOC coating systems.

➔ Weather the Storms: Confirm wind load, corrosion resistance, and fire rating compliance through rigorous testing standards before final inspection.

Guided Surprising Benefits Of Incorporating Aluminum Panels Into Modern Facade Style

Modern aluminum facade design keeps surprising architects and builders alike. Let’s break down the unexpected wins baked into these sleek, durable panels.

Discover 5052 Marine Grade Aluminum Defying Coastal Corrosion

- Marine-tested durability: 5052 alloy thrives in salty air—perfect for beachside buildings or harborside hotels.

- Resists pitting and oxidizing: Unlike cheaper metals, this one holds up without flaking or blistering.

- Flexible yet strong: It bends without breaking, which makes it ideal for curved contours in creative architecture.

- Pairs well with other materials: Whether you’re working with glass curtain walls or stone accents, this alloy blends seamlessly.

- Low upkeep charm: No need to baby it—just rinse off the salt once in a while and you’re golden.

- Compatible with high-performance coatings: Add a PVDF finish and it becomes nearly bulletproof against UV rays and acid rain.

How 3003 Aluminum Sheet Panels Slash Maintenance Costs Dramatically

- Naturally corrosion-resistant: Thanks to its manganese content, this panel shrugs off rust like it’s nothing.

- No need for constant repainting: Its surface resists fading and chalking—even under brutal sun exposure.

- Perfect match for urban builds: Smog? Acid rain? Industrial grime? This alloy doesn’t flinch.

- Lightweight but tough as nails: Cuts down on structural load without sacrificing integrity—a win-win during installation.

- Ideal base for finishes like powder coating or anodization, giving designers more visual control while keeping maintenance near zero.

Eco-Friendly Makeover with Recycled Aluminum Content for Green Facades

Aluminum panels aren’t just about looks—they’re also pulling their weight in sustainability goals.

• Many modern panels now contain over 50% post-consumer recycled content, drastically cutting down on embodied carbon during production.

• Builders love that recycled alloys still meet strict ASTM standards, especially when used in high-efficiency systems like ventilated rain screen cladding.

• According to a 2024 report by the Global Building Materials Index: “Recycled aluminum use has grown by over 32% in facade applications since 2020—driven largely by LEED v4 incentives.”

• These panels sync beautifully with digital workflows through tools like building information modeling (BIM)—helping teams track material origins and environmental impact in real time.

• When combined with energy-efficient insulation layers behind the skin, they help reduce HVAC load substantially over time.

Surprise Factor: PVDF Coating System Elevates Surface Longevity and Shine

You wouldn’t expect a coating to do so much heavy lifting—but PVDF isn’t your average paint job.

1) It locks in color like no other—buildings still pop after decades under harsh sun.

2) The slick finish repels dirt, graffiti, smog… even bird droppings don’t stand a chance.

3) It works hand-in-glove with both flat sheets and textured surfaces—including those made from extruded aluminum profiles.

4) Architects dig its design freedom—it comes in metallics, mattes, even faux stone textures that mimic natural finishes.

5) When applied over an anodized base layer or layered atop powder coating systems, you get double the protection.

6) Best part? It cuts long-term costs by reducing repaint cycles dramatically—especially handy on tall curtain wall systems where access is pricey.

In short: if you’re chasing visual wow factor plus real-world resilience in your next build-out using modern aluminum elements… PVDF is your secret sauce.

Layered Types Of Aluminum Facade Cladding Materials

A quick look at the most popular aluminum cladding materials—each with its own vibe, strength, and design potential for today’s facades.

6061 Aluminum Alloy Cladding Panels

This one’s the all-rounder. 6061 aluminum alloy is like the athlete of facade metals—tough, reliable, and easy to work with.

- High tensile strength makes it great for structural demands.

- Welds cleanly without compromising surface integrity.

- Responds well to machining and forming processes.

You’ll spot this alloy in modern cityscapes where strength meets sleekness. It’s often used in curtain walls that need both durability and sharp geometry. For those designing with modularity in mind, it’s a solid go-to.

5052 Marine Grade Aluminum Facade Panels

When salty air hits hard, 5052 marine-grade aluminum steps up.

• Corrosion resistance? Off the charts—ideal for coastal buildings.

• Slightly softer than other alloys but bends beautifully around curves.

• Maintains color integrity even under UV-heavy conditions.

It’s often paired with powder-coated finishes to enhance longevity while keeping costs down on maintenance over time. Think beach resorts and industrial parks near ports—it holds its own impressively.

3003 Aluminum Sheet Metal Systems

If you’re after affordability without skimping on style, 3003 aluminum sheet metal is your jam.

Short segments:

– Lightweight yet strong enough for decorative panels.

– Great for laser cutting intricate patterns.

– Works well with brushed or anodized finishes.

Designers love this one when going after fluid shapes or irregular patterns in urban facades. It molds easily into custom forms—kind of like clay but shinier and more weatherproof.

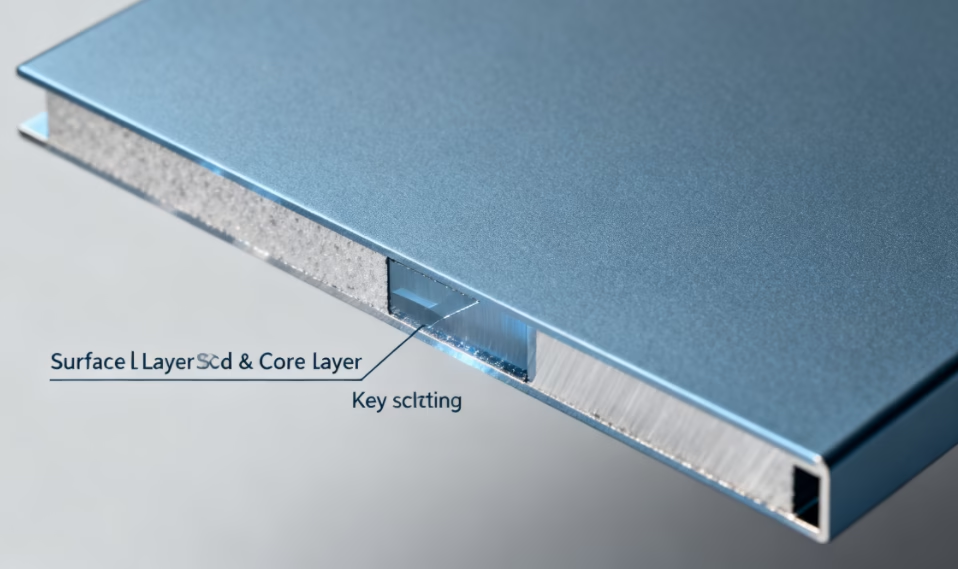

Anodized Aluminum Composite Panel Solutions

Here’s where tech meets texture: anodized composite panels are all about that modern edge—with a side of durability.

Grouped features:

• Dual-layer construction adds rigidity while staying light on load-bearing structures.

• Anodizing process builds up an oxide layer that resists scratches and fading longer than paint alone.

• Available in matte tones or mirror-like finishes for bold architectural statements.

| Feature | Benefit | Ideal Application | Durability Rating |

|---|---|---|---|

| Oxide Layer Thickness | Enhanced wear resistance | Commercial facades | High |

| Color Uniformity | Consistent appearance across panels | Corporate HQs | Medium |

| UV Stability | Reduced discoloration | Sun-exposed surfaces | High |

| Weight | Easier installation | Retrofit projects | Low |

According to BCI Central’s Q2/2024 Building Materials Insight Report, anodized aluminum saw a usage spike of nearly 18% year-over-year in Southeast Asian commercial projects due to its low-maintenance appeal and visual consistency across large-scale façades.

Powder-Coated Aluminum Extrusion Profiles

Color-rich and tough as nails—powder-coated extrusions are what give many facades their final pop.

Steps involved:

- Raw extruded profiles are cleaned via chemical pre-treatment.

- Electrostatic spray guns apply dry powder evenly across surfaces.

- Curing ovens bond the coating permanently through high heat.

- Final inspection ensures no bubbling, flaking, or uneven gloss levels before shipment.

These profiles come alive when used as sunshade fins or vertical blade elements in contemporary builds aiming for both function and flair in their cladding systems.

It’s worth noting how these coatings aren’t just pretty—they’re built to shrug off graffiti, acid rain, and even desert dust storms without losing their shine over time.

Comparative Aluminum Vs Composite Facades Which Wins

A quick showdown between two top dogs in facade materials—aluminum and composite. Let’s break down what really matters.

Aluminum Facades

You want sleek? Go aluminum. You want green? Still, go aluminum. This material doesn’t just show up—it sticks around.

• Resists corrosion like a champ, even when the weather turns nasty

• Lightweight yet strong enough to handle wild design ambitions

• Fully recyclable, which makes it a favorite for eco-conscious builds

1) It’s got a long shelf life—upwards of 40 years with minimal maintenance

2) Architects love its clean lines and how easy it is to shape into custom forms

3) Ideal for high-rise buildings where weight matters big time

✓ Bonus: It plays well with other materials—glass, stone, you name it

According to the 2024 Architectural Materials Review by BCI Central, over 60% of commercial projects in urban centers now specify aluminum cladding systems, citing performance consistency and environmental benefits.

It’s no surprise that wallnova has built its reputation around pushing the edge of modern exterior aesthetics using this very material.

Composite Facades

Composite panels bring together different stuff—metal sheets fused with cores like polyethylene or mineral wool—to offer more than one kind of benefit at once.

■ Better insulation thanks to dense core layers that trap heat or cool air inside

■ More color and texture options than almost any other cladding type out there

■ Often cheaper upfront than full-metal alternatives like aluminum

Grouped Advantages:

— Thermal Performance: Keeps interiors comfy without cranking HVAC systems all day

— Acoustic Dampening: Helps reduce street noise in busy neighborhoods or office parks

— Design Flexibility: Can mimic wood, stone, or even brushed metal looks without the cost

| Material Type | R-value (m²·K/W) | Avg Lifespan (Years) | Recyclability (%) |

|---|---|---|---|

| ACP Standard | 0.44 | 25 | 30 |

| Mineral Core | 0.70 | 30 | 40 |

| Solid Aluminum | 0.33 | 45 | 90 |

So while composites might not win gold in recyclability, they definitely show up strong in comfort and customization categories.

Both materials offer something solid—but your pick depends on what you’re chasing: form, function… or both.

Bulleted 4 Steps To Install Aluminum Facade Panels

Installing aluminum panels doesn’t have to be a headache. Here’s how to keep it slick, sturdy, and stylish from start to finish.

Assessing Custom Width Panel Sizes for Seamless Layout

• Getting the panel dimensions right means fewer awkward cuts and cleaner lines.

• For large builds, consider pre-measuring wall spans with laser levels for tighter fits.

• Avoid mixing widths—uniformity keeps your design looking polished and professional.

Shorter facade elements like window returns or corners benefit from narrower custom sizes, while uninterrupted walls look best with wider formats. Always plan layouts around symmetry and key visual axes.

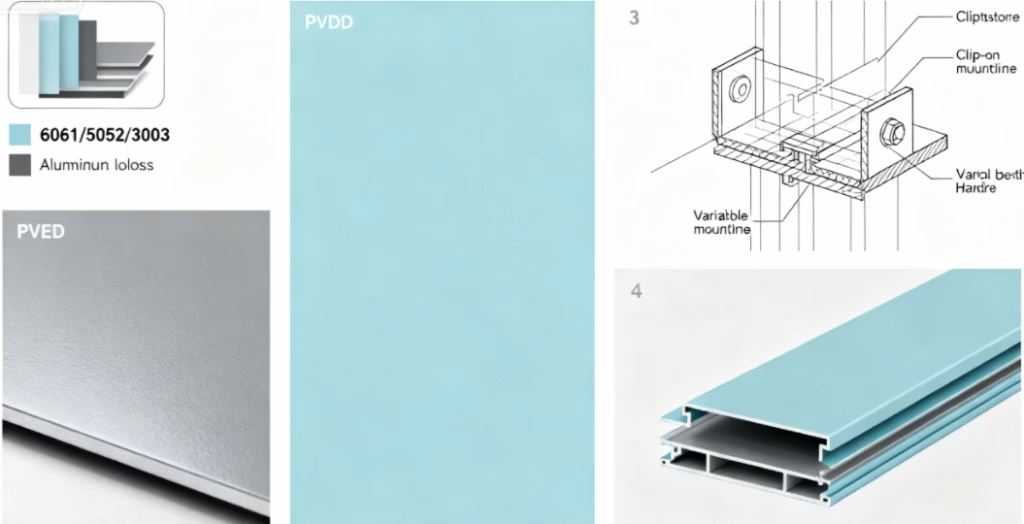

Securing Panels with Clip-On Mounting Hardware

- Snap-on systems reduce labor time—no screws visible on the face of your cladding material.

- Use stainless steel clips for corrosion resistance, especially in coastal or humid zones.

- Wallnova’s integrated clip kits come pre-aligned for faster installs—just click and go.

This type of hardware also allows for easy panel removal later if repairs or upgrades are needed down the line.

Aligning Sections Using Adjustable Bracket Support Structures

♦ Adjustable brackets are a game changer when dealing with uneven building envelopes.

These supports let you tweak elevation by millimeters without tearing things apart mid-job. That means less stress during install and better long-term durability as buildings settle or shift subtly over time.

Multiple anchor points also help distribute weight evenly across the facade system—critical when working with heavier gauge materials or taller elevations.

Final Inspection: Wind Load Resistance and Seal Testing

- Check that all seals around joints are continuous and unbroken—especially at corners.

- Confirm that every bracket is torque-tightened according to spec.

- Use a handheld anemometer to simulate wind pressure on test panels.

- Inspect expansion joints to ensure they haven’t been blocked by sealant overflow.

- Conduct a water hose test along vertical seams at medium pressure.

A clean bill of health here means peace of mind—and fewer callbacks months later when storms roll through your client’s neighborhood.

Pain-Point Struggling With Energy Costs Insulate Aluminum Facades Easily

Energy bills creeping up fast? These quick-fire strategies help you tame temperature swings while keeping your aluminum facade looking sharp and modern.

Skyrocketing Cooling Costs? Use Variable Depth Panel Configurations

When the summer heat hits hard, your building shouldn’t feel like an oven. Mixing up panel depths works wonders for airflow and insulation. Here’s how:

- Deeper panels trap more air, acting like a thermal buffer zone.

- Shallower sections allow better integration with shading elements.

- A mix creates turbulence that disrupts heat transfer.

This layering trick doesn’t just look sleek—it’s a smart move to boost the thermal performance of any panel system, especially when dealing with high-sun exposure zones. It’s all about cooling without cranking up the AC.

Frequent Heat Loss? Interlocking Panel Joint Seals Lock In Air

Losing warm air through tiny gaps might not sound like a big deal—but it adds up fast. Here’s how interlocking seals fix that:

• Airtight connections between panels reduce drafts during cold months.

• Precision-fitted joints prevent moisture seepage—no more hidden mold surprises.

• Thermal breaks within the seal design slow down heat transfer across materials.

• Flexible gaskets adapt to expansion and contraction with seasonal shifts.

Together, these features make your building envelope tighter, smarter, and way more energy-efficient—without sacrificing that clean-line look of modern aluminum cladding.

Failing Insulation Tests? Rely on Thermal Insulation Property Testing Standards

Failing those pesky energy audits isn’t just frustrating—it can stall projects altogether. But sticking to proper standards changes everything.

ASHRAE guidelines and ISO-certified testing methods ensure every layer of your insulated facade system performs as advertised. As BPI’s Q2 2024 report puts it, “Standardized testing has cut rework costs by nearly 18% across commercial retrofits.”

Short takeaways:

– Test before install to catch weak spots early.

– Always request certified results from suppliers.

– Match materials to climate-specific benchmarks—not generic ratings.

It’s not about passing tests for the sake of it—it’s about building smarter from blueprint to build-out.

LEED Goals Out of Reach? Embrace Recycled Aluminum Content

Going green doesn’t mean going broke—or boring. Using recycled material in your cladding system is one slick move toward sustainability credits without overhauling design intent.

Grouped Benefits:

■ Environmental Impact: Cuts down raw material extraction by over half per square meter installed.

■ LEED Points: Contributes directly under Materials & Resources credits—especially if sourced locally.

■ Design Flexibility: Recycled alloys still support custom finishes, colors, and patterns common in modern aluminum setups.

The best part? You don’t have to compromise on aesthetics or durability while hitting those eco-targets dead-on—even wallnova’s newer product lines are integrating post-consumer aluminum blends now.

Let your facade work harder for both comfort and certification goals at once.

FAQs about Modern Aluminum Facade Design

Why is 5052 marine grade aluminum a favorite for coastal buildings?

Salt air is relentless, but 5052 aluminum stands its ground. It resists corrosion like few others, making it a natural fit for seaside structures. Architects love pairing it with PVDF coatings—not just for the UV protection, but for the way it holds its color, year after year. From ferry terminals to oceanfront hotels, it’s the quiet hero keeping facades sharp and strong.

How does aluminum facade design help cut down on maintenance?

- 3003 aluminum panels resist rust and stains

- Fewer touch-ups and less frequent cleaning

- Ideal for sprawling apartment complexes or public housing

- Keeps buildings looking fresh without constant upkeep

What makes anodized aluminum composite panels stand out in renovations?

Renovating an old institutional building? Anodized panels bring new life without overwhelming the original character. Their surface is tough—resisting scratches and fading—and their clean, matte finish adds a modern edge. The best part? They age gracefully, holding their tone and texture even under harsh sun.

Can facade panel joints really impact a building’s energy use?

Absolutely. A well-designed interlocking joint isn’t just about looks—it’s a barrier. It locks in heat during winter, keeps cool air inside during summer, and helps the building breathe just enough. These joints play a quiet but powerful role in helping buildings meet energy codes and even qualify for LEED points.

Why are variable depth panels gaining popularity in hot regions?

- Allow air to circulate behind the panels

- Reduce surface temperature and solar heat gain

- Lower cooling demands inside the building

- Often paired with adjustable brackets for better airflow control

In sun-drenched cities, these panels aren’t just smart—they’re necessary.

At WALLNOVA, we pride ourselves on our ability to deliver high quality aluminum panels that meet the unique needs of each of our customers. Our comprehensive approach, from project confirmation to after sales support, is designed to provide you with peace of mind and confidence in your choice of WALLNOVA as your aluminum panel supplier. Choose WALLNOVA for your next project and experience the difference that our commitment to quality and customer satisfaction can make.

Don’t settle for less when it comes to your project’s materials. Contact WALLNOVA today to discuss your aluminum panel needs and let us help you bring your vision to life. Together, we can create something extraordinary.

Contact Email:info@wallnova.com