Custom Aluminum Panels Curtain Wall systems aren’t just shiny metal skins slapped on buildings—they’re the armor, the identity, and let’s be honest—the first thing people judge when they roll up to your project site. If you’re wrangling specs for a high-rise or mapping out a sleek civic center, you know this isn’t a game of guesswork. It’s about finding high-quality aluminum panels that work as hard as your crew.

“A poorly chosen alloy can buckle under pressure—literally,” says Kai Ren, senior engineer at Wallnova (2024 Q1 Materials Performance Report). “We see too many projects cut corners early and pay double later on the aluminum facade.”

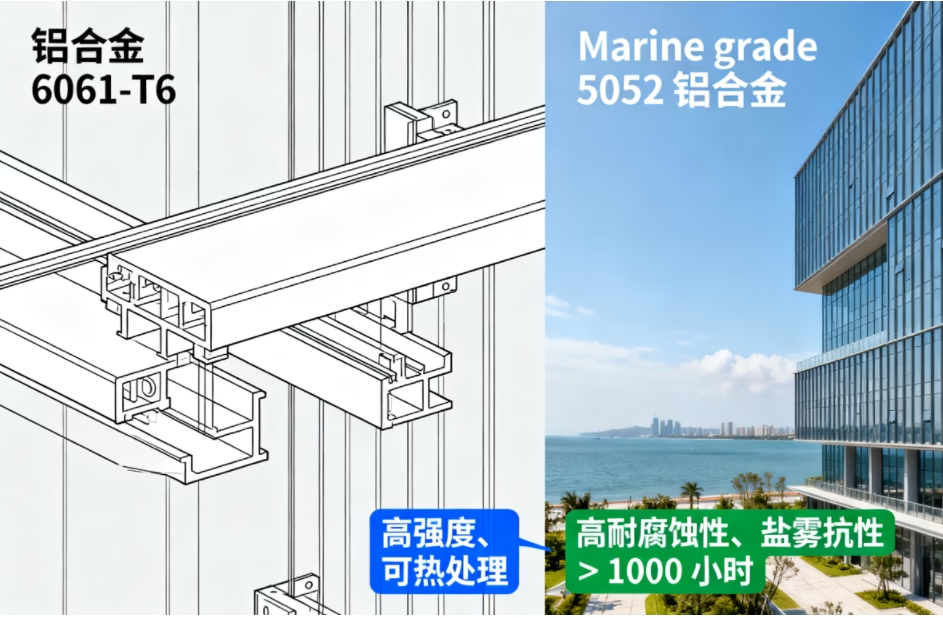

From 6061-T6 aluminum alloy muscle to marine-grade finesse in 5052, picking the right aluminum curtain wall material is like choosing boots before hiking Everest—if they don’t hold up, neither do you.

This quick guide walks you through how to choose custom aluminum panels that check every box: strength, finish options, size flexibility—and yes—even those annoying certifications everyone keeps emailing about.

Key Points to Nail Your Custom Aluminum Panels Curtain Wall Specification

✔️ Choose the Right Alloy: 6061-T6 aluminum delivers strength and versatility, while 5052 aluminum alloy offers top-tier corrosion resistance—especially critical for coastal or humid environments for the external aluminum cladding.

✔️ Customize Extruded Profiles: Tailor structural elements using extruded aluminum profiles to ensure load-bearing performance and aesthetic harmony with your building design.

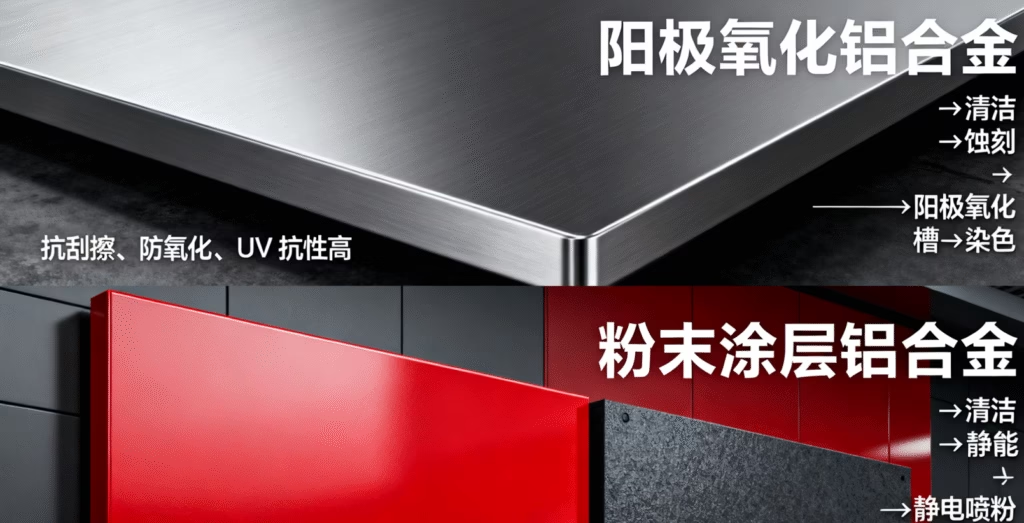

✔️ Select Surface Finishes Strategically: Anodized finishes enhance durability and resist oxidation; powder-coated aluminum surfaces expand color possibilities with a tough, weather-resistant layer.

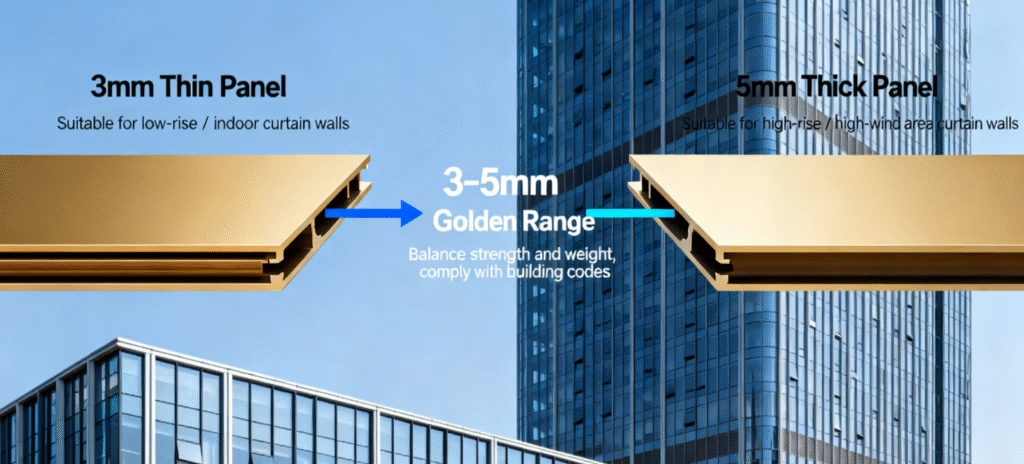

✔️ Get Precision in Panel Dimensions: Aim for aluminum panel thickness between 3–5 mm, width over 1.5 m, and lengths up to 6 m for maximum durability and installation flexibility.

✔️ Balance Beauty with Protection via Coatings: Use PVDF coatings or anodizing when you need both visual appeal and long-term environmental protection for the aluminum facade panels.

✔️ Check All the Certification Boxes Early: Ensure compliance with ISO 9001 quality standards, LEED requirements, fire resistance tests, and ASTM specs before final sign-off for your aluminum building enclosure.

Types Of Custom Aluminum Panels Curtain Wall Alloys

A quick guide on picking the right aluminum alloy for your aluminum curtain wall panel setup—strength, corrosion resistance, and design flexibility all matter.

Aluminum alloy 6061-T6: Overview for Strength and Versatility

- High strength makes it a go-to for large-scale structures and structural curtain wall systems.

- It’s heat treatable, so you can fine-tune performance.

- Offers solid corrosion resistance, even in urban grime.

- Architects love its balance of strength and weight.

- Engineers favor it where structural loads are no joke.

- Fabricators dig how easily it welds and machines.

- Used in both horizontal beams and vertical mullions.

- Great when paired with glass-heavy facades needing rigid support.

It’s not just brawn—this alloy is smart too. Because of its versatility, Aluminum alloy 6061-T6 fits into everything from high-rise aluminum panels curtain walls to complex atrium designs. It holds up under pressure, literally.

Short spans? Long spans? Doesn’t matter much. This aluminum alloy adapts fast, offering clean lines without compromising performance. If you’re after something that won’t back down under weight but still plays nice with finishes, this one’s a keeper for your exterior aluminum cladding.

Marine grade aluminum 5052 Superior Corrosion Resistance

| Grouped Applications & Benefits: | Performance Traits |

| Outdoor Exposure | High corrosion resistance |

| Coastal buildings | Excellent for welding |

| Rain-prone zones | Long-term durability |

| Rooftop cladding | Ideal for coastal aluminum facades |

| Property | Value Range | Unit | Relevance |

| Tensile Strength | 210–260 | MPa | Moderate load-bearing |

| Elongation at Break | 12–20% | Flexibility in fabrication | |

| Density | 2.68 | g/cm³ | Lightweight material |

| Salt Spray Resistance | >1000 | Hours | Ideal for marine climates |

Unlike other alloys that tap out early in salty air, Marine grade aluminum 5052 keeps going strong—especially when those sea breezes bring more than just fresh air. Its anti-corrosive nature makes it ideal for coastal installations where rust is public enemy number one for architectural aluminum panels.

Add the fact that it’s super weldable and you’ve got a reliable option for seamless aluminum panels joints or curved facade elements that need bending without cracking under pressure.

Extruded aluminum profiles Customizable Structural Elements

You want flexibility? This is where things get interesting for the aluminum frame components:

- Need custom shapes? These profiles can be extruded into virtually any geometry—Z-shapes, I-beams, or even wild curves for the curtain wall system.

- Want lightweight but strong framing? Done—extrusions offer both without compromise thanks to their efficient cross-sections.

- Hoping for easy integration with glass panels or insulation layers? These profiles are made with compatibility in mind for aluminum and glass facades.

According to a recent report by Global Construction Insights (2024), “Custom aluminum extrusions now account for over 65% of new curtain wall systems due to their design adaptability and cost efficiency.”

That’s because Extruded aluminum profiles aren’t just about looks—they’re structural workhorses dressed up as sleek design elements. You can tweak them endlessly until they fit your project like a glove—and they’ll still hold firm when the wind hits hard at ten stories up.

From minimalistic modern towers to retrofitted commercial blocks, these customizable pieces keep your options wide open while keeping installation costs tight for your unitized or stick-built curtain wall.

Anodized Vs. Powder-Coated Aluminum Alloys

Quick look at how different surface treatments stack up when it comes to aluminum alloys used in exterior aluminum panels design and fabrication.

Anodized aluminum panels

- Boosts resistance to wear, scratches, and fading—great for high-touch surfaces like window frames or facade panels.

- The electrochemical process forms a thick aluminum oxide layer, not just coating but integrating into the metal itself.

- Offers a sleek metallic sheen with finishes ranging from satin to matte, without adding extra material thickness.

- Highly resistant to UV rays—color doesn’t fade easily even under intense sun exposure.

- Excellent for coastal projects due to superior corrosion resistance against salty air on aluminum cladding.

While not ideal if you’re after bold colors or textured finishes, it’s perfect when durability and clean lines are top priority in your aluminum panels curtain wall design.

Grouped summary:

| Aesthetic | Durability | Best Use Case |

| Sleek metallic hues only; no bright colors. | Exceptional scratch and weather resistance. | Urban towers, minimalist facades, and high-wear areas of custom curtain structures. |

Powder-coated aluminum alloys

Powder coating’s all about color freedom and hardcore protection—it slaps on bold shades while shielding your frame from rust, rain, and grime.

- Applied via an electrostatic application, dry powder clings to the metal before being cured under heat into a seamless shell-like coat.

- That baked-on finish? It’s tough as nails—resists chipping better than most liquid paints.

- You get nearly unlimited color options, including textured effects like sandpaper matte or glossy candy tones for your colored aluminum panels.

| Durability | Visual Appeal | Protection |

| Withstands harsh climates without cracking or peeling | Customizable textures (smooth, rough, hammered) | Excellent UV resistance for exterior PVDF coatings |

| Forms a thicker barrier than anodizing | Wide range of colors for expressive architecture | Shields against acid rain & airborne pollutants |

In modern builds using segmented curtain profiles or modular aluminum paneling systems, powder-coating remains the go-to when you need both pop and protection.

Four Steps To Specify High-Quality Curtain Wall Panels

Nailing the right specs for your aluminum wall system? These four focal points make all the difference when it comes to performance, looks, and long-term value.

Optimal panel thickness 3–5 mm for enhanced durability

Aluminum panel thickness between 3–5 mm hits the sweet spot for strength without overloading the frame.

- Thicker panels (closer to 5 mm) boost resistance in high-wind or seismic zones.

- Thinner options (around 3 mm) work well for low-rise or interior-facing applications.

- Always match thickness with specific building codes and design loads for the curtain wall facade.

Leveraging customized sizes: Width over 1.5 m, length up to 6 m

Bigger isn’t always better—but when you’re working with large-format aluminum panels on a curtain wall, going beyond standard sizing unlocks creative freedom. Custom widths over 1.5 m and lengths stretching up to 6 m mean fewer joints, cleaner lines, and faster installs.

Balancing protection and aesthetics with PVDF, anodized, and color coatings

- Want that sleek look without sacrificing weather resistance? Go with PVDF coating—it shrugs off UV rays like sunscreen for metal.

- Prefer something more industrial? An anodized coating adds corrosion defense while keeping things crisp and matte on the architectural panels.

- Eyeing bold shades or signature branding tones? That’s where durable color coatings come into play—just make sure they’re rated for outdoor exposure.

These finishes don’t just dress up your aluminum—they armor it too. A good PVDF or anodized finish keeps heat out, color locked in, and maintenance way down.

Certification checklist From ISO 9001 to LEED and fire resistance testing

No matter how slick your design is, if it doesn’t pass inspection—you’re toast.

- Start by confirming ISO credentials like ISO 9001, which signals solid manufacturing practices for custom aluminum panels.

- Then check for green cred through LEED-aligned materials—those help earn sustainability points fast.

- Finally—and this is big—test results on fire resistance are non-negotiable for safety compliance in modern facade design.

FAQs about Custom Aluminum Panels Curtain Wall

What’s the ideal aluminum alloy for curtain wall panels in demanding environments?

It depends on where your building stands. If it’s near the coast or exposed to constant humidity, marine-grade 5052 is a solid choice—it resists corrosion like few others can. For projects needing more structural strength, 6061-T6 steps up with its dependable toughness and versatility. And when design freedom matters most, extruded profiles open doors—literally and creatively—with their ability to be shaped into just about anything for your custom aluminum facade.

How thick should custom aluminum curtain wall panels be for real-world durability?

Panels between 3 mm and 5 mm tend to hit the sweet spot: strong enough to handle wind loads and daily wear without becoming too heavy or difficult to install. Thicker options are generally better suited for high-rise buildings or areas with extreme temperature swings.

Can I get custom sizes that actually match my building’s unique shape?

Absolutely—and you should. Aluminum curtain wall panels aren’t one-size-fits-all; architecture isn’t either. With widths beyond 1.5 meters and lengths stretching up to six meters, these aluminum panels adapt instead of forcing your design into a box. Fewer seams mean cleaner lines, faster installation, and less chance of water sneaking through joints down the road.

Why do architects favor anodized finishes so often? Isn’t paint good enough?

Paint fades; anodizing doesn’t flinch under sun or storms. It bonds at a molecular level—no peeling, no chipping—and leaves behind an elegant metallic sheen that feels intentional rather than artificial. Anodizing doesn’t just protect—it elevates aesthetics while standing guard against time itself for your aluminum exterior.