1. Surface Treatment Techniques — Enhancing Appearance and Performance

When you talk about aluminum wall panels, what really makes them stand out is the surface finish. That layer on top isn’t just decoration — it decides how the panels age, how they handle the weather, and how much time you’ll spend keeping them clean. Over the years, I’ve seen a handful of finishing methods pop up again and again. Some are better outdoors, others shine indoors. Here’s a breakdown, with a few lessons I’ve picked up from actual projects.

1.1 Fluorocarbon Coating (PVDF Coating)

If you’ve ever noticed a building façade that still looks crisp after years of rain and sun, odds are it’s PVDF-coated aluminum. This finish is almost a standard for exterior use because it doesn’t fade easily and can handle tough weather.

People in construction circles often say PVDF is worth the extra cost because you won’t be repainting or replacing faded panels a few years later. Personally, I’d call it the “set it and forget it” option — once it’s up, you don’t worry about it for a long time.

1.2 Powder Coating

Powder coating is more of a “day-to-day” option. It’s affordable, it comes in a huge range of colors, and the process itself is relatively eco-friendly. Designers like it when they need to match interiors quickly, like in office ceilings or lobby walls.

That said, I wouldn’t rely on it for a sun-facing exterior wall. UV exposure tends to wear it down faster than PVDF. Indoors though? It’s a reliable, good-looking finish that doesn’t break the budget.

1.3 Anodizing

Anodizing has a different vibe. Instead of coating the surface, it strengthens the aluminum itself through an electrochemical process. The result is a clean metallic look that feels solid and resists scratches better than painted finishes.

I’ve seen anodized panels in busy public spaces hold up surprisingly well — places where people brush against the walls daily. The downside is color variety: you’re mostly working with silvers, bronzes, and darker shades. But if you’re after durability and a classic metal finish, anodizing is tough to beat.

1.4 Electroplating & Mirror Polishing

Electroplating is what you see in showrooms or luxury hotels: shiny, almost mirror-like aluminum that immediately grabs attention. Mirror polishing or brushed finishes fall into the same category — sleek, futuristic, and very design-forward.

The catch? These finishes look amazing but show fingerprints fast. Maintenance teams will tell you they’re constantly wiping them down. So, they work best in spaces where you want the “wow” factor and don’t mind a bit of upkeep.

1.5 Transfer Printing (Wood Grain / Stone Grain)

Transfer printing is for people who love the look of natural materials but don’t want the hassle. Transfer printing lets aluminum mimic wood or stone — everything from walnut to marble — without worrying about cracks or moisture damage.

I’ve seen it used in shopping malls and office spaces where the goal is a warm, organic feel but the designers still want the durability of metal. One tip: always ask to see bigger samples. A small swatch might look great in the catalog but can feel very different once it covers an entire wall.

👉 Quick takeaway:

There isn’t a single “best” finish. It depends on where the panels are going and what you want them to look like after five or ten years. Outdoors? PVDF usually wins. Indoors? Powder coating and transfer printing give you more style choices. For premium durability, anodized or mirror finishes are a solid bet.

2. Shaping & Forming Techniques — Achieving Design Flexibility

When people talk about aluminum wall panels, the finish usually gets all the attention. But in reality, how the panels are shaped can completely change the vibe of a space. A bend here, a pattern there — and suddenly, it doesn’t feel like flat metal anymore. Over time I’ve noticed architects lean on a handful of shaping tricks, each with its own effect.

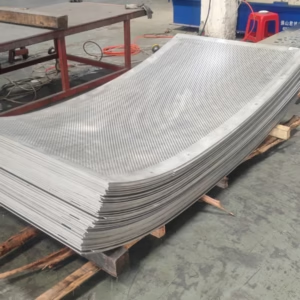

2.1 Bending & Forming

This is the starting point for most projects. Panels get bent into sharp corners or gentle curves depending on what the building calls for. It sounds basic, but it’s what makes aluminum flexible enough to wrap around edges or soften a space.

I once walked into a lobby where the designer had used curved panels overhead instead of flat ones. It wasn’t a huge change on paper, but in person it made the room feel less stiff. Corners can look neat and precise with a simple right-angle bend, while curves give off a more fluid, modern feel.

2.2 Grooving

Grooving doesn’t show up in glossy brochures, but ask any installer and they’ll tell you it matters. Cutting grooves into panels makes folding cleaner, so joints line up and walls look smoother.

Without grooves, folds can bulge slightly, which makes the whole surface feel uneven. With grooves, everything sits flat. It’s one of those “invisible details” that makes the finished wall look professional instead of patchy.

2.3 Perforation

Perforation — punching holes in aluminum panels — might sound purely decorative, but it’s often practical too. Perforated panels can help with airflow, cut down on echo in large halls, or just add texture.

I remember a shopping complex that used perforated walls with lighting behind them. By day, the holes acted as vents; by night, the backlighting turned the whole façade into a glowing pattern. Simple idea, big effect.

2.4 Engraving & Hollow-Out

Laser cutting and CNC engraving take things a step further. Instead of just punching holes, you can carve out custom shapes and patterns. Some hotels even laser-cut their logos into feature walls, so branding is literally built into the space.

In restaurants or cultural venues, engraved panels are often used for artistic motifs — geometric grids, floral patterns, or something abstract that becomes a talking point. It’s less about utility, more about personality.

2.5 Custom Shaped Panels

Flat and rectangular isn’t the only option. Panels can be formed into arcs, triangles, or even irregular polygons. These aren’t everyday choices, but when a building wants to stand out, they work wonders.

Museums and cultural centers tend to love this approach. I’ve seen designs where the façade itself became part of the artwork, with angled panels catching the light differently throughout the day. It’s tricky to design and install, but the result doesn’t blend in — it makes the building memorable.

Takeaway:

Shaping techniques are what give aluminum its design flexibility. Bending and grooving are the fundamentals, perforation adds function and flair, engraving brings artistry, and custom shapes push boundaries. What works best depends on the project: some just need clean corners, others call for a statement wall. The beauty of aluminum is that it can handle both ends of that spectrum.

3. Process Comparison & Selection Guide — Choosing the Right Technique

When you start planning aluminum wall panels, one of the biggest decisions is which process to use. On a catalog page, PVDF, powder coating, anodizing — they all sound good. But in real projects, they behave very differently. I’ve seen designers and builders get it right, and I’ve also seen people regret cutting corners. Here’s how these choices usually play out in practice.

3.1 Fluorocarbon (PVDF) vs. Powder Coating

PVDF is the workhorse for outdoor walls. Once it’s up, it pretty much stays the same for years — sun, rain, pollution don’t bother it much. Powder coating, on the other hand, looks great indoors, and it’s cheaper, but outdoors it can lose color faster than you expect.

What most contractors say is true: PVDF hurts the budget at the beginning, but it saves you repainting costs down the road. Powder coating is flexible with colors — useful if you’re matching an interior theme.

👉 If you’re doing a glass-and-aluminum office tower, PVDF outside and powder-coated ceilings inside is a combo I’ve seen work well.

3.2 Anodized vs. Electroplated Finishes

These two are very different personalities.

Anodized panels feel solid, understated, and can take a beating without showing it.

Electroplated panels scream “luxury” — glossy, reflective, eye-catching.

A busy airport concourse? Anodized holds up way better against luggage bumps and daily wear. A boutique jewelry store? Electroplated panels under spotlights look stunning, even if staff have to wipe them down often.

👉 Pick anodizing when you need toughness; go with electroplating if your goal is to wow visitors the moment they walk in.

3.3 Brushed vs. Mirror Finishes

Brushed panels are subtle. They diffuse light, hide scratches, and keep looking good even when nobody’s polished them in weeks. Mirror panels are the opposite: sharp, shiny, glamorous — but also high-maintenance.

I remember a tech company using brushed finishes in their lobby — the look was modern but not overdone. Contrast that with a luxury store that went full mirror finish; the effect was jaw-dropping under the lights, but the cleaning crew practically lived with microfiber cloths in hand.

👉 Brushed = practical style. Mirror = statement piece (if you can handle the upkeep).

3.4 Perforated vs. Engraved Panels

Perforated panels are clever because they do more than look nice — they can help with airflow or reduce echo in big halls. Engraved panels, on the other hand, are pure design.

I’ve seen malls use perforated panels with hidden lighting, so at night the façade glows like a lantern. Meanwhile, boutique hotels love engraved panels in lobbies — usually with patterns that tie into their brand story.

👉 If you need function and aesthetics together, go perforation. If you just want to create identity and mood, engraving is the way.

3.5 Balancing Cost and Performance

Here’s the honest part: you can’t have everything unless the budget is endless. PVDF and engraving cost more, but they last and make a strong impression. Powder coating is cheaper, but you trade durability.

The smartest projects I’ve seen combine methods:

- PVDF on the sun-facing walls,

- powder coating for less visible indoor panels,

- maybe one engraved feature wall where it really counts.

That way, money is spent where people notice it most.

3.6 Recommendations by Project Type

Office towers: PVDF on the exterior, brushed anodized panels for lobbies.

Retail & hotels: Mirror or electroplated finishes for entrances, powder coating behind the scenes.

Cultural spaces: Perforated panels for airflow, engraved details for identity.

Residential projects: Powder coating or transfer printing — budget-friendly and stylish.

3.7 Quick Checklist Before Choosing

- Indoors or outdoors?

- Will the wall face direct sun or heavy weather?

- Do you want it to look subtle or make a bold statement?

- Is long-term maintenance realistic, or do you need “install and forget”?

- What’s the budget ceiling?

Answer those, and usually only one or two processes make real sense.

Wrap-Up:

There isn’t a “best” process across the board. PVDF is unbeatable outdoors, powder coating makes sense indoors, anodizing is for toughness, electroplating for glamour, brushed finishes are easy-going, mirror finishes demand attention, perforation balances form and function, and engraving turns a wall into a piece of art.

Most successful projects I’ve seen don’t stick to one technique — they mix and match, and that’s what keeps the balance between cost, durability, and design impact.