Abstract:

Aluminium panels have the advantages of rich colour, durability, and diversified appearance and shape, and are widely used in curtain wall projects. Sealant is often used to seal the joints between aluminium panels during the construction of aluminium curtain walls, but sealing failure occurs from time to time. There are many reasons for the sealing failure of aluminium curtain walls, such as irrational design, improper selection of sealant, poor bonding, and improper construction. In this paper, the sealing failure of aluminium curtain walls is analysed and demonstrated, and problem-solving methods are proposed.

Keywords: aluminium curtain wall, sealant, sealing failure, water leakage, cracking

1. Preface

Curtain walls are composed of metal frames and panels, do not bear the main structure’s load, and serve as the building envelope. They have the advantages of aesthetics, energy saving, and ease of maintenance, making them the choice for modern high-rise buildings and shaped structures. The main forms of modern architectural curtain walls include glass curtain walls, stone curtain walls, metal curtain walls, and artificial plate curtain walls. Metal curtain wall panels are selected from aluminium, fire prevention board, stainless steel plate, colour-coated steel, etc. Aluminium curtain walls have the following characteristics:

- Rich colour, long-lasting, diversified appearance and shape, which can be perfectly combined with glass and stone curtain walls through paint spraying processes;

- Light weight, only 1/5 of the stone curtain wall and 1/3 of the glass curtain wall, significantly reducing the weight of the building facade;

- Low maintenance costs and high cost-effectiveness.

Due to these advantages, aluminium curtain walls are widely favoured by building owners. Currently, China’s market for aluminium curtain walls mainly uses aluminium alloy single-layer aluminium panels, aluminium composite panels, and aluminium honeycomb panels.

With the large-scale use of aluminium curtain walls, more and more sealing failures occur. Sealing failure of aluminium curtain walls brings harm to the curtain walls, such as leakage, which can cause destruction of building interiors and corrosion of curtain wall anchors, affecting the safety of the building. Additionally, sealing failure can increase the building’s energy consumption. In this paper, we analyse the common causes of sealing failure of aluminium curtain walls and find effective solutions.

2. Causes of Sealing Failure in Aluminium Curtain Walls

There are many reasons for sealing failure in aluminium curtain walls, including irrational design, improper selection of sealant, poor bonding, and improper construction operations.

2.1 Interface Design and Sealant Displacement Capacity Mismatch

People often find that sealants used in aluminium curtain wall interfaces exhibit cracking phenomena (Figure 1), especially during seasonal changes when the temperature difference between day and night is particularly large. When the temperature drops, the shrinkage of the panels causes excessive stretching of the sealant. This is mainly due to the sealant’s displacement capacity not meeting the actual usage requirements. When calculating the sealant width of the interface, designers should consider factors such as thermal expansion and contraction of the panels, displacement caused by dynamic loads from the floor, and installation errors. The following formula is generally used to calculate the minimum width required for the interface:

Minimum interface width=(X100)×(Mt+Ml)+Tc

Where:

- X: Sealant displacement capacity (%)

- Mt: Displacement due to thermal expansion (mm)

- Ml: Displacement due to dynamic load (mm)

- Tc: Construction error (mm)

Designers need to choose a reasonable displacement capacity for the sealant to avoid cracking caused by insufficient displacement capacity. The sealant’s displacement capacity should also be supported by a report from a national authority inspection centre. In design, it is important to ensure that the sealant forms a two-sided bond rather than a three-sided bond in the interface. When a three-sided bond occurs, the sealant can only withstand about 15% of the designed displacement capacity. For deeper interfaces, PE foam rods should be used to fill and control the thickness of the sealant; for shallower joints, anti-adhesive tape should be used to isolate the sealant from the bottom. Using anti-adhesive tape or PE foam rods can effectively avoid three-sided bonding. Otherwise, the sealant is prone to tearing when subjected to external forces, losing its sealing and waterproofing effects.

Figure 1: Cracking of aluminium curtain wall caused by irrational selection of sealant.

2.2 Improper Selection of Sealant

Currently, there are many sealant products available for weatherproofing and waterproofing, including polyurethane sealant, polysulfide sealant, and silicone sealant. In engineering cases, many people do not pay attention to the differences between these sealants and arbitrarily choose to apply them on aluminium curtain walls, often resulting in sealant surface cracking and chalking phenomena (Figure 2).

Figure 2: Sealant cracking and chalking phenomenon.

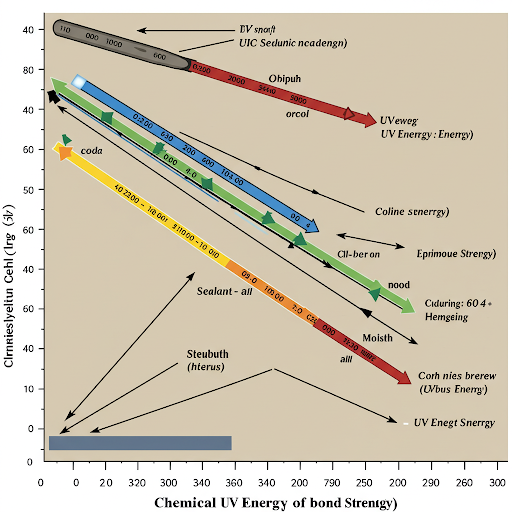

The main chain structure of the base polymer used in silicone sealant is the Si-O bond, while the main chain structure of polyurethane sealant includes C-O, C-C, and C-N bonds, and the main chain structure of polysulfide sealant includes C-S and S-S bonds. Table 1 compares the chemical bond energy of different sealants with the strong ultraviolet energy in sunlight. Except for the Si-O bond, the other chemical bond energies are lower than the energy of 300nm ultraviolet light. This means that silicone sealants can maintain good performance even after long-term exposure to ultraviolet radiation, while other sealing materials may crack and lose their waterproofing function over time.

Table 1: Comparison of chemical bonding energy of different sealants with the energy of strong ultraviolet rays in sunlight.

| Chemical Bond | Bond Energy (kJ/mol) | UV Energy (300nm) (kJ/mol) |

|---|---|---|

| Si-O | 452 | 398 |

| C-O | 358 | 398 |

| C-C | 348 | 398 |

| C-N | 305 | 398 |

| C-S | 260 | 398 |

| S-S | 226 | 398 |

In the selection of sealants for aluminium curtain wall sealing, silicone sealants should be preferred. However, it is also necessary to choose products with guaranteed quality and avoid cheap options that add a large amount of ‘white oil’. While ‘white oil’ is inexpensive and can make the sealant surface appear shiny, it gradually evaporates, causing the gel to harden and crack. The use of silicone sealants should also pay attention to the product’s shelf life. Expired products may lead to adhesive seam bubbling, reduced performance, or failure to cure.

2.3 Poor Bonding

Aluminium curtain walls also often experience poor bonding between the sealant and aluminium. This is due to the different surface treatments of aluminium, such as anodic oxidation, fluorocarbon spraying, and powder coating. Different treatments and manufacturers’ processes can affect the surface structure and performance of the aluminium panels, thereby influencing the sealant’s bonding. If the project does not conduct the required bonding and compatibility tests as specified, the result may be chemical changes between the silicone sealant and aluminium panels or tapes, affecting adhesion and the sealing effect. Therefore, it is necessary to conduct compatibility and adhesion tests for silicone sealants and contact materials in accordance with GB 16776-2005 ‘Silicone Structural Sealant for Construction’ Appendix A and B to ensure system sealing.

During on-site construction, to ensure good bonding between the sealant and the aluminium panel, the following steps must be strictly followed:

- Use the cleaning solvents recommended in the bonding test report. Alcohol solvents may not effectively remove pollutants on polyester powder coating materials.

- Use a two-step cleaning method with a white, clean, soft, absorbent, and non-linting cotton cloth. First, use one piece of solvent-impregnated cotton cloth to wipe, and then use a second piece of clean cotton cloth to wipe.

- The sealant should be applied to fill the entire interface and tightly adhere to the substrate surface that needs to be bonded with the sealant.

2.4 Other Improper Construction Operations

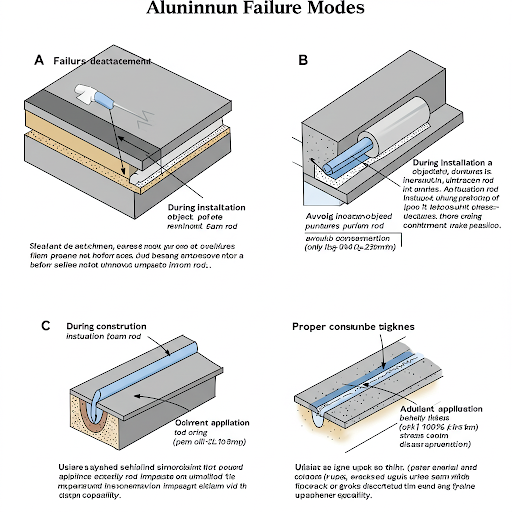

To avoid scratches during the processing and transport of aluminium units, a layer of PE protective film is usually applied to the surface. Therefore, after the installation of aluminium panels, the PE protective film needs to be cleaned before applying glue. If the PE protective film is not cleaned up before gluing, the sealant will only adhere to the PE protective film. With continuous stretching and compression of the sheet joints, a sealant and substrate debonding phenomenon will occur.

Figure 3:

(a) Aluminium plate protective film not cleaned up, causing debonding;

(b) Foam rod damage caused by sealant blistering;

(c) Sealant sizing too thin, causing cracking.

In the sealant sizing process, PE foam rods are usually used to control the sizing thickness. When installing the PE foam stick, it is necessary to prevent it from being pierced by sharp objects (e.g., knives, scrapers, rivets, etc.) to avoid sealant blistering during the curing process (e.g., Figure 3(b)). The construction thickness of the sealant should be controlled at about 6mm. If the glue injection is too thin (2~3mm), it is easy to cause stress concentration, resulting in sealant cracking (such as Figure 3(c)). At the same time, the sealant sizing should not be too thick, as this can significantly reduce the displacement capacity of the sealant. Generally, the construction thickness of the sealant should be 50% to 100% of the actual joint width.

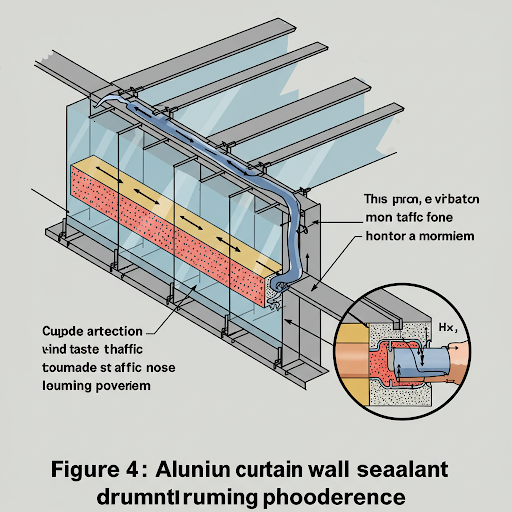

The thermal expansion coefficient of aluminium panels is large. When the temperature difference is significant, the thermal expansion and contraction of the aluminium panels can easily lead to the surface of the sealant bulging before it is fully cured, especially in transverse joints (Figure 4). This “drumming” phenomenon occurs because the sealant is solid inside and does not affect the sealing effect; it mainly impacts the aesthetics of the joints. For this phenomenon, the solution can be to apply the sealant in two applications or during a time when the ambient temperature is more constant.

Figure 4: Aluminium curtain wall sealant drumming phenomenon.

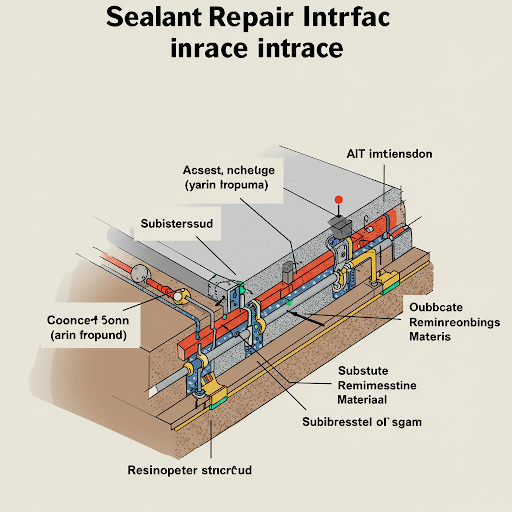

When the sealant cracks and it is not easy to clean up the glue joints, the repair interface design shown in Figure 5 can be used:

- Size A is at least 6mm.

- Size B is at least 3mm.

- Anti-adhesive tape must be used to separate the newly constructed sealant from the failed sealant, so that the repaired sealant can move with the interface.

Figure 5: Schematic design of sealant repair interface.

Conclusion

Aluminium curtain walls have the advantages of rich colour, long-lasting durability, diversified appearance and shape, low maintenance costs, and high cost-effectiveness. They are widely used in curtain wall projects. However, sealing failure is a major problem faced by aluminium curtain walls today. Through the analysis in this paper, joint design, sealant selection, construction quality, and environment are the key factors affecting the perfect sealing of aluminium curtain walls. Adhesion tests should be carried out before applying the sealant, and construction personnel should operate according to the standard construction process. After construction is completed, on-site sampling and cutting experiments should be conducted to ensure that the sealant meets the requirements of the design drawings and bonds well with the substrate, ensuring that the entire aluminium curtain wall system is well sealed.