- Material Properties (Performance)

Lightweight and highly weather-resistant: Coated with fluorocarbon spray, polyester paint, or epoxy resin paint to withstand UV exposure, maintain color integrity over time, and ensure a long service life.

Excellent self-cleaning and stain-resistant properties: Resists oil and water, and prevents contamination.

Good processability: Uniform coating with a wide range of color options.

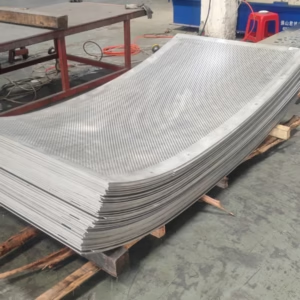

Versatile shaping capabilities: Can be processed into complex shapes.

Environmentally friendly: Free from harmful substances.

Excellent adhesion and flexibility: Resistant to scratches and capable of withstanding strong impacts.

High flatness: Especially suitable for curved and irregularly shaped products, with low requirements for the base surface (no need for leveling) and good planar stability.

Easy installation and maintenance: Convenient to install, low maintenance costs, and simple upkeep

2. Product Types (Category)

(1) Classification by Manufacturing Method

Film-coated mirror-finished aluminum panels

Anodized mirror-finished aluminum panels

Polished mirror-finished aluminum panels

Ultra-mirror-finished aluminum panels

(2) Surface Treatment Processes

Spray coating: Different spray coating and drying processes are used based on mirror finish requirements; the surface must be uniform to be suitable for finished product production.

Anti-oxidation polishing treatment: Addresses issues of reduced mirror performance, adapts to different usage environments, and enhances cleaning convenience.

3. Construction Process and Precautions (Technic)

(1) Production Process

1.Install edge trim at the same horizontal height.

2.Configure different frames and structural components according to requirements.

3.Attach the pre-installed hangers on the triangular beams to the light steel beams vertically, and install them sequentially.

4.Secure the horizontal beams to the main structural wall. The spacing between beams is determined by the size of the panels, and the system is leveled after installation.

5.Snap the pre-installed suspension brackets on the panel beams into the connection slots of the light steel beams.

6.Install sealing strips around the edges of each panel.

7.Check flatness, package in sections, and transport to the site for installation.

(2) Construction Precautions

1.Inspect the installation area before laying out the lines.

2.Secure the frame connection brackets.

3.Mark the frame positions on the base layer.

4.Begin securing the frame from one end.

5.Connect the pipes and secure the support brackets.

6.Clean the construction site.

7.Conduct concealed work inspection.

8.Re-inspect.

9.Pour concrete and cure.

10.Finished product protection and final acceptance.

4. Application Cases (Application Case)

(1) Application Fields

Lighting fixture reflectors, solar thermal reflective materials, indoor and outdoor architectural decoration, appliance panels, electronic product housings, furniture and kitchenware, automotive interior and exterior decoration, signage and labels, luggage, jewelry boxes, etc.

(2) Classic Cases

Shanghai Yunhui Tian Di Skywalk

Copper-colored mirror-finished aluminum panels were used to enhance visibility along the elevated structure. At night, when the light rings illuminate, they create a “floating among the clouds” effect.

Actual photo © Shan Jian Imaging

Nanning Shuangding Waste-to-Energy Power Plant

The facade consists of aluminum panel curtain walls and glass curtain walls, with mirrored and matte grilles arranged alternately to create a reflective rhythm. Parametric design achieves a three-dimensional curved surface effect.

Actual photo © Zhiyi Architectural Photography, UUA Architects

Japan SHIKISM Commercial Complex

The colored mirrored aluminum panel facade blends into the commercial street, with balconies of varying sizes and shapes reflecting activities inside and outside the building, fostering interaction between architecture and materials.

Actual photo © Takumi Ota Photography

Chongqing Longfor Yunyao Yubai Demonstration Area

The bottom box uses black mirrored aluminum panels, reflecting tree branches under light and shadow, creating a soft dialogue with the external space.

Actual photo © Prism Space Photography

Shenzhen Nantou Ancient City if Factory

The interior of the grand staircase features mirrored stainless steel and neon signboards, with neon lights reflecting off the mirrored surfaces, echoing the early street market ambiance of Shenzhen.

Actual photo © Xia Zhi

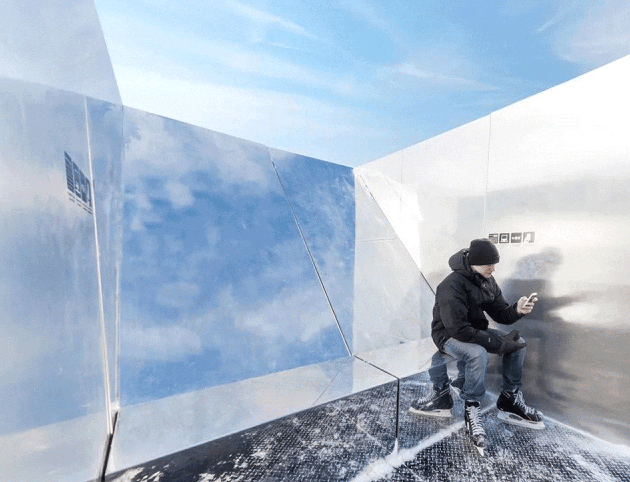

Canada Skybox Installation

45-degree mirrored aluminum panels reflect the sky, folded into a bench, while vertical mirrored aluminum panels project images of visitors and clouds.