The Processing Technology, Quality Assurance Measures, and Handover Acceptance of Curtain Wall Profile Bending

1. Processing Techniques for Bending Curtain Wall Profiles

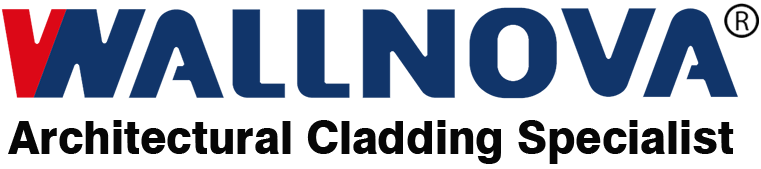

1.1 Material Selection

- Lightweight, high-strength aluminum alloy materials are typically selected due to their excellent corrosion resistance and shape stability, making them suitable for bending processing.

1.2 Bending Equipment and Technology

- Specialized bending equipment, such as CNC machines, is used to enhance processing precision and efficiency. During the bending process, precise calculations and adjustments are made based on design drawings to ensure the bending degree and angle of the profiles meet requirements.

1.3 Process Parameter Control

- This includes mold design, temperature control, and adjustment of bending speed to minimize stress concentration, prevent deformation, and avoid cracks.

1.4 Surface Treatment

- After bending, the surface of the profiles is treated to enhance corrosion resistance and aesthetic appeal.

2. Quality Assurance Measures

2.1 Equipment and Measuring Instrument Management

- Processing equipment and measuring instruments must be regularly inspected and calibrated to ensure processing accuracy.

2.2 Mold Design and Optimization

- Molds must be reasonably designed to prevent deformation or cracking of the profiles during the bending process.

2.3 Strict Control of Process Parameters

- Through testing and experience accumulation, optimize the bending process parameters, such as bending radius, tensile force, etc., to minimize springback and dimensional deviations.

2.4 Surface Quality Monitoring

- Perform surface treatment on molds and use lubricants to prevent scratches and indentations.

2.5 Segmented Bending and Support Fixation

- For large or complex profiles, adopt segmented bending methods and use support fixation techniques to reduce deformation stress.

3. Handover and Acceptance

3.1 Visual Inspection

- Inspect the surface of the profiles for defects such as cracks, wrinkles, or scratches to ensure their appearance is intact.

3.2 Dimension Measurement

- Use measuring tools to measure critical dimensions such as length, angle, and curvature radius to confirm compliance with design requirements.

3.3 Bending Strength Test

- Evaluate the deformation behavior and stress levels of the profiles during the bending process to ensure their bending strength meets requirements.

3.4 Impact Test

- Evaluate the ductility and impact resistance of the profiles to ensure they are unlikely to break or be damaged during actual use.

3.5 Digital Inspection

- Use 3D scanning technology to inspect the profiles, capturing surface contours and deformation conditions to improve processing accuracy and pass rate.

4. Common Issues and Solutions

4.1 Wrinkling and Cracking

- Address these issues by adjusting the mold shape, increasing tensile force, and optimizing process parameters.

4.2 Cross-sectional Deformation and Springback

- Design molds reasonably, use support fixation methods, estimate springback quantities, and apply compensation.

4.3 Surface Scratches

- Perform surface treatment on molds, use lubricants, and strengthen operational monitoring.

4.4 Dimensional Accuracy Issues

- Strictly control process parameters, regularly inspect molds, and strengthen dimensional inspections.

5. Conclusion

The processing technology for curtain wall profile bending requires strict control from multiple aspects, including material selection, equipment management, and process parameter control, to ensure processing quality and precision. Additionally, through digital inspection and quality control methods, the product’s and reliability can be further enhanced. During the handover and acceptance phase, inspections must be conducted in strict accordance with relevant standards and specifications to ensure the profiles meet design requirements and usage standards.