Overview of the U.S. Architectural Curtain Wall Market

Market Size and Growth Trends

- Global Perspective: The global architectural glass curtain wall market reached $52.11 billion in sales in 2024 and is expected to increase to $64.28 billion in 2031, at a compound annual growth rate (CAGR) of 3.1% (2025-2031).

- North America: The U.S., as the core region, continues to grow in the curtain wall market, driven by the application of advanced materials and the demand for energy efficiency. The global curtain wall market is expected to grow at a CAGR of 7.8% from 2024-2029, with a significant market share in North America.

- Segmentation: Commercial buildings (such as super-high-rise office buildings) and public buildings (such as airports and hospitals) are the main application scenarios for curtain walls, with glass and aluminum as the two mainstream materials.

Technology Drivers

- Material Innovation:

- High-strength aluminum alloy (e.g., 6000/7000 series) replaces traditional steel, taking into account lightweight and load-bearing capacity.

- Composite materials (e.g., aluminum honeycomb panels) to improve thermal and acoustic insulation performance, to meet the needs of extreme climate.

- Energy-saving Technology:

- Ventilated curtain walls reduce air-conditioning energy consumption through heat exchange and have become the mainstream of the market.

- Smart glass (e.g., electrochromic glass) dynamically adjusts light transmittance to optimize the indoor environment.

- Digital Design:

- BIM technology runs through the whole process of design, production, and construction, improving efficiency and reducing errors.

- Parametric design supports the accurate landing of complex curved surfaces and shaped curtain walls.

Advantages of Aluminum Curtain Wall

- Lightweight: The density of aluminum alloy is only 2.7g/cm³, which significantly reduces the building load, especially suitable for high-rise and large-span structures (e.g., Shanghai Center Tower, Beijing Daxing Airport).

- Corrosion Resistance and Durability: The surface is anodized or fluorocarbon sprayed, with a weather resistance of 20-30 years, resisting acid rain, UV rays, and salt spray erosion.

- Recyclability: Aluminum recycling rate is over 90%, full life cycle carbon emissions are lower than steel, in line with green building standards.

- Design Flexibility: The extrusion process supports the customization of complex cross-sections, enabling artistic designs such as curved surfaces and openwork (e.g., Museum of the Future in Dubai, Ginza Plaza in Tokyo).

Wallnova Custom Aluminum Curtain Wall Manufacturer

Technical Advantages

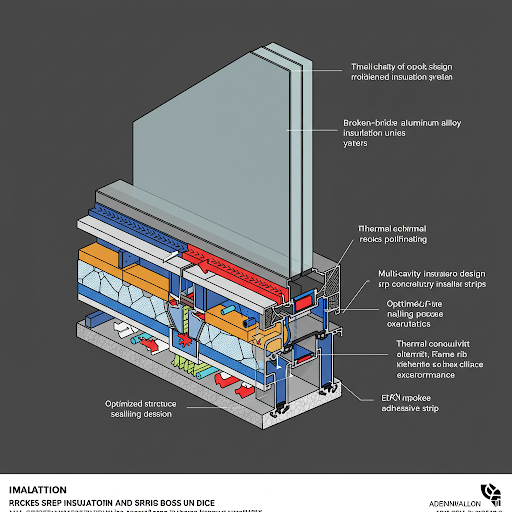

High-performance Insulation System

- Material Innovation: The use of broken-bridge aluminum alloy profiles with insulating glass, combined with thermal bridge blocking technology (e.g., multi-cavity insulation strip design) to effectively reduce heat transfer. Some system windows use recycled polyamide insulation strips, combining environmental protection and thermal insulation performance (thermal conductivity as low as 0.12W/m-K).

- Structural Design: By optimizing the frame structure and sealing process, the air leakage rate is reduced and the overall thermal insulation performance is improved. For example, the use of foam adhesive + nylon rib + EPDM composite adhesive strip ensures the stability of sealing under extreme climate.

Intelligent Curtain Wall Technology

- Integrated Function: Developing a hot-channel curtain wall system that combines double-glazing and intelligent ventilation facilities to optimize energy consumption in winter and summer. The thermal chimney effect is utilized to reduce air conditioning loads in summer, and the inner curtain wall surface temperature is raised in winter to reduce heating energy consumption.

- Monitoring and O&M: Deploying sensors and drone inspection technology to monitor the status of the curtain wall in real time (e.g., displacement, deformation), and combining with BIM modeling to carry out predictive maintenance to improve the efficiency of safety management and response.

Customized Service Capability

BIM Integration and 3D Modeling

- Full-process Collaboration: BIM tools such as Revit are used to realize the integration of design, processing, and construction, and support modular prefabrication and rapid on-site installation. For example, optimizing the construction of complex nodes through BIM parametric design ensures the accurate landing of curved, slanted, and other shaped curtain walls.

- Case Application: Providing a curtain wall solution combining ceramic panels and glass for the K11 ECOAST project in Shenzhen, optimizing the material layout and construction process through BIM simulation.

Rapid Prototyping

- Iterative Development: Shorten the design cycle by adopting the process of “low-fidelity prototype-user feedback-high-fidelity optimization.” 3D printing technology is utilized to produce node samples to verify structural strength and installation feasibility.

- Digital Pre-assembly: Virtual simulation to verify the joints and overall flatness of the unit panels, reducing the rework rate on site.

Certifications and Standards

AAMA Certification

- Product Testing: Certified to AAMA 2605-20 standards, focusing on verifying weathering resistance (e.g., salt spray corrosion, chalking test) and film thickness uniformity. For example, the product has been subjected to cyclic salt spray testing without significant rusting or peeling of the coating.

- Factory Audit: We accept AAMA’s factory inspection twice a year to ensure that the production process complies with the standard and to guarantee product traceability.

ASTM Standard

- Material Performance: Aluminum alloy profiles comply with ASTM standards for mechanical property testing (e.g., tensile strength, yield strength) to ensure structural safety.

- Process Compliance: Processing follows ASTM standard specifications, such as welding process certified by EN1090 to guarantee the reliability of node connections.

LEED Certification Support

- Green Materials: The use of highly recyclable aluminum (recycling rate of over 90%) and low-carbon production process helps the project to obtain LEED material score.

- Energy-saving Design: By optimizing the thermal performance of the curtain wall (e.g., U-value ≤ 1.5W/m²-K), the building energy efficiency is improved to meet LEED energy and atmosphere targets.

Customization and Innovation

Customized Design Process

The whole process from customer demand to product delivery.

Design Consultation

- Requirements Communication: Manufacturer and client engage in in-depth communication to clarify building functions, style preferences, budget constraints, and sustainability goals.

- Technical Feasibility Analysis: Evaluate complex shapes (e.g., curved, slanted), material selection (e.g., high-strength aluminum alloy, glass), and installation conditions (e.g., ultra-high-rise wind-pressure resistance requirements).

Material Selection

- High-performance Aluminum Alloy: 6000/7000 series alloys are selected, taking into account strength and lightweight, suitable for large-span structures.

- Surface Treatment: Fluorocarbon spraying or anodizing to enhance weather resistance and corrosion resistance.

- Sustainable Materials: Recyclable aluminum and recycled materials are used to reduce carbon footprint.

Processing & Installation

- Digital Production: BIM technology is used to generate processing drawings, which are combined with CNC machine tools to achieve accurate cutting and assembly.

- Modular Installation: The unitized curtain wall is prefabricated in the factory and lifted on site, shortening the construction period and reducing construction errors.

Case Study: Complex Project Solution

K11 ECOAST, Shenzhen

- Project Challenge: Integration of art, business, and sustainable design, the curtain wall contains multiple forms such as curved surface, inclined surface, and hollow surface.

- Technological Innovation: BIM parametric design is applied to optimize the node structure, and ceramic panels are combined with glass to achieve the complex façade effect.

Jiaxing Nanhu Future Plaza

- Project Challenge: Double-curved shaped roof, nearly a thousand forms of intersection between ceramic tile curtain wall and main structure.

- Solution: Optimize the installation precision through 3D scanning and digital simulation, and introduce intelligent measurement and deviation correction technology.

Technological Innovation

New Aluminum Alloy Materials

- High-strength Alloys: Such as Alcoa A210 Extru Strong™, with a 40% increase in strength and better anodizing, suitable for thin-walled structural components.

- Optimized Weather Resistance: Ason cast thermal insulation profiles with a thermal conductivity of only 0.12W/m-K, suitable for passive buildings.

Intelligent Curtain Wall System

- Integrated Functions: Photovoltaic power generation, sensors (monitoring temperature and humidity, wind speed), automation control (sunshade louvers, ventilation system).

Brand Case

- Control4: Provides whole-house intelligent control, integrating lighting, security, and HVAC systems.

- Crestron: Focuses on integrated technology solutions that support AV, shading, and building management system (BMS) integration.

Sustainable Design

- Circular Economy: Elicc Group adopts local manufacturing and modular design to extend the service life of curtain wall and reduce material waste.

- Low Carbon Practice: Optimize the thermal performance of curtain walls (e.g., aluminum thermal break) to reduce building energy consumption; apply recycled aluminum to reduce carbon emissions.