Advantages of Aluminum Curtain Wall

Aluminum Curtain Wall has unique advantages. After installation, the texture is unique, the color and lustre is rich, lasting, and the appearance of the shape can be diversified. It can be perfectly combined with the glass curtain wall materials, stone curtain wall materials. Its perfect appearance, excellent quality, make it doubly favored by owners. Its light weight, only one-fifth of the marble, is one-third of the glass curtain wall, substantially reducing the building structure and foundation load, and low maintenance costs, high performance to price ratio. On the current domestic use of curtain wall aluminum, the vast majority of composite aluminum and aluminum alloy veneer.

Composite Aluminum Introduction

Composite Aluminum Composition

Composite aluminum is inside and outside the two layers of 0.5mm pure aluminum (indoor use for 0.2 ~ 0.25mm) intermediate sandwich for 3 ~ 4mm thick polyethylene (PE or polyvinyl chloride PVC) rolled and heat bonded, commodities for a certain specification of the flat plate, such as 1220mm x 2440mm. external composite aluminum surface of fluorocarbon paint is also in the form of rollers with roller coating and rollers, heat bonded at one time. Completed, the thickness of the coating is generally about 20μm.

Advantages of Composite Aluminum Panels

The advantages of composite aluminum panels are lightweight, smooth surface, good flatness, no color difference in the same direction, and has excellent on-site processing. It can deal with on-site construction errors caused by changes in the size of the exterior wall, and provides conditions for reducing the workshop processing cycle and shortening the installation period.

Installation Process of Composite Aluminum Plate Sheet

Composite aluminum plate sheet in the installation to be processed into wall panels. First of all, according to the secondary design of the size of the cut plate, cut the plate to take into account the size of the folded edges plus put, generally about 30mm on each side. According to the curtain wall installation company, cut the plate into the material rate is generally 60% to 70%. Cut composite panels need to be four-sided planing groove, that is, cut off a certain width of the inner layer of aluminum and plastic layer, leaving only 0.5mm thick outer layer of aluminum, and then folded edges into a 90-degree angle, and then use aluminum profiles to make the same size of the pay frame, placed in the Aluminum Composite Plate curved groove, the bottom surface of the pay frame with structural adhesive and Aluminum Composite Plate bonded to the back side, folded up the four sides of the form of rivets fixed to the pay frame on the outside. The pay frame is generally also a middle of the reinforcing bars to Ensure the mechanical strength of the wall panels, reinforcing bars for aluminum, bonded with structural adhesive. Some informal practices only in the four corners of the composite panel plus angle aluminum fixed, reinforcing bars bonded with double-sided tape, its firmness greatly reduced.

Curtain Wall Aluminum Treatment Process

There are two methods for the treatment process of curtain wall aluminum, one is anodic oxidation, the other is electrostatic spraying.

Anodic Oxidation

Anodic oxidation of the oxide film is generally more than 12μ, the color is only bronze and white two, monotonous color. The more serious drawback is that the color of each aluminum plate plate surface is not the same color. Many pieces of curtain wall panels together to form a curtain wall overall effect is very difficult to see. This shortcoming can be said to be unable to eliminate, is not caused by production technology, but because the aluminum plate is not by a batch of number, chemical composition, there are small differences, coupled with oxidation of the electrolytic tank liquid current density and other factors can not be exactly the same, so the oxidation of the color of the color of the more or less differences, a single look may not be obvious, if they are all lined up together, that is, very obvious. So aluminum curtain wall aluminum surface treatment, never use anodic oxidation.

Electrostatic Spraying

Curtain wall aluminum surface treatment is another method of electrostatic spraying. Spraying is divided into powder spraying and liquid spraying. Foam spraying materials are mainly: polyurethane, poly expansion resin, epoxy resin and other raw materials with high color retention pigments, can get dozens of different colors of spray foam. The spray foam, impact resistance, abrasion resistance, in 50 kg impact, aluminum plate deformation, spraying layer without cracks, no drop layer intact, resistant to dilute acid and mortar. The only disadvantage is afraid of ultraviolet radiation for a long time, a few years later, it is easy to produce the difference between the color of yin and yang surfaces. Many domestic manufacturers produce spray foam, the weight difference is very large, some of the foam contains gold chips this foam in the wall after hanging, with the sun angle changes, day and dusk there are changes in the wall color shades of difference, the choice of foam spray paint Hsi caused by attention.

Aluminum Alloy Veneer Introduction

Aluminum alloy veneer is generally 2 ~ 4mm aluminum alloy plate. In the production of wall panels, the first according to the requirements of the secondary design of sheet metal processing, direct folding, four corners of the high-pressure welding into a dense groove, the back of the wall panels with welding planting nails in the way of the reinforcement reinforcement of the fixing bolts are reserved. After the completion of sheet metal work, and then fluorocarbon paint spraying, generally two coated three coated, film thickness of 30 ~ 40 μm. aluminum alloy veneer is easy to processed into curved and multi-folded edges or sharp corners, to adapt to today’s ever-changing need for exterior wall decorations, and rich in color, according to the design and the owners of the requirements of any color, the real sense of the architects to broaden the design space.

Curtain Wall Aluminum Plate and Composite Panel Performance Comparison

1. Material

- Composite aluminum plate: Two layers of 0.5mm thick pure aluminum plate in the middle of the sandwich PVC or PEC plastic roller pressing, heat bonding and become.

- Aluminum alloy veneer: 2 ~ 3mm aluminum alloy plate.

2. Fluorocarbon coating

- Composite aluminum plate: One-time roller printing, coating thickness is generally 20μm.

- Aluminum alloy veneer: 2 or 3 times spraying is completed, coating thickness is generally 30 ~ 40μm.

3. Color

- Composite aluminum plate: Choice of color varieties less, generally more gray, specific colors need to order a large number of single processing, difficult to achieve. Color homogeneity is good, but there is directionality, reducing the rate of material.

- Aluminum alloy veneer: According to the design and the owner’s requirements of any color selection.

4. Life

- Composite aluminum panels: About 10 years.

- Aluminum alloy veneer: Can be more than 50 years.

5. Airtight

- Composite aluminum plate: Four corners of the opening shape.

- Aluminum alloy veneer: Four corners of the welded closure.

6. Wind resistance

- Composite aluminum panels: Poor resistance to wind pressure and deformation.

- Aluminum alloy veneer: Wind deformation resistance is good.

7. Resistance to temperature change

- Composite aluminum plate: Aluminum and plastic expansion coefficient difference is large, easy to blistering, peeling phenomenon.

- Aluminum alloy veneer: The same material, temperature change when the wall itself has no effect.

8. Lightning resistance

- Composite aluminum panels: Not resistant to lightning strikes, strong current is difficult to ground through the composite aluminum panels, 0.5mm thick aluminum panels will be pierced.

- Aluminum alloy veneer: Can be used as a good conductor of electricity, through the building grounding system to lightning strikes huge currents quickly transported to the ground.

9. The shape of wall panels

- Composite aluminum panels: Due to the limitations of the material, suitable for processing simple shapes, not suitable for folding yin corner, <90 ° of the bend easy to break .

- Aluminum alloy veneer: Easy to process into shaped panels, bending angle range.

10. Processability

- Composite aluminum panels: Can be processed on-site, can cope with the dimensional changes brought about by on-site construction errors.

- Aluminum alloy veneer: Production plant production, to adapt to the site of the building error poor, high requirements for the secondary design.

11. Into the material rate

- Composite aluminum panels: Generally 60% to 70%.

- Aluminum alloy veneer: 100%.

12. The rate of finished

- Composite aluminum plate: Site manual operation planing groove, if the depth of the groove is not well controlled, it will hurt the outer layer of aluminum, so that the bending fracture, resulting in scrap, the rate of finished products is generally 96% to 98%.

- Aluminum alloy veneer: Production plant production, factory yield is 100%.

13. Construction quality

- Composite aluminum panels: As the wall panels are mostly on-site processing, poor quality control conditions, jerry-building, substandard situation is prone to appear in this link, the quality of wall panels will affect the quality of construction.

- Aluminum alloy veneer: The production plant according to international standards to control the quality of production, reliable quality of wall panels, providing the premise of ensuring the quality of construction.

14. The scope of application

- Composite aluminum panels: For facade decoration, elevated corridors, footbridges, low-level curtain walls.

- Aluminum alloy veneer: Applicable to high-level curtain wall and large-area curtain wall.

15、Environmental protection

- Composite aluminum panels: High temperature will produce harmful gases, not fireproof, not easy to recycle.

- Aluminum alloy veneer: Fireproof, easy to recycle, do not pollute the environment.

Aluminum (composite) panel curtain wall construction program

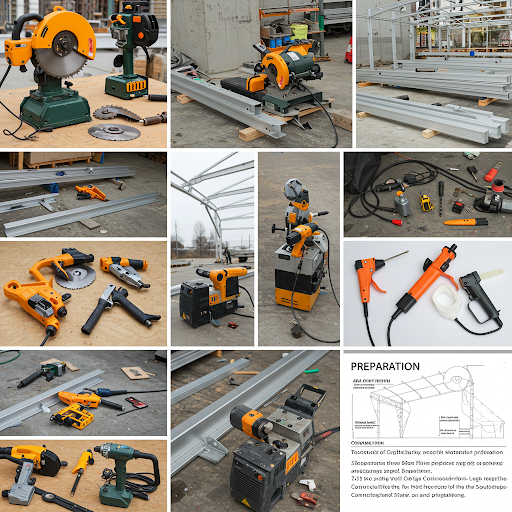

1 Curtain wall tools and equipment used

Toothless saw blade cutting machine, hand drill, impact drill, nail gun, various specifications of drilling flowers, wrenches, screwdrivers, hand hammers, ink line, line pendant, nylon line, steel tape measure, welding machine, oxygen cutting equipment, subject to suction cups, electric crane blue, glue gun, wind pull riveting gun, safety belts and so on.

2 Preparation work before material entering the site

This part of the work is the starting stage of the project, we should serve for the principle of construction, on schedule, quality and quantity, as follows:

Designers need to be in the contract, according to the architectural drawings of the project and the curtain wall project program diagrams, in the shortest possible time to put forward the project’s material plan table.

Project Manager Department and Production Department cooperate with each other, according to the construction schedule and the actual situation of the project site to make the project’s processing plan, reasonable organization and arrangement of production, to ensure timely arrival of products.

the installation process

Line → fixed skeleton of the connectors → fixed skeleton → installation of aluminum plate → closing structure processing → inspection

installation considerations

- Aluminum varieties, quality, color, pattern, line should be in line with the design requirements, and there should be a certificate of conformity of the product.

- Curtain wall wall skeleton, such as the use of steel keel, its specifications, shape should meet the design requirements, and should be descaled, rust treatment.

- Aluminum plate installation, when the design does not require, it is appropriate to use core aluminum rivets, the middle must be padded rubber ring. The spacing of core rivets to control the 100-150mm.

Laying line

Fixing skeleton, the position of the skeleton will be popped up to the grass-roots level. The skeleton is fixed on the main structure and the quality of the main structure is checked before placing the line.

Fixing the connectors of skeleton

Weld the connectors to fix the skeleton on the columns of the main structure.

Fixing the skeleton

The skeleton is pre-treated against corrosion. Install the skeleton in an accurate position and combine it firmly. Check the centerline and surface elevation after installation. In order to ensure the installation accuracy of the board, it is appropriate to use the latitude and longitude of the beam vertical frame bars through. Deformation joints, settlement joints, variable cross-section at the appropriate treatment, so that it meets the requirements of use.

Installation of aluminum plate

The installation of aluminum plate should be firmly and reliably fixed, simple and easy to carry out.

- The gap between the plate and the plate should be processed internally to make it flat and smooth.

- Aluminum plate installation is complete, in the parts that are easy to be contaminated, covered with plastic film or other materials to protect.

aluminum canopies construction program

Aluminum canopies used tools and machinery

Toothless saw blade cutter, hand drills, impact drills, nail guns, various sizes of drilling flowers, wrenches, screwdrivers, hand hammers, ink lines, wire drape, nylon line, steel tape measure, welding machine, oxygen cutting equipment, glue injection gun, wind-operated pull riveting gun, safety belts and so on.

the preparatory work before the entry of materials

This part of the work is the starting stage of the project, to serve for the principle of construction, on schedule, quality and quantity, as follows:

Designers need to be in the contract, according to the project’s architectural drawings and the curtain wall project program diagrams, in the shortest possible time to put forward the project’s schedule of materials used.

The project manager department and the production department cooperate with each other, according to the construction schedule and the actual situation of the project site to make the processing plan of the project, reasonable organization and arrangement of production, to ensure that the products arrive in time.

the installation process

Set up scaffolding → line → fixed steel connectors → welding steel skeleton → installation of aluminum panels → closing structure processing → inspection

the installation of notes

- Aluminum varieties, quality, color, pattern, line should meet the requirements of the design, and there should be a certificate of conformity of the product.

- The canopy steel skeleton specifications, shape should meet the design requirements, and should be rust, rust treatment.

- Aluminum installation, when the design does not require, it is appropriate to use core aluminum rivets, the middle must be padded rubber ring. The spacing of core rivets to control the 100-150mm.

Laying line

Fix the steel skeleton, the position of the skeleton will be popped to the grass-roots level. The skeleton is fixed on the main structure and the quality of the main structure is checked before placing the line.

Fixing the connectors of skeleton

Weld the connectors to fix the skeleton on the columns of the main structure.

Fixing the skeleton

The skeleton is anticorrosive treated after welding. Install the skeleton in an accurate position and combine it firmly. Check the centerline and surface elevation after installation. In order to ensure the installation accuracy of the board, it is appropriate to use the latitude and longitude of the beam vertical frame bars through. Deformation joints, settlement joints, variable cross-section at the appropriate treatment, so that it meets the requirements of use.

Installation of aluminum plate

Aluminum plate should be firmly and reliably installed and fixed, simple and easy to use.

- The gap between the plate and the plate should be processed internally to make it flat and smooth.

- Aluminum plate installation is completed, in the parts that are easy to be contaminated, covered with plastic film or other materials to protect. Composite aluminum curtain wall function more belongs to the building exterior decoration and peripheral protection type, that is, the building itself has an ordinary brick wall or other types of walls. The composite aluminum curtain wall installed outside in addition to its own decorative effect on the building, but also on the building to play the role of perimeter protection. Such aluminum curtain wall itself requires good wind pressure, watertight, airtight performance and weatherproof sealing system.

Composite aluminum curtain wall in the production and installation before the architectural design and construction plans should be checked, and should be measured for the building, according to the measured results of the original design adjustments can be processed and assembled. Processing curtain wall components used in the equipment, machinery should be able to meet the requirements of the curtain wall components processing accuracy, the gauge should be regularly measured and verified.