Choosing metal facade cladding panels isn’t just design—it’s survival. Pick right, and your building laughs at rust for decades.

You’ve got steel bones in your building, but what’s its skin saying to the world? Choosing the right metal facade cladding panels isn’t just about curb appeal—it’s a high-stakes decision that can make or break your project’s budget, timeline, and durability. Too thin and you’re looking at dents from a rogue lawn chair during a windstorm; too thick, and you’re hauling unnecessary weight up ten stories with zero payoff.

There’s no cheat sheet here—just smart decisions backed by specs, weather data, finish chemistry, and real-world wear-and-tear. Aluminum might cost more than steel upfront, but it pays dividends when rust doesn’t rear its ugly head five years down the line.

If you’re sourcing thousands of square feet for exteriors that need to last decades (and still look good doing it), this guide is your shortcut past costly mistakes. Buckle in—we’re talking thickness gauges, fire ratings, rain screens…all the things no one warned you were mission-critical until they were.

Essential Insights on Metal Facade Cladding Panels

Panel Specifications: Metal facade cladding panels come in various specifications, including thickness, dimensions, and profile options that impact both aesthetics and functionality.

Material Properties: Key properties such as corrosion resistance, fire ratings, and thermal expansion are vital for ensuring long-lasting performance and structural integrity.

Surface Finishes: The choice between anodized finishes, powder coatings, and PVDF coatings affects both the appearance and resilience of the panels against weather conditions.

Installation Systems: Different installation systems like rainscreens and concealed fasteners enhance weatherproofing and the overall look of the cladding, influencing project design and execution.

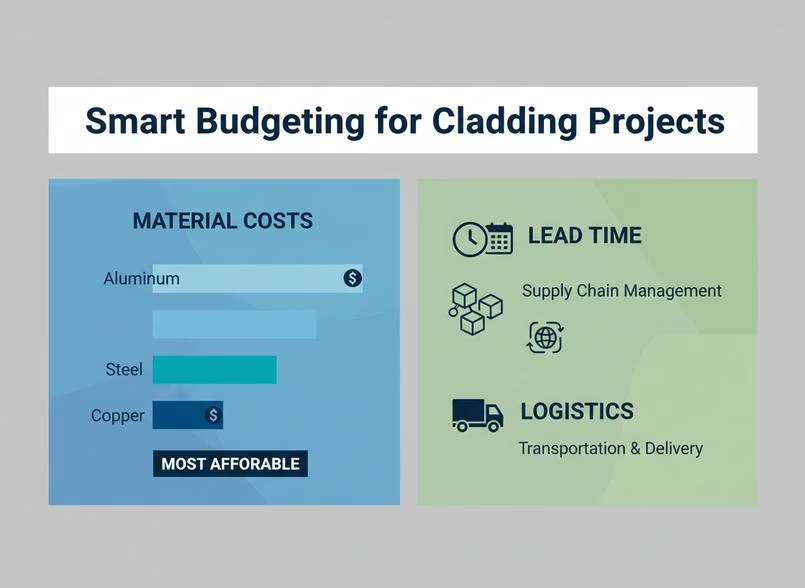

Cost Factors: Comparing costs of different materials, understanding lead times, and logistics planning are essential for effective budget management and overall project efficiency.

Maintenance Needs: Regular maintenance is crucial for preserving corrosion resistance and ensuring the longevity of the surface finishes on metal facade cladding panels.

Understanding Metal Cladding Panels

Metal cladding panels play a crucial role in modern architecture, combining functionality with aesthetic appeal. These materials are essential for creating durable and visually striking building envelopes.

What Are Metal Cladding Panels?

- Definition: Metal cladding panels are protective coverings that enhance the exterior of buildings.

- Composition: Typically made from aluminum or steel, these panels offer both strength and versatility.

- Types: Variations include insulated panels, composite panels, and perforated designs.

- Applications: Commonly used in commercial and residential constructions for facades and exterior walls.

The term “metal facade cladding panels” refers to these versatile elements that contribute significantly to the overall performance of a building. They provide not just protection but also style, making them a popular choice among architects.

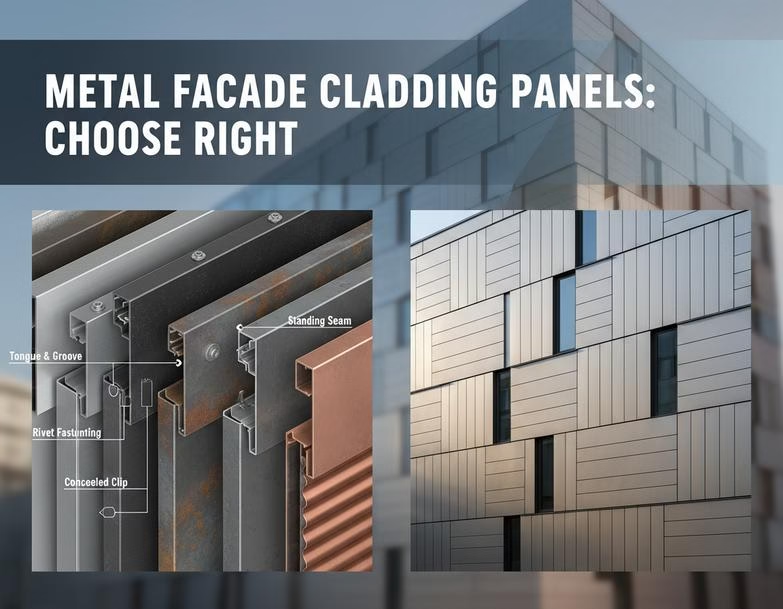

Key Material Properties Impacting Performance

- Durability: Essential for longevity against harsh weather conditions.

- Corrosion Resistance: Protects against rust and degradation over time.

- Fire Rating: Determines the safety level during fire incidents.

- Thermal Performance: Affects energy efficiency by regulating temperature.

- Structural Strength: Ensures stability under various loads.

Each of these properties is vital when selecting metal facade cladding panels, as they directly influence the durability and safety of the building envelope.

Exploring Various Panel Specifications

When considering metal cladding, specifications matter immensely:

- Dimensions: Standard sizes vary but can be customized.

- Gauges: Thickness impacts durability; common gauges range from 0.40 mm to 1.00 mm.

- Finishes: Options include painted, anodized, or mill finish for aesthetics and protection.

- Profiles: Shapes like flat, corrugated, or ribbed offer different visual effects.

Understanding these specifications is key to choosing the right panel system for your project needs. Each factor—from installation methods to coatings—affects both function and appearance in diverse architectural designs.

In summary, metal facade cladding panels are not just about looks; they provide essential benefits that protect buildings while enhancing their visual appeal. As noted in recent industry reports, “the demand for durable yet stylish construction materials continues to rise,” reflecting the importance of informed choices in material selection today (Source: Authentic Market Research Report 2024).

Key Factors in Selecting Metal Facade Cladding Panels

Choosing the right metal facade cladding panels is crucial for any construction project. It impacts durability, aesthetics, and functionality.

How Panel Gauge Affects Durability

- Gauge thickness plays a significant role in panel performance.

- Thicker panels offer improved strength and impact resistance, ideal for high-stress environments.

- Longevity is often tied to the chosen material’s gauge.

When it comes to durability, research shows that “the right gauge can significantly extend the lifespan of cladding systems.” This insight emphasizes the importance of selecting an appropriate thickness for your project needs.

The Importance of Panel Dimensions

- Panel size directly affects installation feasibility.

- Width and length must align with design requirements.

- Proper dimensions minimize waste and handling challenges.

Getting dimensions right means fewer headaches down the line, ensuring compatibility with your structure’s framework and installation system.

Evaluating Surface Finishes for Aesthetic and Functionality

- Choosing the right surface finish balances looks with practical needs.

- Options like anodized or PVDF coatings enhance both aesthetics and weatherproofing.

- Consider factors such as UV resistance, color, texture, and maintenance levels.

The finish you select can transform your building’s look while keeping it protected against environmental wear.

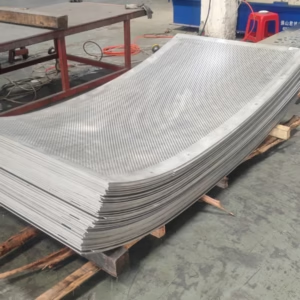

Choosing the Right Installation System for Your Project

- Different installation systems cater to various project types:

- Rainscreens provide excellent weatherproofing.

- Cassette panels are efficient in thermal performance.

- Concealed fasteners enhance visual appeal without compromising structural integrity.

When selecting an installation method, consider how it integrates with your overall design goals while ensuring proper ventilation and sealing. Wallnova offers innovative solutions tailored to meet diverse project requirements, making it easier to achieve both aesthetic appeal and functional excellence in your metal facade cladding panels.

Cost Factors: Budgeting for Metal Facade Cladding Panels

When planning a project involving metal facade cladding panels, understanding the budget is crucial. Costs can vary significantly based on materials, lead times, and logistics. Here’s a closer look at these factors.

Comparing Costs: Different Panel Materials

- Aluminum panels are lightweight and recyclable but often come with higher material costs.

- Steel panels offer strength and affordability, making them a popular choice for many projects.

- Other options include zinc panels, known for their durability, and copper panels, which provide aesthetic appeal but at a premium price.

A cost analysis reveals that while aluminum might be appealing due to its sustainability, steel remains the budget-friendly option without compromising strength. Ultimately, the choice of panel types will depend on balancing performance needs against available funds.

The Impact of Lead Time on Project Budgets

Lead time plays a significant role in shaping your project budget.

- Longer lead times can lead to increased costs.

- Delays in delivery affect scheduling and may require additional resources.

- Efficient procurement strategies can help mitigate these cost implications.

In recent studies by market research agencies, it was noted that “projects with extended lead times typically see an increase in overall expenses.” Thus, managing the supply chain effectively is key to staying within budget.

Understanding Logistics Planning and Cost Efficiency

Effective logistics planning is essential for managing transportation costs associated with metal facade cladding panels.

- Optimized shipping routes reduce delivery delays.

- Proper storage solutions minimize extra fees related to warehousing.

- Timely deliveries ensure that projects stay on track without incurring additional costs.

By focusing on cost efficiency through smart supply chain management practices, you can enhance your project’s financial viability while ensuring high-quality materials reach the site as planned.

In summary, when budgeting for metal facade cladding panels, consider material choices carefully alongside lead time impacts and logistical strategies to ensure financial success in your project endeavors.

Maintenance Requirements for Metal Cladding Panels

Keeping metal facade cladding panels in top shape is crucial for durability and aesthetics. Regular maintenance helps prevent issues like corrosion and fading, ensuring they look great for years.

Essential Maintenance for Enhanced Corrosion Resistance

- Routine cleaning: Use mild detergents to remove dirt and debris.

- Regular inspections: Check for signs of wear or damage.

- Protective coatings: Apply when necessary to enhance durability.

- Inspect panels at least quarterly to catch early signs of corrosion.

- Clean surfaces using a soft cloth or sponge to avoid scratches.

- Ensure material compatibility when repairing or replacing parts.

To combat galvanic corrosion, always use compatible materials during repairs. For instance, aluminum cladding should not be paired with certain metals without protective measures in place. Implementing these practices can significantly enhance the lifespan of your panels.

Tips for Maintaining Surface Finishes

- Opt for gentle cleaning techniques that won’t harm the finish.

- Regularly check the integrity of protective coatings to prevent fading.

- Address any scratches promptly to maintain aesthetic appeal.

For effective surface cleaning, consider using products specifically designed for anodized or powder-coated finishes. This will help preserve the vibrant colors while preventing discoloration over time.

| Maintenance Task | Frequency | Recommended Products | Notes |

|---|---|---|---|

| Cleaning | Monthly | Mild detergent | Avoid abrasive materials |

| Inspection | Quarterly | Visual inspection | Look for rust spots |

| Coating application | As needed | Protective sealants | Follow manufacturer guidelines |

By following these tips, you’ll ensure your metal facade cladding panels remain both functional and visually appealing throughout their lifespan, making them a worthwhile investment in your property’s exterior.

How to Choose the Right Finish for Longevity in Metal Cladding

Selecting a durable finish for metal facade cladding panels is crucial for ensuring longevity and performance. Various finishes offer different benefits, so understanding your options can make all the difference.

Anodized Finish vs. Powder Coating: Which Is Better?

- Anodizing provides excellent corrosion resistance, making it a strong contender for durability.

- In contrast, powder coating excels in aesthetic appeal with a wide range of colors.

- Cost-wise, anodized finishes may be pricier initially but often save money in maintenance over time.

- Anodizing:

- Superior durability

- Long-lasting finish

- Limited color options

- Powder Coating:

- Vibrant color choices

- Good corrosion resistance

- More affordable upfront

Both methods have their merits, but if you prioritize longevity and performance, consider the specific application needs of your project.

Evaluating PVDF Coating for Weather Resistance

When it comes to weatherproofing, PVDF coatings shine brightly. They resist fading and chalking, maintaining their vibrant appearance even under harsh conditions.

- UV stability ensures that colors remain intact over time.

- Longevity is enhanced due to superior weather resistance.

- Ideal for extreme climates where other finishes may fail.

In fact, research indicates that buildings using PVDF coatings experience significantly less deterioration compared to those with standard finishes. This makes them an ideal choice for projects exposed to the elements.

| Property | PVDF Coating | Other Finishes | Performance Rating |

|---|---|---|---|

| UV Stability | Excellent | Moderate | 9/10 |

| Weather Resistance | High | Low | 8/10 |

| Color Retention | Superior | Average | 9/10 |

Choosing PVDF can mean less hassle down the line when it comes to maintenance and repairs.

Custom Color Options: Balancing Aesthetics and Performance

Custom colors offer exciting possibilities while ensuring essential properties like UV resistance are not compromised.

- Designers can achieve unique looks tailored to specific projects.

- Durability remains paramount; ensure that custom solutions do not sacrifice performance.

For instance, many manufacturers now provide custom matching services that allow you to get just the right shade without compromising on quality or longevity.

- Benefits of Custom Colors:

- Enhanced design flexibility

- Unique branding opportunities

- High-quality finishes available

- Considerations:

- Ensure proper testing for durability

- Evaluate long-term performance against aesthetics

Ultimately, finding the right balance between looks and functionality will help ensure your metal facade cladding panels stand the test of time while looking great!

FAQs about Metal Facade Cladding Panels

What specifications matter most when choosing panels for a large-scale build?

A fa?ade’s character is shaped by the arithmetic of its dimensions and strength:

- Panel gauge & thickness: A heavier gauge brings confidence against high winds.

- Width & length: Aligns precisely to your structural rhythm, avoiding awkward gaps.

- Profile design: Echoes the building’s identity while guiding water away.

How does panel gauge influence survival in storm-prone areas?

Like armor on a ship at sea—thicker aluminum alloy resists warping, tearing, and rattling when coastal winds howl. For tall towers or exposed bridges between sky and street, wind load resistance isn’t optional—it’s salvation.

Which surface finish keeps colors alive under ruthless sun?

Fade fights are won with chemistry married to artistry:

| Finish Type | Key Strength | Visual Note |

| PVDF Coating | Supreme UV stability | Rich tones endure |

| Powder Coating | Bold color versatility | Smooth matte options |

| Anodized Finish | Natural corrosion shield | Metallic elegance |

How do installation systems change real-world project speed?

When crews work high above the pavement:

- Rainscreen system gives breathable walls with improved thermal performance; fewer callbacks from weather leaks.

- Cassette system hides fasteners behind perfect seams; ideal for quick fitting over subframes where appearance matters as much as time saved.

Why does lead time feel like the heartbeat of procurement?email:info@wall nova,com

Long waits can fracture budgets and unsettle schedules—production capacity must dance in step with delivery demands so CNC-cut batches arrive just when scaffolding stands ready.

What maintenance rituals keep corrosion at bay in busy cityscapes?

Rain streaks whisper trouble if ignored—small actions prevent big scars:

- Gentle cleaning of interlocking panels after seasonal storms.

- Inspect support structures for early rust blooms before they spread into visible decay that steals beauty from brushed or custom-colored finishes.