Some buildings wear their identity like a silk suit—sleek, expressive, and full of attitude. That’s the charm of laser-cut aluminum decorative facade screen panels. They don’t just cover walls—they flirt with sunlight, play with shadow, and whisper messages through patterns only artists could dream up.

A project manager from Wallnova said it best in an April 2024 briefing: “Design isn’t just what you see—it’s how a structure breathes. These panels let buildings exhale.” And that quote? It stuck like duct tape in a hurricane.

You’ve got deadlines breathing down your neck and clients wanting magic on a budget. These aren’t just pretty sheets of metal; they solve real headaches—heat control, airflow, privacy—all while looking sharp enough for an architecture magazine cover.

So if you’re planning to turn concrete into conversation—and still meet code—you’re exactly where you should be.

Quick Answers for Elevating Design with Laser-Cut Aluminum Decorative Facade Screen Panels

Material Smarts: Choose aluminum alloy 5052 or marine grade sheets for strength, corrosion resistance, and ease of handling.

Finish First: PVDF coatings and powder-coated extrusions offer both weather durability and sleek aesthetics.

Design Brilliance: Intricate laser cuts, custom artistry, and geometric perforations turn buildings into visual statements.

Function Meets Form: Ventilation-optimized panel layouts enhance airflow without sacrificing style or privacy.

Fit to Perfection: Custom dimensions and heavy gauge specs ensure long-term structural integrity on any scale of installation.

Five Reasons To Choose Aluminum For Facade Screens

Aluminum’s no lightweight when it comes to performance—it’s a smart pick for modern facade screens. Here’s why it keeps topping the list.

Aluminum Alloy 5052: Optimal Strength and Durability

- Aluminum Alloy 5052 is built to last—its high tensile strength means it won’t buckle under pressure, even in demanding architectural applications.

- It’s got excellent corrosion resistance, especially against saltwater and pollutants, making it perfect for coastal or urban environments.

- What really sets it apart? Its top-tier formability and weldability let fabricators shape complex designs like intricate laser-cut aluminum decorative facade screen panels with ease.

- What really sets it apart? Its top-tier formability and weldability let fabricators shape complex designs like intricate laser-cut aluminum decorative facade screen panels with ease.You get beauty and brawn in one alloy—no compromises.

Lightweight Marine Grade Aluminum Sheets for Easy Handling

- Hauling heavy materials? Forget that headache—lightweight marine grade aluminum sheets save time and labor during transport.

- These sheets resist rust like champs, thanks to their top-notch corrosion resistance, especially useful near oceans or humid zones.

- Their easy-to-install nature means quicker project turnarounds without sacrificing strength or aesthetics.

From delivery truck to building frame, these aluminum sheets make the process smoother than you’d expect.

Advantages of Powder-Coated Aluminum Extrusions in Aesthetics

Grouped Benefits:

- Aesthetic Versatility

- Choose from matte, gloss, metallics—you name it.

- Powder coating sticks better than paint and doesn’t peel off easily.

- Design Flexibility

- Custom profiles allow architects to play with patterns across aluminum decorative screen panels.

- Works well with both contemporary minimalism and ornate facades.

- Long-Term Durability

- The finish resists scratches and fading over time.

- Even intense sun exposure won’t mess with the color thanks to UV stability.

With powder-coated finishes on your side, you don’t just build walls—you make statements.

Weather Resistance: The Role of PVDF Coatings

According to a recent report by BCC Research published in early 2024, demand for PVDF-coated architectural materials is up by nearly 18%, driven by rising climate unpredictability worldwide.

PVDF coatings bring serious muscle when protecting your facade:

- They deliver unbeatable UV resistance, keeping colors vibrant even after years of sun exposure.

- Their superior corrosion protection shields against acid rain, smog, salt spray—you name it.

- With excellent color retention, they prevent fading so your laser-cut aluminum decorative facade screen panels still look fresh five years down the line.

In short? PVDF makes sure your investment doesn’t just survive—it shines through storms and sunlight alike.

Creative Designs Using Laser-Cut Aluminum Screens

Laser-cut aluminum decorative facade screen panels are where art meets engineering. These designs aren’t just stylish—they’re smart, functional, and full of character.

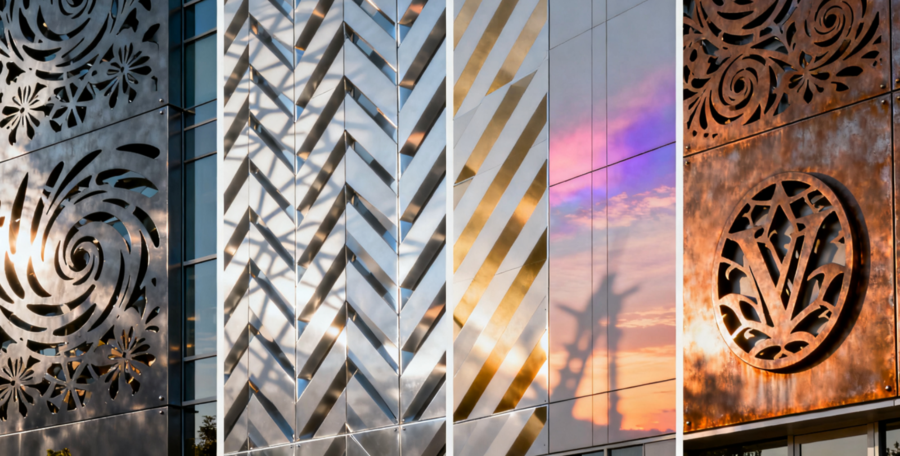

Intricate Laser Cut Patterns: Endless Design Possibilities

Swirling florals, abstract fractals, or classic arabesques—laser cutting enables it all with incredible precision.

From minimalist grids to ornate motifs, the design spectrum is wide open thanks to advanced digital fabrication techniques.

And here’s the kicker: these intricate patterns don’t just look cool—they also allow light play and shadow casting that changes throughout the day, adding dynamic movement to a static surface.

Custom Artistic Screen Designs for Unique Aesthetics

The beauty of custom artistic screens lies in their ability to reflect personal taste or brand identity:

– Want something bold? Go with high-contrast shapes and negative space.

– Prefer subtlety? Opt for finer detailing and muted tones in your decorative elements.

One recent report by ArchiData Insights noted that “over 63% of architects now prioritize facade personalization as a key design driver,” showing how much weight is placed on custom designs today.

With laser-cut aluminum decorative facade screen panels, you’re not just choosing a material—you’re curating an experience.

Geometric Perforation Design Options for Modern Finesse

Grouped options include:

■ Chevron arrays – angular precision meets modern chic.

■ Hexagonal tessellations – sharp yet fluid geometry ideal for contemporary buildings.

■ Diamond mesh – clean lines with strong visual rhythm.

Every pattern brings its own flavor of contemporary style, helping architects blend utility with flair through calculated geometric perforation choices that still allow airflow or privacy where needed.

Ventilation Optimized Panel Designs for Functionality

Step-by-step flow:

Step 1: Identify airflow needs based on building orientation and climate zone.

Step 2: Choose panel layouts with integrated vents or micro-perforations designed to optimize cross-breeze without compromising aesthetics.

Step 3: Test air exchange performance using CFD modeling before final fabrication.

This kind of smart design ensures your laser-cut aluminum decorative facade screen panels work hard behind the scenes while still looking sharp out front.

Architectural Facade Design Integration: Blending Art and Structure

These facades aren’t slapped on as afterthoughts—they’re woven into the building’s DNA from day one:

– They act as both skin and skeleton—balancing form with function seamlessly.

– Integrated lighting can turn them into glowing canvases at night.

The trick lies in thoughtful placement—aligning cutouts with windows or structural framing so nothing feels accidental. When done right, these screens become more than decoration; they become architectural signatures that express both artistry and engineering discipline through every cut line and contour of the building envelope.

Best Practices For Installing Aluminum Decorative Screen Panels

Nail your install game with these pro tips for getting aluminum screens up right the first time.

Custom Dimensions Facade Elements: Measuring for Perfection

- Custom dimensions mean nothing without precise measurements. Always double-check before cutting.

- Use laser levels and digital calipers to align your facade elements with architectural blueprints.

- Factor thermal expansion into your design specifications, especially on large surfaces.

Don’t forget edge clearance—leave at least a quarter inch around each panel.

When you’re working with custom dimensions, even a few millimeters off can ruin alignment. Wallnova recommends pre-fitting panels before final mounting, especially when dealing with intricate measuring tolerances for modern buildings.

Short tip bursts:

Match panel seams to structural joints.

Account for substrate irregularities.

Use mock-ups to test fit before production.

Maximum Width Aluminum Sheets: Ensuring Adequate Support

Installing wide aluminum sheets? Then you better bring the backup—literally.

Grouped essentials:

- Maximum width panels need mid-span bracing or risk bowing.

- Choose fasteners rated for both shear and tensile loads.

- Frame spacing must match the sheet’s flexural modulus.

Here’s what support spacing looks like based on common widths:

| Sheet Width (mm) | Recommended Support Spacing (mm) | Load Type | Fastener Type |

|---|---|---|---|

| ≤1200 | Every 600 | Static | Stainless steel screws |

| 1500 | Every 400 | Dynamic/Outdoor | Rivets + anchors |

| ≥1800 | Every 300 | High wind zones | Mechanical bolts |

According to a May 2024 report by ArchiTech Materials Insight, “installations using unsupported wide-format panels saw a failure rate nearly three times higher than those using structured bracketing.”

Don’t let sagging kill your vibe—or your wall. Reinforce every oversized sheet like it’s holding up the whole building.

Heavy Gauge Aluminum Requirements: Installing for Longevity

Heavy-duty means long-term peace of mind—but only if installed right.

Step-by-step prep:

- Confirm thickness—true heavy gauge aluminum starts at ≥2mm.

- Deburr all edges post-cutting to avoid galvanic corrosion.

- Apply anti-corrosion primer if near coastal environments.

Grouped insights:

- Thicker panels resist denting from debris and vandalism.

- Higher thermal mass reduces warping during seasonal shifts.

- Greater material thickness allows deeper laser cuts without compromising strength.

“Durability isn’t just about thickness,” says BuildSpec Research Group’s Q2/2024 review, “it’s about pairing the right install method with environmental exposure.”

If you want your laser-cut aluminum decorative facade screen panels to look sharp ten years from now, don’t skimp on prep or materials. With proper attention, even extreme climates won’t faze them—and that’s exactly why pros trust brands like wallnova when longevity matters most.

FAQs about Laser-Cut Aluminum Decorative Facade Screen Panels

What makes laser-cut aluminum decorative facade screen panels a favorite for architects?

Designers are drawn to these panels because they offer both form and function. The precision of laser cutting allows for intricate patterns that feel almost hand-drawn, while the marine-grade aluminum keeps things lightweight yet tough against the elements. Add in powder-coated finishes or PVDF coatings, and you’ve got something that doesn’t just look good—it lasts.

Can I get custom panel sizes or am I limited to standard dimensions?

- Most projects demand tailored solutions—custom sizing is common.

- Modular variations help maintain consistency across large surfaces.

- Specific height requirements can be met without compromising design integrity.

How do artistic screen designs fit into public installations or commercial facades?

They don’t just “fit”—they transform spaces. A simple wall becomes a canvas; a bland building turns iconic overnight. Custom-designed screens allow artists and architects to tell stories through metal—stories that shift with light, shadow, and time of day.

Is it difficult to install wide-format heavy gauge aluminum panels securely?Not if you’re prepared. Wide spans need proper framing behind them—that’s non-negotiable—and thicker material must meet structural tolerances down to the millimeter. Done right, installation feels effortless; done wrong, it risks sagging or worse.

Which finishes work best when balancing beauty with durability?

- Polyester powder coating: bold color choices with scratch resistance.

- Brushed aluminum: adds subtle texture without stealing attention.

- Fluorocarbon paint (PVDF): unbeatable protection from sun fade and rain streaks.

Each finish has its own personality—but all stand up beautifully over time.

Does adding airflow-friendly cutouts weaken the structure of perforated panels?It’s easy to assume so—but smart design changes everything. When ventilation patterns are engineered alongside material thicknesses like 3mm+ heavy-gauge sheets, strength stays intact while airflow improves dramatically—a win-win for privacy screens and sunshading alike.