Facade/Aluminium Panel/Mesh Panel

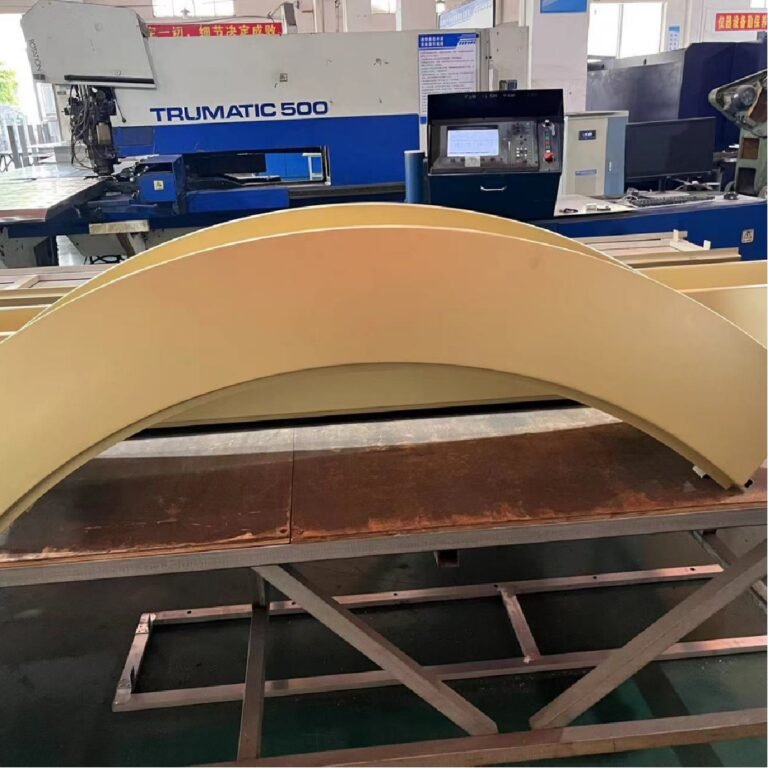

WALLNOVA PROJECT:ICONSIAM Product: Aluminum panel for facade & Mesh screen Area: Over 30,000SQM Location : Bangkok Thailand Wallnova curtain wall building material product attributes Aluminum pannles supplier WallNova Architectural Products Co., Ltd Place of Origin Guangdong,China Brand Name WALLNOVA Type Curtain Walls, Building Material Wall Decorative Product name Aluminum Veneer / Aluminum Plate / Aluminum panel Application Building, Mall, Outdoor curtain wall decoration Aluminum Color Customized Usage Building Exterior Wall Decoration Style Building Decoration Facade Panel Design Customized Aluminum Wall Cladding Keywords Aluminum Wall Panel,Aluminum ceiling,Aluminum cladding Feature Environment Friendly About Wallnova WALLNOVA is one of most famous brand and leading group specialized in design Aluminum producing, installation and maintenance of Metal Ceiling and Cladding in China. With more than 15 years’ experience and contribution in this industry, WALLNOVA is recognized as one of the leading suppliers of advanced metal cladding and ceiling products and technologles in China. Main Product Types 1. Aluminum Composite Panels: Known for their lightweight and sturdy characteristics, suitable for architectural facades and signage production. 2. Curtain Wall Panels: Available in a range of colors and surface treatments, ideal for commercial building exterior designs. […]

Bulk customization is available for project orders. Specifications and delivery are confirmed after design review.

WALLNOVA PROJECT:ICONSIAM

Product: Aluminum panel for facade & Mesh screen

Area: Over 30,000SQM

Location : Bangkok Thailand

Wallnova curtain wall building material product attributes

| Aluminum pannles supplier | WallNova Architectural Products Co., Ltd |

| Place of Origin | Guangdong,China |

| Brand Name | WALLNOVA |

| Type | Curtain Walls, Building Material Wall Decorative |

| Product name | Aluminum Veneer / Aluminum Plate / Aluminum panel |

| Application | Building, Mall, Outdoor curtain wall decoration |

| Aluminum Color | Customized |

| Usage | Building Exterior Wall Decoration |

| Style | Building Decoration Facade Panel |

| Design | Customized Aluminum Wall Cladding |

| Keywords | Aluminum Wall Panel,Aluminum ceiling,Aluminum cladding |

| Feature | Environment Friendly |

| About Wallnova |

WALLNOVA is one of most famous brand and leading group specialized in design Aluminum producing, installation and maintenance of Metal Ceiling and Cladding in China. With more than 15 years’ experience and contribution in this industry, WALLNOVA is recognized as one of the leading suppliers of advanced metal cladding and ceiling products and technologles in China.

|

| Main Product Types |

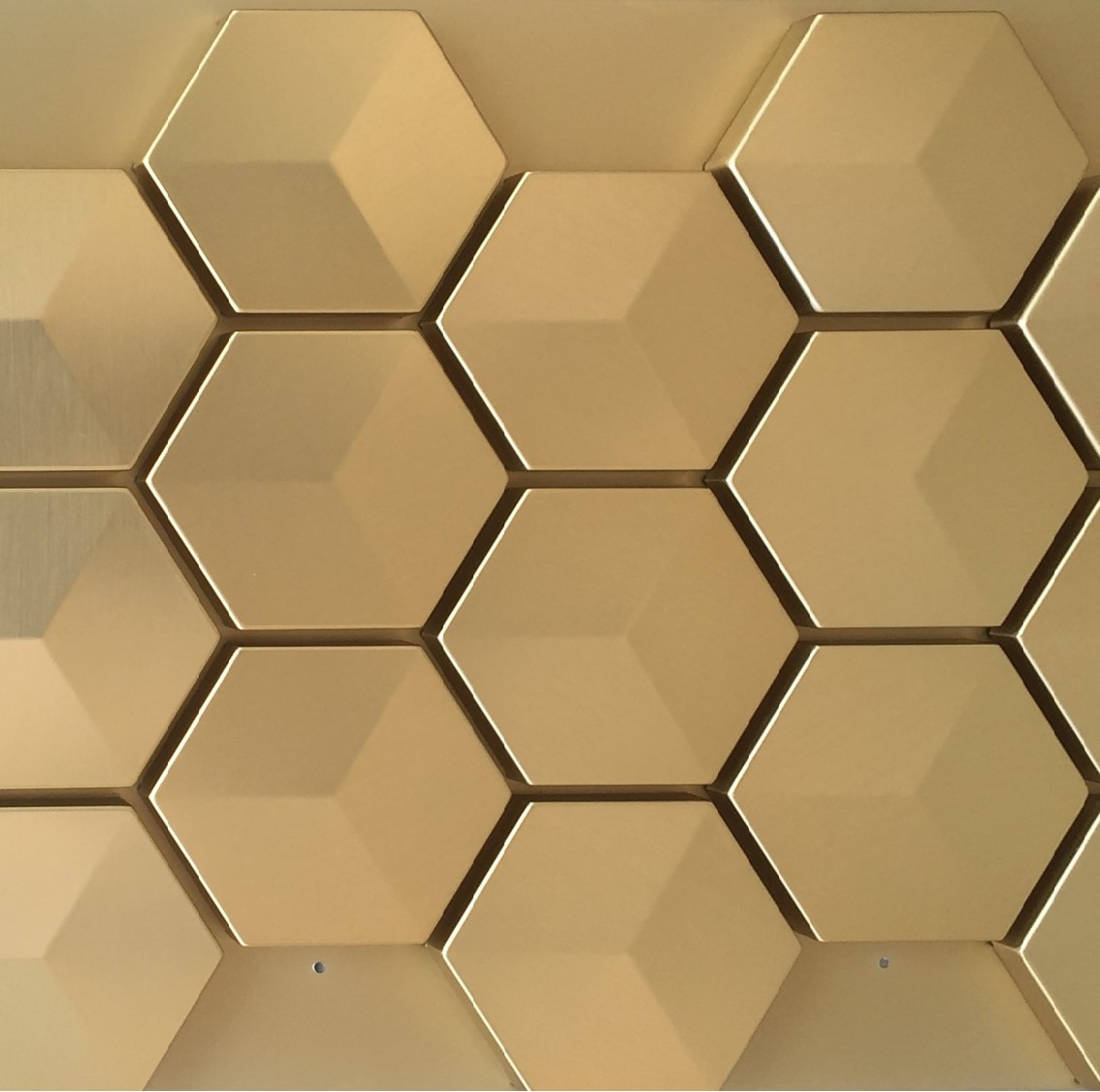

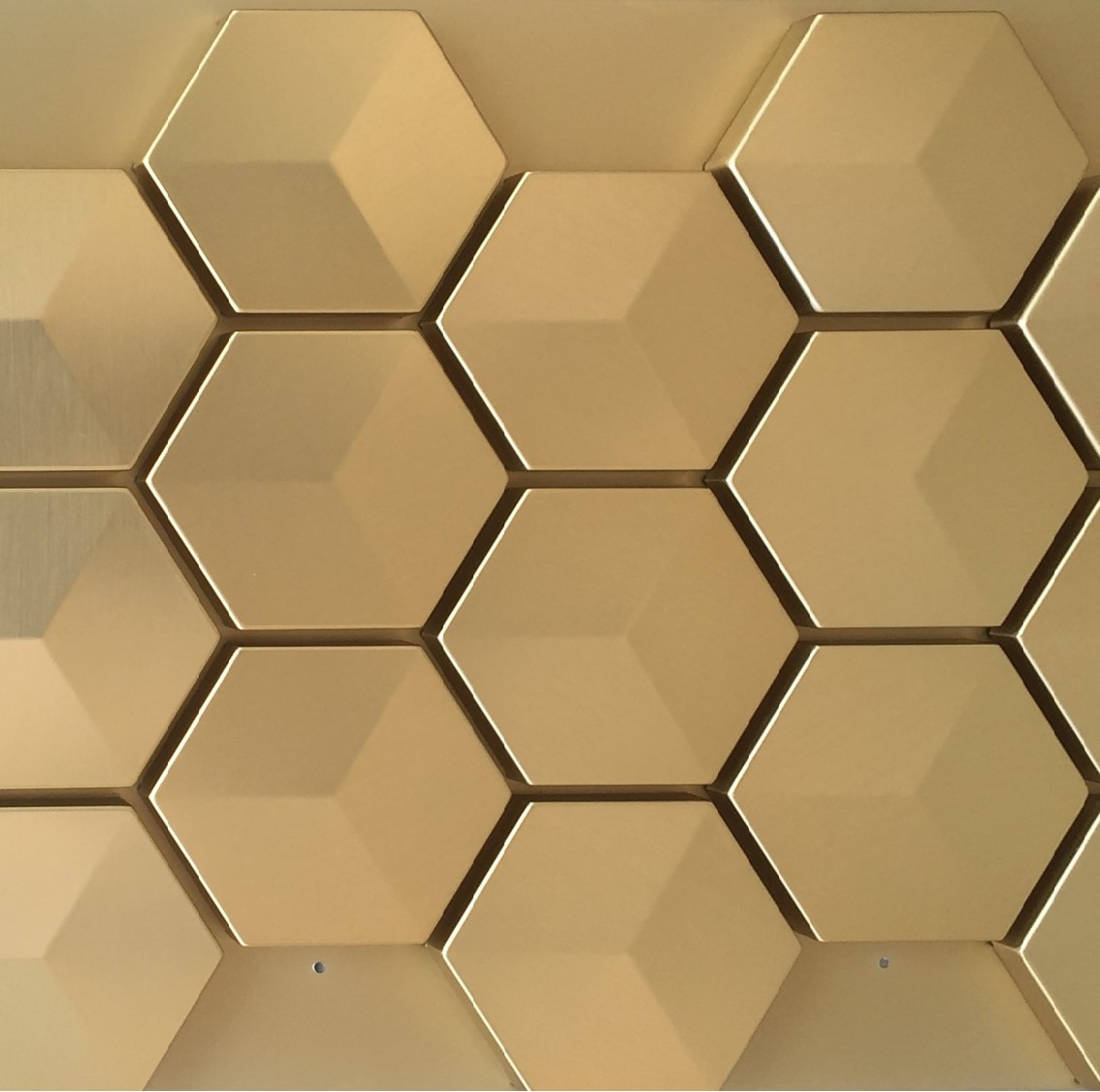

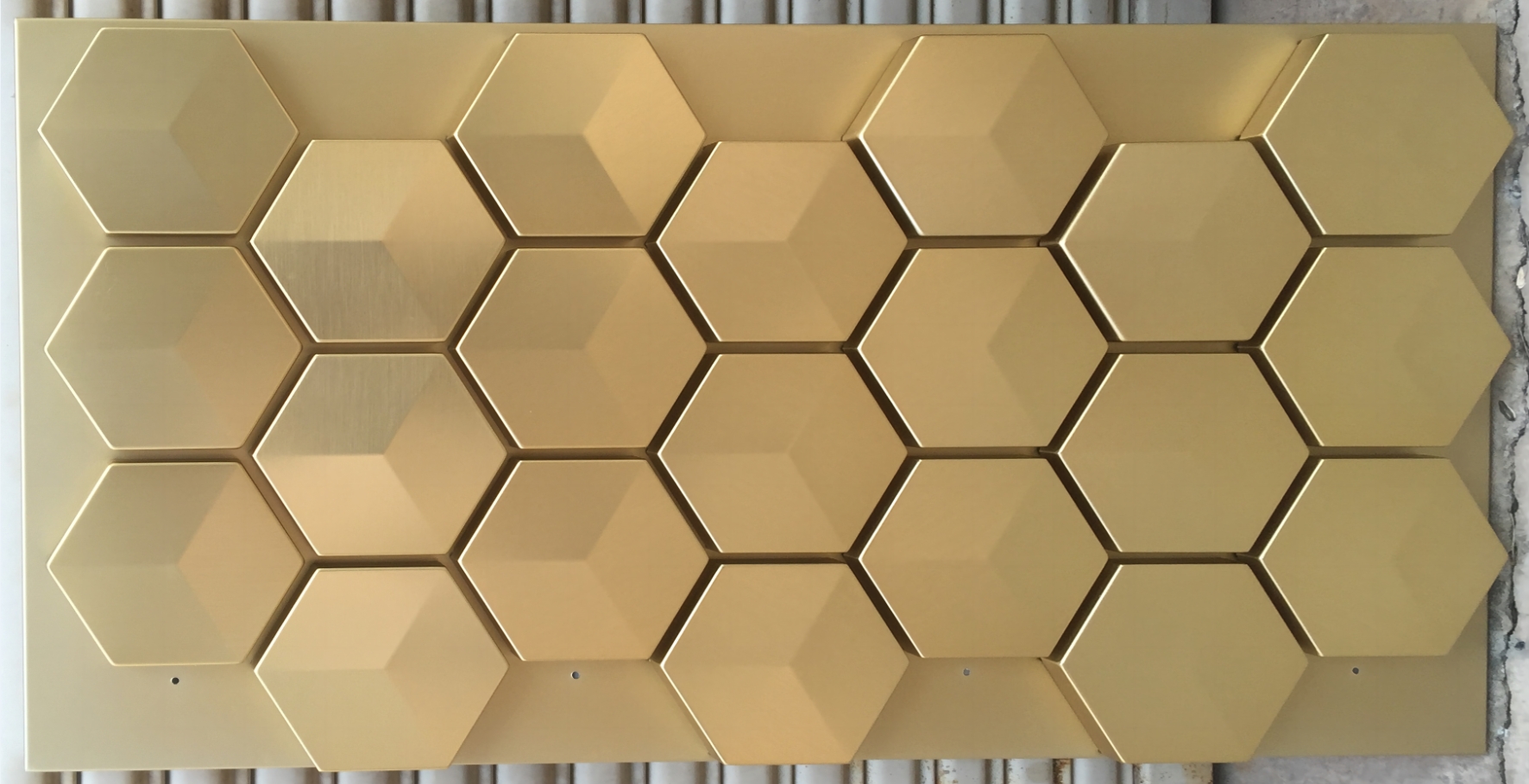

1. Aluminum Composite Panels: Known for their lightweight and sturdy characteristics, suitable for architectural facades and signage production. 2. Curtain Wall Panels: Available in a range of colors and surface treatments, ideal for commercial building exterior designs. 3. Honeycomb Panels: Favored for their lightweight structure and high strength, applicable in aerospace and high end architectural projects. 4. Perforated Panels: Enhance architectural aesthetics and serve decorative purposes in interior design.

|

| Key Product Features: |

1. High Quality Aluminum Sheets: Produced using premium aluminum alloy raw materials, exhibiting excellent durability and strength. 2. Customization Options: Offers various sizes, thicknesses, and surface treatment options to cater to diverse customer requirements. 4. Wide Applications: Suitable for aerospace, automotive manufacturing, architectural decoration, electronic devices, and more. 5. Environmentally Sustainable: Committed to using sustainable materials and production processes in alignment with environmental standards.

|

| Contacts WALLNOVA |

If you have any questions, please contact me by Email: info@wallnova.com For more project case details, please visit wallnova website: http://www.wallnova.com.

|

| Installation Precautions |

1.Design Review: Before installation, carefully review the design drawings and documents to ensure all dimensions and specifications meet architectural requirements. 2.Material Inspection: Check the quality and integrity of all aluminum panels and components to ensure there are no defects or damages. 3.Structural Assessment: Ensure the main structure of the building can support the weight of the curtain wall and withstand wind pressure, seismic forces, and other natural loads. 4.Waterproofing: Ensure proper waterproof treatment at the joints of the curtain wall to prevent water penetration into the building. 5.Vertical and Horizontal Alignment: Use levels and plumb lines to ensure the vertical and horizontal alignment of the aluminum panels during installation. 6.Expansion Joints: Allow for appropriate expansion joints between the aluminum panels and between the panels and the main structure to accommodate temperature changes. 7.Ventilation: Ensure the curtain wall design provides adequate ventilation to prevent condensation and heat buildup. 8.Installation Sequence: Typically, start from the bottom and install panel by panel upwards, ensuring the stability and safety of the construction. 9.Safety Measures: Construction personnel must wear safety helmets, harnesses, and other personal protective equipment, and ensure all safety equipment used meets safety standards. 10、Professional Installation: It is recommended to have professional installation teams to ensure quality and safety.

|

| Maintenance Precautions |

1.Regular Inspections: Regularly inspect the integrity of the curtain wall and fasteners to ensure there is no loosening or damage. 2.Cleaning: Clean the aluminum panels regularly based on environmental conditions and usage to maintain their appearance and performance. 3.Waterproof Maintenance: Check the condition of sealants and waterproof membranes, and replace damaged parts in a timely manner. 4.Corrosion-Prevention:Although aluminum panels are corrosion resistant, check for signs of corrosion, especially in coastal or heavily industrial polluted areas 5.Surface Treatment: If the surface coating or anodized layer is damaged, repair it promptly to prevent further damage. 6.Check Expansion Joints: Ensure expansion joints are not blocked to allow for normal expansion and contraction of the aluminum panels due to temperature changes. 7.Avoid Corrosive Cleaners: Use mild cleaners and water to clean, avoiding corrosive cleaners that may damage the aluminum panel surface. 8.Maintenance Records: Keep records of all maintenance and repair activities to track the condition and maintenance history of the curtain wall. 9.Professional Maintenance: For complex maintenance tasks, such as replacing damaged aluminum panels or carrying out structural repairs, have professional maintenance teams execute the work. 10.Follow Manufacturer’s Guidelines: Adhere to the maintenance and cleaning guidelines provided by the aluminum panel manufacturers to maintain the long-term performance of the curtain wall.

|

Design Features

- Enhanced Thermal Break: 42mm PA66 GF25 thermal break for superior insulation performance

- Triple Glazing Option: 4mm + 16A + 4mm + 16A + 4mm LOW-E configuration

- Pressure Equalized Design: Dual cavity drainage for weather protection

- Structural Reinforcement: 6061-T6 aluminum alloy for high wind load performance

- Custom Finishes: PVDF coating with long-term color retention

Installation Advantages

Factory Quality Control

Units pre-assembled and tested for air, water, and wind performance.

Rapid Installation

Faster installation reduces on-site labor and downtime.

Minimal Disruption

Reduced construction time with clean on-site assembly.

Precision Engineering

Tight tolerance manufacturing ensures consistent alignment.

Project Highlights

- Energy efficiency targets for high-rise towers

- Large panel sizes for reduced joint visibility

- Custom finishes to match facade design intent

Service Scope

- Engineering consultation

- Fabrication and QA

- Export logistics

- On-site installation support

Bulk Inquiry Form

Provide project details and requirements for Facade/Aluminium Panel/Mesh Panel. Our engineering team will respond with recommendations.