Introduction

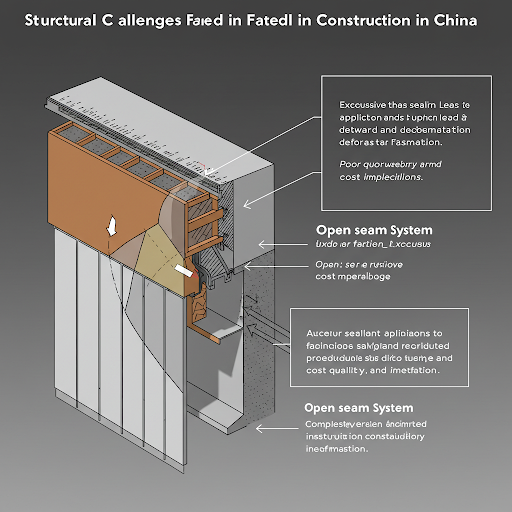

At present, the design and construction of the curtain wall in the industry has formed a misunderstanding, whether it is aluminium or stone curtain wall, where the gap between the exposed surface of the curtain wall unit panels, are coated with weather-resistant silicone sealant, and the tighter the better. If you do not apply glue, he said you cut corners, this concept in the development of China’s curtain wall to this day, in some owners and even many curtain wall technical workers have formed in the mind. Resulting in poor quality of standard specifications, low level of products, manufacturers of shoddy work, the installation of aluminium curtain wall outward deformation. Although there are architects and consultants require the curtain wall using open seam system, but due to construction manufacturers construction technology, construction costs and other reasons, it is often difficult to implement or implement the effect is not ideal, of course, there are also owners found to open the seam, such as the northern weather pollution is more serious, there is a lot of ash between the seams, there are also seams between the waterproofing measures are not very reasonable in the design and construction, resulting in a serious seepage of the dew, and the later still have to be rectified. So the open seam system has not been a real wide range of applications.

Types of Curtain Wall Systems

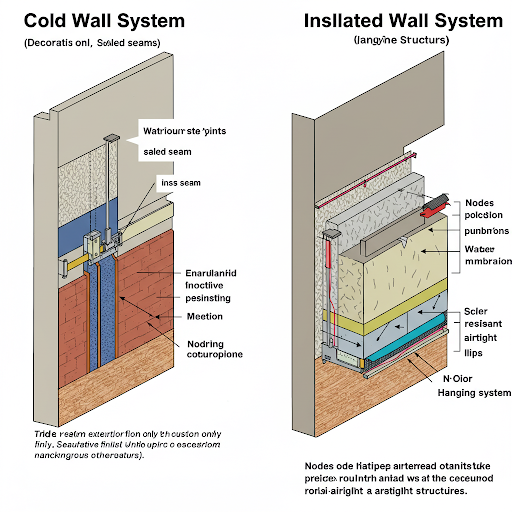

In developed countries such as Germany, the structural design of curtain wall products is very rigorous, they after years of technical discussions and practical summary of the curtain wall products are divided into two categories, one is to protect the warm wall system, the other is a decorative cold wall system. It is introduced as follows:

Keep Warm Wall System

Definition:

As the name implies, the main function of this wall is thermal insulation, that is, the heat exchange between indoor and outdoor walls have a certain blocking effect, such as inside and outside the two sides of the aluminium plate or other metal plates, the middle of the polyurethane, polystyrene or rock wool and other insulation materials composite thermal insulation wall; and then, such as the building envelope using a hidden frame glass curtain wall, all-glass curtain wall, point barge glass curtain wall. These walls are like poured concrete and brick masonry walls, the partition between indoor and outdoor shielding only a shielding band, do not allow indoor and outdoor air convection in this shielding band, so from the process must be sealed on the curtain wall may result in air infiltration of all the gaps and to ensure that the use of the life of a permanent seal!

Decorative Cold Wall System

Definition:

This cold wall of the building two roles, one is to accentuate the architectural effect, the second is to prevent the rain on the building surface of the scouring corrosion, improve the durability of the building. Most of the materials from the material with aluminium, stone, glass and other materials, the use of most of the parts of the building is not light structure of the external surface; from the construction requirements and the building structure to maintain a certain interval, rain leakage using the principle of isobaric design, between the plate to leave the air exchange channel, to maintain the curtain wall and the building structure of the interval within the drying of the dew is easily discharged. Comparison of modern open hot channel curtain wall, actually from the principle is in the original warm wall curtain wall outside and add a decorative cold wall system.

Issues with Improper Application:

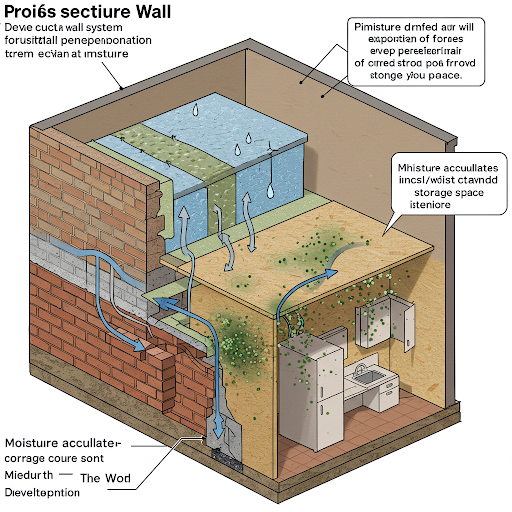

If the decorative cold wall system according to the warm wall construction, that is, Figure 2 decorative cold wall of all the channels all sealed with sealant, will bring the following hidden dangers to the living room:

- Corrosion Due to Condensation:Whether the outer layer of aluminium or stone, there is a barrier layer is bound to produce condensation due to temperature differences, curtain wall connections will produce corrosion, especially two different metal connections due to the potential difference between the two different metals, will be in the medium of dew enhancement of galvanic corrosion, resulting in structural relaxation of the curtain wall and reduce the service life.

2.Chimney Effect:Especially the outer layer of aluminium or slate back coated with anticorrosive paint, the board itself is impermeable, the board all the gaps and then blocked, if the board and the wall interval is greater than 40mm, will produce the chimney effect, so that the intervals between parts of the foundation of the moisture transpiration to speed up the moisture concentration of the interval to increase, then if the insulation layer of the moisture layer is not closed tightly, it will result in the loss of thermal insulation materials saturated with moisture and thermal insulation effect.

3.Indoor Moisture Issues:Some projects due to economic factors, both to have a good external surface of the money spent and can not be more, in the civil engineering structure of the outer side of the thermal insulation layer and waterproof layer, curtain wall and the structure of the wall interval in the moisture due to the aluminium or coated with anticorrosive agents in the stone surface layer is very dense (between the seams of the glue treatment), can not be volatile to the outdoors, can only be penetrated through the concrete body or the brick wall to the indoor. After high-grade renovation of residential walls in the indoor side are generally increased by a layer of plywood, penetration of indoor moisture can not be evaporated, especially the humidity of the kitchen and infrequently open the door of the warehouse, when the festival over the spring sun rises, it will produce difficult to enter the nose of the mouldy, seriously undermining the hygiene of the environment of the living room.

4.Wall Foundation Damage:Dew water deposited in large quantities on the ground floor foundation appearance and penetrate into the wall, will cause the wall thermal resistance to reduce the wall, the wall foundation premature chalking, reduce the service life.

Current Situation in China

Our country is now in the building on the use of aluminium curtain wall most of the architectural effect is mainly to bake, and glass with a reasonable match, showing a clean and upright or solemn and majestic modern architectural modelling art effect, this kind of aluminium curtain wall products from the structure of the design and construction are classified as decorative cold wall system. But in fact, we now have a building of aluminium curtain wall and how? From the product structure design and installation process more than 90% of the warm wall system for the insulation. From a close look at the gaps between the panels coated with weather sealant horizontal uneven, vertical not straight, the surface is not smooth, coupled with the sealant silicone oil precipitation adsorption of dust is more, the surface of the curtain wall is dirty and unpleasant to look at. In the north at least 30% of the aluminium curtain wall panels outward deformation, especially the use of metal fluorocarbon paint spraying panels, panels slightly uneven, there will be a large contrast, from a distance to see the overall aluminium curtain wall surface such as the breeze of the lake water ripples, it is very unsightly, a serious impact on the building’s elegance.

Causes of Aluminium Curtain Wall Deformation

I think that in our current situation, immediately prohibit the protection of warm wall system of aluminium, stone curtain wall applied to the building has a structural wall decorative parts, it is very difficult. The main reason for this is that the national industry standard ‘JGJ133-2001 metal and stone curtain wall engineering technical specifications’ is misleading, the market competition at low prices, the construction period is extremely unreasonable and other factors, in the JGJ133 specification is not clear what is to keep the warmth of the wall, what is the decorative cold wall. Another reason is that the dry sealing of aluminium, stone cold wall system product structure and the current warm curtain wall product structure is different, never the existing aluminium, stone curtain wall of the embedded weatherproof glue removed into a decorative cold wall, which has a technical understanding of the process of improving. I think in the preparation of aluminium, stone curtain wall product standards and the preparation of these two products should be resolved when the standard atlas, but the aluminium curtain wall outward deformation of the image of the new building has too great an impact, and very low curtain wall technology is difficult to meet the international advanced technology, the need for immediate remediation.

Aluminium curtain wall panels why will deformation? The author believes that there are the following main factors:

1.Lack of Side Ribs and Middle Ribs:There are no side ribs and middle ribs in the plate, and the deformation is caused by wind pressure and air rising force.This deformation phenomenon occurs in the use of aluminium-plastic composite panels for the panel of the curtain wall. Building owners in order to save money, the choice of irregular manufacturers. Manufacturers in order to obtain higher profits, what the edge of the rib, the rib is not used. Aluminium composite panels folded into a box, screwed directly to the frame, the panel gap smear glue even if the completion. This curtain wall plate strength is simply not enough, the plate in the positive and negative wind pressure under the role of fatigue fatigue deflection deformation, so that the size of the plate surface growth. Reflect the more prominent sunny side of the curtain wall, due to the construction process is to use the warmth of the wall in the form of the plate gaps all sealed tightly with glue, the plate and the structure of the wall interval in the air in the sun effect of warming, the plate in the air under the action of the upward force caused by outward deformation and deformation.

2.Thermal Stress Due to Fixed Connection:The plate is fixed with the structural frame of the curtain wall, and the thermal stress cannot be released to produce deformation.Aluminium curtain wall in the seasonal temperature difference in the region, in the early spring and autumn at the end of the season of lower temperatures, when the sunlight irradiation thermal effect is very strong, especially the darker colour of the aluminium plate warming, aluminium panels at different temperatures, the thermal expansion of the value of the length of each metre is greater!Curtain wall frame inside, the sun’s influence is weaker, the aluminium plate and the frame can produce a temperature difference of more than 80 ℃ at the maximum, in the aluminium plate size is larger then there will be a large linear expansion difference. If the curtain wall panel structure using folded edges, the aluminium plate will be fixed with screws in the frame of the structure (see Figure 3), will result in the thermal stress of the aluminium plate panel can not be released, forcing the panel to yield, in the role of the air outward deformation phenomenon.This deformation phenomenon is shown to be quite large, especially the aluminium plate inside the curtain wall frame using steel profiles (the word ‘steel profiles’ provided by the industry encyclopedia), because of the thermal expansion coefficient of aluminium is generally two times the steel, so the same size plate deflection will be two times the value of the table.I found that some manufacturers in the fixed plate on the corner code, along the long or wide direction of the plate will be fixed plate screw holes processed into long holes (see Figure 4), but the plate is still installed after the phenomenon of deformation, and this connection does not meet the requirements of in-plane deformation of the curtain wall.

3.Panel and Side Rib Assembly Stress Deformation:Some manufacturers in order to solve the thermal stress deformation of aluminium plate plate, especially when the panel using aluminium-plastic composite panels, in the perimeter of the unit plate with a ring of side ribs frame, from the production process is the panel in the planing machine according to the panel folding size planing groove folding into a box. The other line is the side rib profile is truncated and assembled into a side rib frame according to the required size of the panel. Then the side rib frame is loaded into the box-shaped panel, and the two bodies are fixed with core-pulling rivets. In the work site is often found due to the panel planing groove folding edge deviation, side rib profile assembly into a frame deviation, the two bodies often appear when matching either the box is small or board folding edge size is too large (shown in Figure 5). In order to protect the schedule, no material, often forced assembly, resulting in assembly stress on the board, either the side ribs deformation or board pressure deformation. This plate in the temperature and air expansion force under the deformation phenomenon produced outward.

Remedies for Aluminium Curtain Wall Deformation

Curtain wall product design should be the most basic principles, in addition to ensuring the strength, whether it is the structural framework or finish should be embedded in the body of the structural design, must not be allowed to produce thermal stress. If thermal stress will cause deformation and damage to the component. To achieve the non-thermal stress, the matching parts should leave a certain gap, the designer must have just the right structure or sealing materials to ensure that the product is airtight and watertight. This is the key to the success of curtain wall design.

- Floating Connection of Aluminium Curtain Wall Panels and Frames:Since China’s reform and opening up, all aspects are producing rapid changes, especially the construction industry, but also the vigorous previous development. All over the new building such as spring, and more and more high. To meet the use of ultra-high-rise curtain wall, structurally: one can not produce thermal stress, the second is to meet the ultra-high-rise building (the word ‘ultra-high-rise building’ by the industry encyclopaedia to provide) due to the self-oscillation and in the wind load (the word ‘wind load’ by the industry encyclopaedia to provide) Under the action of amplitude increase, caused by the curtain wall in-plane deformation requirements, and in the seismic design, according to the different types of building structure elasticity calculated displacement control value of three times the design. For example, in the seismically defended area, there is a frame structure super high-rise building with a height of 3.4m between floors, and the displacement of the curtain wall must meet the requirement of 25.5mm. This requires curtain wall panels to meet the strength requirements under the premise of the structural frame must be floating connection, these two diagrams are just a form of panel connection, in product design can design a variety of structures. But no matter what form of structure, the design principle is that the plate connection structure must be able to absorb the material due to the thermal stress generated by the temperature difference and the seismic in-plane deformation requirements.

- Elimination of Assembly Stresses in Aluminium Curtain Wall Panels:Aluminium curtain wall panels if you do not add side ribs, using welding, riveting or directly on the plate stamping molding of the corner code (see Figure 4), is the corner code of the fixing screw holes to open up into long holes, but also can not solve the thermal stress caused by deformation problems. A project with a larger number of boards, board size, some of the differences are large, the board’s maximum thermal expansion due to the board’s length and width of different sizes, not along the board’s length and width of the direction of change, but according to the tangent function of the triangular function of the value of the change, it is not possible to use the project with the perimeter of each board of each corner of the code, are computers according to the corner where the board location of the code may be the direction of the expansion of the direction of the direction of the direction of the open each corner code The diagonal holes for each corner code were made according to this direction. Another factor is that the screws for fixing the plate must be tightened, aluminium plate without edge ribs, the strength of the folded edge is very weak, it is difficult to transfer the thermal stress to the corner code, so that the corner code according to the temperature difference creep to absorb the thermal expansion. Therefore, this method of opening long holes on the corner code can not solve the problem of deformation of aluminium plate.To solve the aluminium plate without deformation, the plate and frame structure must be floating connection. To transfer the thermal stress to the edge of the plate folded edge, it must be added to the plate folded edge of the edge ribs for reinforcement, is the use of 3mm thick single aluminium plate in the seasonal temperature difference in the region should also be set up side ribs for reinforcement. In order to ensure that the folded edge of the aluminium plate does not produce Figure 3, assembly stress, and to ensure the production quality of the aluminium plate block, the side rib frame should be designed for the length and width of the scalable structure. From the tolerance and fit terminology, the plate folded into a box-shaped size for the reference hole, by the expansion and contraction of the side rib frame to match the folded edge of the plate, the side rib frame of the four corners of the part using plug connector (as shown in Figure VIII 3 node). Side rib frame of the horizontal and vertical rods and plugs at each end of the 2mm gap, the box length and width adjustment amount of 4mm, the 4mm enough to absorb the board folded edge and frame assembly processing deviation, can eliminate Figure V with the improper impact on the quality of the phenomenon. This retractable side rib frame not only reinforces the thermal stress conduction, but also absorbs the thermal stress deformation caused by small temperature difference of the side ribs in the panel, thus eliminating the deformation of the aluminium panel and ensuring the overall flatness of the aluminium curtain wall.

- Floating Connection of Aluminium Curtain Wall Panel Reinforcement Ribs:There are about three ways to connect the reinforcing middle rib of aluminium curtain wall panel with the panel (see Figure 9): structural adhesive bonding, super-strong adhesive tape, planting and welding screws, the common feature is that the middle rib is fixed with the panel, and most of the two ends of the middle rib are fixed with the frame of the side ribs.The panel is directly exposed to sunlight, and the reinforcement rib is inside the panel, especially after a layer of bonding adhesive isolation, and the panel due to the temperature difference of thermal stress, which limits the expansion of the panel along the axial direction of the reinforcement rib. If the two ends of the reinforcement ribs are fixed with the frame ribs, it limits the expansion of the panel along the radial direction of the reinforcement ribs, which is easy to cause the shear damage of the adhesive and connectors and reduce the durability.Aluminium curtain wall panel reinforcement rib and plate; connection using Figure 8 1, 2 nodes, the installation sequence is first reinforcement rib ends of the angle code with core rivets or self-service screws and side ribs frame fixed, and then reinforcement rib from the top down into the fixed angle code, and then use high-strength adhesive bonding adhesive along the reinforcement rib length of each third of the sticking a pressure plate, the reinforcement rib pressed. Note that the upper part of the reinforcing centre rib and the pressure plate should leave a 2mm gap, the end of the reinforcing centre rib and the angle code must also leave a 2mm gap between the panel and the centre rib of the floating connection structure will not produce thermal stress, that is, to achieve the role of reinforcing to ensure that the panel is flat.Design of Reinforcing Centre Ribs:

- Shape Requirements: Favourable to the downward rolling down of dew condensation to reach the maximum moment of inertia in y-axis.

- Calculation of Stiffness: Single-span centre rib is calculated as simply supported beam subjected to trapezoidal load under positive wind pressure, and as simply supported beam subjected to three uniformly distributed concentrated forces under negative wind pressure, and its deflection should not be greater than 1/300 of the span of the centre rib.

- Shape Requirements: Conducive to the dew rolled down, have enough rigidity

- Bonding Adhesive: Domestic NJ-1 series of high-strength bonding adhesive

- Performance: Tensile strength 34N/mm2 (metal to metal bonding). Shear strength 36N/mm2 (metal to metal bonding). Curing temperature below 20 ℃ 15-50 minutes, above 20 ℃ 1-20 minutes, 2-3 hours to reach maximum strength.

- Amendments to JGJ133-2001:For the metal plate curtain wall, this technical specification of the following provisions should be revised:

- 5.4.5: Metal panels should be fixed along the perimeter with screws and beams and columns, screws should not be less than 4mm in diameter, the number of screws should be based on the panels subjected to wind load and seismic action determined by calculation.

- 6.4.3: The processing of single-layer aluminium panels shall comply with the following provisions of Article 3

- The fixed corner code of single-layer aluminium plate shall meet the design requirements. Fixed corner code can be welded, riveted or stamped directly on the aluminium plate, and should be accurately positioned and easily adjusted. Fixed firmly.

- The fixed corner code of single-layer aluminium plate shall meet the design requirements, and the fixed corner code can be welded, riveted or stamped;