Architectural swagger meets logistics sanity—Perforated Aluminum Panels redefine façades with style, speed, and large-scale savings.

There’s something oddly poetic about Perforated Aluminum Panels—like the architectural version of Swiss cheese, but with swagger. These sleek metal sheets are punching literal holes into how we think about building façades. What used to be flat and forgettable is now perforated and proud, catching sunlight like a glittering armor while letting buildings breathe easy.

Walk past any new office tower or arts center lately? Odds are, its skin isn’t just there to look pretty—it’s multitasking like your favorite barista during rush hour. Sunshade? Check. Airflow? You bet. Acoustic control? Like a whisper in the wind.

“Design is no longer decoration—it’s performance,” says Lena Hoft, Lead Façade Engineer at Wallnova (2024 Global Materials Insights Summit). “Perforation isn’t just aesthetic—it’s climate strategy.”

And if you’re sourcing for large-scale builds, here’s where it gets spicy: these panels don’t just talk a big game—they deliver on install speed, cost-per-square-foot sanity, and container-friendly logistics that won’t make your procurement team cry into their spreadsheets.

Harmonic Key Points: Perforated Aluminum Panels

→ Material & Finish: Advanced aluminum alloys combined with anodizing, PVDF or powder coatings deliver corrosion resistance and bespoke color/textures.

→ Design & Performance: Tailored hole shapes, patterns, and open-area ratios optimize daylight control, natural ventilation, and acoustic damping.

→ Structural Integrity: Selecting the right thickness, gauge, and material grade balances weight, load capacity, and on-site formability for curved or flat façades.

→ Applications & Functions: From sun-shading cladding and ventilation grilles to acoustic ceilings and balustrade infill, panels merge aesthetics with performance.

→ Manufacturing & Tolerances: Precision punching, shearing, and fabrication maintain tight dimensional tolerances, ensuring seamless alignment and consistent appearance.

→ Cost Control Strategies: Leverage mid-range alloys, full-container orders, efficient packaging, and calibrated ISO certification to optimize budget and logistics.

What Defines Modern Façade Aesthetics Today

Modern façades are more than just outer shells—they’re statements. Let’s break down what’s driving the look and feel of tomorrow’s buildings.

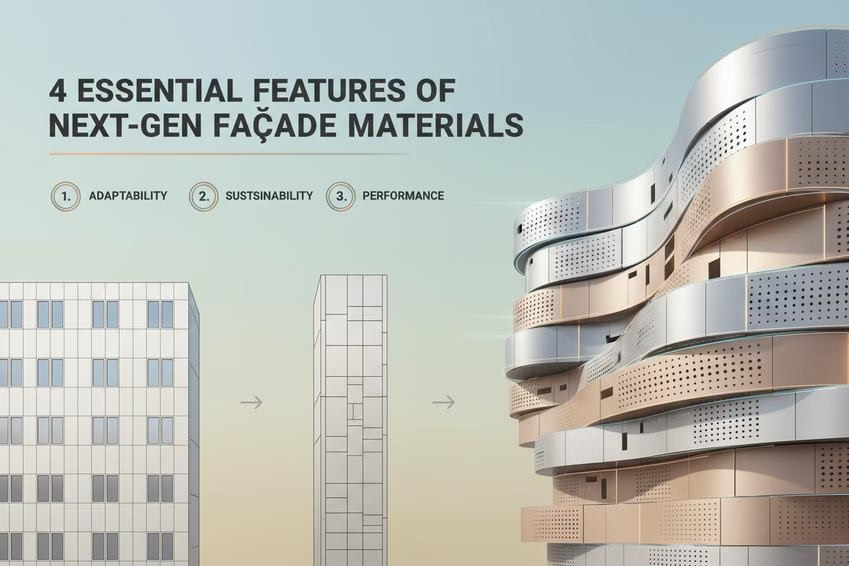

4 Essential Features of Next-Gen Façade Materials

There’s no magic formula, but these traits show up again and again:

- Lightweight performance makes installation easier and reduces load on the structure.

- Corrosion resistance keeps façades looking sharp even in salty coastal air or polluted cities.

- Formability allows for creative curves, folds, and bends—perfect for bold architectural moves.

- Durability, especially with surface treatments like PVDF coatings or anodizing, ensures long-term value.

These features make today’s material innovation not only functional but also expressive—key to modern building envelopes that stand out without falling apart.

How Color Options and Surface Finish Drive Visual Impact

Color isn’t just about looks—it shapes mood and identity.

- Powder coating offers thousands of hues with matte, glossy, or textured finishes.

- Anodized surfaces create metallic tones that shimmer differently depending on sunlight angles.

- Brushed textures add depth while hiding fingerprints—super practical for high-touch zones.

Together, these options transform basic sheets into stylish design elements. Architects now treat color as part of their core design principles, not an afterthought.

| Finish Type | UV Resistance | Texture Variety | Maintenance Level |

|---|---|---|---|

| Powder Coated | High | Extensive | Low |

| Anodized | Very High | Moderate | Very Low |

| Brushed Aluminum | Medium | Limited | Moderate |

This flexibility has made colored cladding systems a top choice in both commercial towers and cultural centers alike.

Why Thickness and Material Grade Influence Structural Elegance

Thickness might sound boring—but it’s one of those hidden heroes behind great design.

Thinner panels offer sleekness but need strong backing systems to stay rigid. Thicker panels? They bring natural stiffness but can weigh more. Balance is everything.

Higher-grade aluminum alloys give better strength-to-weight ratios, letting architects push boundaries without sacrificing safety. These choices affect how well panels adapt to flat walls or complex curves—a big deal when you want your façade to look seamless from every angle.

Short version? The right combo = clean lines + long life + fewer headaches during install.

The Rise of Complex Patterns—From Straight to Staggered Pitch

Designers are ditching plain grids for something way cooler: staggered perforations and irregular rhythms that play with light like never before.

Here’s how it usually unfolds:

Step 1: Pattern Selection

Choose between straight pitch (uniform holes) or staggered pitch (offset rows). The latter gives a more fluid visual texture while boosting airflow through the panel surface—a win-win for both aesthetics and function in modern panel fabrication projects.

Step 2: Customization

Use software tools to simulate how different hole sizes affect shadow casting throughout the day. This helps balance sunlight filtering with privacy needs—especially important in urban settings where glass glare is a real issue.

Step 3: Integration

Combine patterns across panel groups to generate larger-scale visuals like gradients, logos, or even abstract art pieces embedded into the building skin itself—a new frontier in façade storytelling driven by smart use of perforation techniques within advanced perforation patterns design workflows.

Grouped together, these steps redefine what we expect from metal façades—and why architects keep coming back to perforated aluminum panels, again and again.

The Role of Perforated Aluminum Panels in Architectural Expression

Short intro:

Blending form and function, perforated aluminum panels are transforming how buildings breathe, sound, and shine—inside and out.

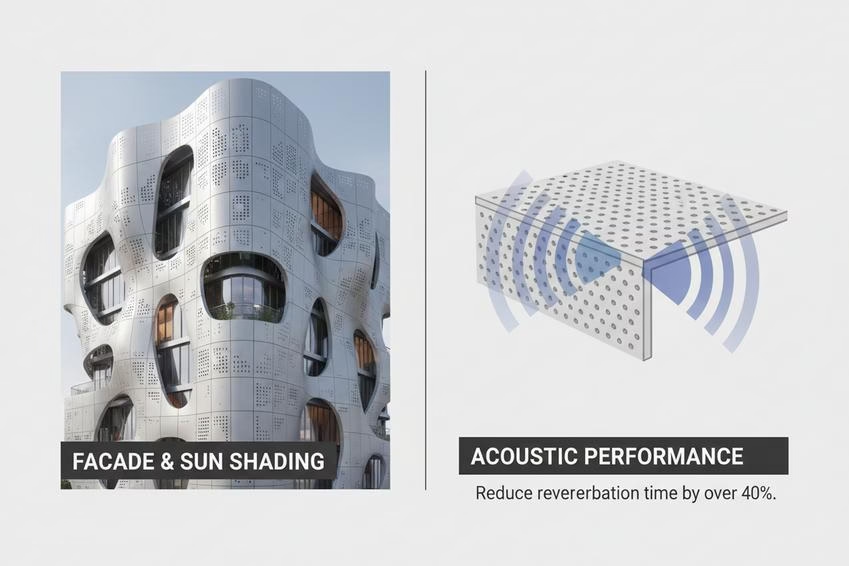

Facade Cladding and Sun Shading: Dual-Function Aesthetic Solutions

- Control light like a dimmer switch for your building.

- Keep interiors cooler by reducing solar heat gain.

- Give facades a facelift with artistic flair.

- Perforation patterns can be customized into hexagons, waves, or even abstract art—turning plain walls into creative canvases.

- These panels act as solar shading, cutting down glare while still letting in natural light.

- They also boost energy efficiency, helping reduce HVAC loads without sacrificing aesthetics.

☼ Designers love the way these panels play with sunlight—creating dynamic shadows that shift throughout the day.

The result? A visually rich surface where function meets beauty head-on through smart geometry and material choice.

Acoustic Performance with Optimized Open Area and Hole Size

• Ever walk into a room that just sounds “right”? That’s no accident—it’s acoustic science at work.

- The size of the perforations matters—a lot. Smaller holes absorb high-frequency noise better; larger holes tackle lower frequencies.

- The total open area percentage directly affects how much sound is absorbed versus reflected.

- Panel thickness adds another layer to the equation—thicker materials often improve low-end absorption.

Studies show that properly engineered acoustic performance using these panels can reduce reverberation time by over 40%, making them ideal for theaters, offices, and schools.

“Demand for high-performance architectural acoustics has surged 18% globally since 2023,” according to Archello Insights’ Q1 2024 report on sustainable interior solutions.

These aren’t just good-looking panels—they’re sonic problem solvers too.

Ventilation Grilles and Balustrade Infill—When Form Meets Function

Multiple short descriptive segments:

• Think airflow without ugly duct covers—that’s what custom perforated grilles deliver with style.

• Balcony safety doesn’t have to mean bulky rails; infills made from perforated sheets offer elegance plus compliance with modern codes.

• With CNC precision, you get consistent hole alignment every time—crucial for both air passage and visual rhythm.

Grouped multi-level nested sequence:

A) For ventilation grilles:

- Use lightweight material like aluminum alloy to minimize structural load.

- Apply surface treatment (like anodizing) for added durability against weathering.

- Opt for variable hole patterns based on airflow needs—from linear slots to honeycomb grids.

B) For balustrade infill:

- Balance openness with safety using calculated panel thickness.

- Ensure code compliance while maintaining design freedom through tailored perforation patterns.

- Add depth via finishes like matte black or brushed silver to enhance contrast against glass or concrete backdrops.

Together, these applications prove that when it comes to architecture, the little things—like hole size or pattern direction—can make a big impact on both looks and performance of your build-out using versatile aluminum panels.

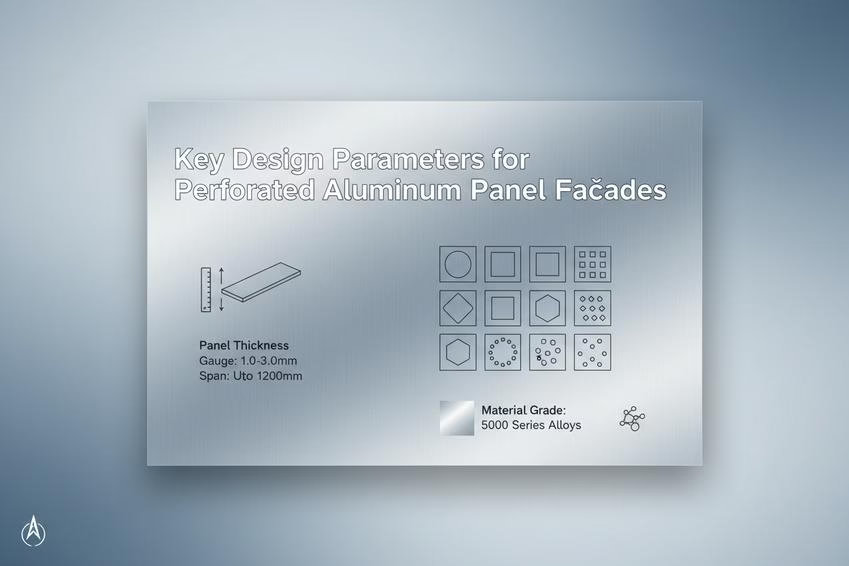

Key Design Parameters for Perforated Aluminum Panel Façades

Understanding how to spec out your panels right can make or break a façade project. Here’s what really counts.

Thickness, Gauge and Sheet Size—Finding the Balance Between Strength and Flexibility

Balancing strength with workability in perforated aluminum panels starts with three interlocked decisions:

A. Panel Thickness Selection

- Thin sheets (~1.5mm): Easier to bend, lighter load capacity

- Medium (~2.5mm): Ideal for façades needing moderate rigidity

- Thick (>3mm): Better for high-wind zones or large spans

B. Gauge Compatibility

- U.S. standard gauges often correspond differently across suppliers; always double-check conversion to mm

- Lower gauge = thicker metal = more weight but also more durability

C. Sheet Size Optimization

- Standard sizes like 1220×2440 mm are easier to source

- Oversized sheets may reduce seams but complicate transport or install

Each factor influences the others. Thicker panels allow larger sheet spans without sagging—but they’re heavier and harder to punch cleanly with intricate patterns.

Hole Shape, Pattern Type and Open Area Percentage Explained

Choosing the right hole layout in your aluminum perforated panels isn’t just about looks—it’s about airflow, light play, and even safety.

- ● Round holes offer timeless simplicity; square or hexagonal options add edge.

- ● Staggered patterns diffuse light better than straight rows.

- ● Open area above 40% enhances ventilation but weakens panel rigidity.

Want more drama? Go custom with oblong slots or asymmetric layouts—the higher the design ambition, though, the more you’ll need structural backing.

“Perforation geometry significantly impacts both visual transparency and wind resistance,” notes ARUP’s Building Envelope Report Q1/2024.

And don’t forget how pattern density alters shadow play throughout the day—it’s kinetic architecture at its finest.

Material Grade and Alloy Type—Ensuring Longevity and Corrosion Resistance

The type of aluminum alloy you pick shapes how long your panels last—and how much maintenance they’ll demand over time.

Group A – Common Alloys Used in Façade Panels

- 3003-H14: Great formability, decent corrosion resistance

- 5052-H32: High strength + superior resistance in coastal environments

- 6061-T6: Strongest option but harder to perforate cleanly

Group B – How Alloy Impacts Durability Factors

- Corrosion Resistance: Alloys with magnesium perform better near saltwater

- Weldability: Some alloys crack under thermal stress

- Surface Treatment Compatibility: Not all grades take anodizing evenly

If you’re working on a high-rise near the ocean—or even just a humid city—you’ll want an alloy that won’t pit or degrade fast under UV exposure or rain cycles.

Ensuring Precise Panel Dimensions Within Tolerance Limits

Precision is everything when it comes to aligning multiple perforated aluminum panel units across a wide façade grid.

I. Dimensional Accuracy Starts at Design Phase

A. CAD drawings must account for:

• Thermal expansion coefficients

• Punching shrinkage during manufacturing

B. Shop drawings should include:

• Edge tolerances (<±2mm)

• Hole center spacing accuracy

II. During Fabrication

A. CNC punching ensures repeatable accuracy

B. Laser cutting helps when tighter tolerances are needed around edges

Even tiny dimensional errors can throw off joint alignment across dozens of meters—so precision isn’t optional; it’s survival-grade essential for installers working at height.

Manufacturing Capabilities from Shearing to Fabrication

From raw coil stock to final install-ready units, turning metal into functional art takes serious machinery—and know-how.

1) Shearing defines initial dimensions before any decorative work begins.

2) CNC punching adds your chosen pattern—watch out for burrs on tighter curves.

3) Forming processes like press braking shape flanges or folds needed for mounting.

4) Finishing steps include deburring edges, applying coatings like PVDF or anodizing.

5) Final QA checks confirm hole alignment, flatness tolerance, surface finish consistency.

Each step can influence final cost per square meter—but skipping any one could compromise fitment on-site or visual quality after install.

So whether you’re speccing out a breezy sun screen wall or an acoustically tuned cladding system using custom-cut perforated aluminum sheets—you’ve got options… as long as you stick close to these key design rules!

Cost Control Strategies When Specifying Perforated Aluminum Panels

Keeping your project on budget without sacrificing quality starts with smart choices—especially when working with perforated aluminum panels.

Optimizing Material Grade and Thickness for Budget-Friendly Solutions

Choosing the right alloy and thickness of aluminum sheets can make or break your bottom line. Here’s how to keep costs low without cutting corners:

- Use mid-range aluminum grades like 3003-H14 or 5052-H32—they offer solid corrosion resistance and formability at a lower cost than premium alloys.

- Stick to an aluminum gauge between 12 and 16 for most architectural uses; it balances strength with material savings.

- Avoid overengineering—thicker doesn’t always mean better when your panel dimensions are modest.

- Standardize wherever possible. Custom thicknesses might sound cool, but they often blow up budgets fast.

When specifying perforated aluminum panels, tweaking just a few technical specs can save thousands without anyone even noticing.

Bulk Ordering Strategies—Maximizing Container Loading Efficiency

Bulk buying isn’t just about getting more—it’s about getting smarter with how much you order and how it’s packed:

- Calculate container capacity based on panel size, stacking height, and packaging volume.

- Align bulk orders with production cycles to reduce warehousing costs.

- Coordinate across multiple projects to fill containers efficiently—dead space is dead money.

- Choose standard sheet utilization formats that fit neatly into shipping containers.

Table: Example Container Load Optimization

| Panel Size (mm) | Panels per Stack | Stacks per Container | Total Panels |

|---|---|---|---|

| 1200 x 2400 | 50 | 20 | 1000 |

| 1000 x 2000 | 60 | 18 | 1080 |

| Custom Size | Varies | Inefficient | ~700 |

Maximize every inch of that container—your freight invoice will thank you later.

Cutting Shipping Costs with Smart Packaging and Delivery Scheduling

Shipping gets pricey fast—but it doesn’t have to if you play it right from the start:

• Use modular crating systems tailored to your panel dimensions, reducing voids inside packaging.

• Schedule deliveries during off-peak freight times when carriers offer better rates.

• Combine shipments across job sites using shared logistics platforms—it’s like carpooling for metal sheets!

Also, consider pre-labeling packages by install zone or floor level; this cuts time on site and reduces handling mistakes that cause damage.

When you’re dealing with perforated aluminum panels, smarter shipping beats faster shipping almost every time.

Striking the Right Balance Between ISO Certification and Expenses

ISO-certified materials? Nice flex—but do you really need them for every spec?

Multi-tiered approach works best here:

Tier A – Critical Visual & Structural Applications

- Go full ISO-certified sourcing

- Ensure compliance with quality standards

- Include documentation audits in supplier contracts

Tier B – Non-critical Back-of-House Installations

- Use suppliers who follow ISO-like practices but skip formal certification

- Focus on proven performance history over paperwork

Tier C – Temporary or Decorative Installations

- Consider non-certified sources if cost pressure is high

- Confirm basic mechanical properties via third-party testing instead of full certs

This layered strategy keeps your project looking sharp while keeping costs grounded—and Wallnova helps clients navigate these trade-offs like pros every day.

FAQs about Perforated Aluminum Panels

1. What Makes Modern Perforated Aluminum Panels Stand Out in Architectural Design?

Their charm lies in precision and expression:

- Alloy types such as 3003 and 5052 provide corrosion resistance for decades of outdoor life.

- Flexible panel dimensions allow rhythmic continuity across curtain walls or ceiling systems.

- Pattern type—straight pitch or staggered pitch—affects both shadow movement and building ventilation.

These elements come together to define a façade that feels light yet resilient.

2. How Does Panel Thickness Influence Form and Strength on a Building’s Face?

| Thickness Range | Visual Effect | Wind Load Capacity |

|---|---|---|

| 1–2 mm (Thin gauge) | Subtle curvature, smooth lines | Moderate |

| 3–4 mm (Standard façade use) | Defined surface presence | Strong |

| Above 4 mm (Heavy-duty zones) | Deep structural texture | Very high |

Material grade selection ensures formability without risk of deformation during shearing, punching, or forming.

3. Which Surface Finishes Protect the Panels from Harsh Outdoor Conditions?

Each finish serves its own weather story:

- Anodizing: builds resistant oxide layers while enriching tone depth; ideal for coastal sites.

- Powder coating: offers color flexibility with UV endurance; common in sun shading panels.

- PVDF coating: long-lasting gloss retention when façades face salt air or acid rain exposure.

A well-chosen surface finish defines not only protection but also the emotional temperature of architecture itself.

4. How Are Perforation Details Like Hole Shape or Open Area Percentage Decided?

Decision rests on rhythm, airflow, and light balance:

① Circular holes → soft diffusion, suited for acoustic panels inside halls;

② Oblong forms → evoke motion across gallery corridors;

③ Custom geometry → adjusts open area percentage to control daylight while retaining privacy levels.

Designers coordinate these metrics with fabrication capabilities like precise punching tolerance limits under ISO certification standards.

5. Can One Type of Panel Fulfill Both Functional and Decorative Roles?

Absolutely—the same sheet can shade sunlight by day and breathe through ventilation grilles at night:

• Facade cladding requires calculated hole size alignment against wind load tests;

• Balustrade infill demands safe edge cutting within strict material certifications;

• Ceiling systems rely on uniform perforations to maintain acoustic harmony.

Such duality gives aluminum its poetic simplicity—utility meeting artistry.

6. What Logistics Considerations Improve Cost Efficiency During Bulk Orders?

Short description + bullet points bring order into supply flow:

- Optimize shipment through full-container loading with protective packaging methods minimizing scratches on mill finish surfaces.

- Arrange delivery schedules aligned with site readiness to cut demurrage costs.

- Maintain export documentation reflecting inspection procedures and quality control checks.

Timely planning turns industrial materials into architectural stories delivered right on time.