In the world of big builds and bold ideas, the Aluminum Curtain Wall isn’t just a fancy façade—it’s your building’s armor, its billboard, and its backbone rolled into one. These slick panels don’t flinch at hurricane winds or sulk in salty coastal air. They’re built like tanks but dressed like runway models—sleek, strong, and ready for their close-up.

You know what kills budgets faster than bad coffee? Maintenance. That’s why developers are eyeing marine-grade alloys like 5052—they age slower than fine wine and laugh in the face of rust. “What we’re seeing now is smarter sourcing,” says Kara Liu, Senior Design Engineer at Wallnova (2024 Q1 Materials Insight). “Teams want lasting value—not just something that looks good on day one.”

And while you might think installation’s a pain… it doesn’t have to be. With pre-engineered mounting systems and anchor kits that click together smoother than IKEA furniture (minus the mystery screws), labor headaches shrink fast—and so does your project timeline.

So buckle up—we’re about to walk through design specs that win bids, finishes that stun clients, and install tricks that’ll make your GC high-five you on site.

Quick Insights on Aluminum Curtain Wall Systems

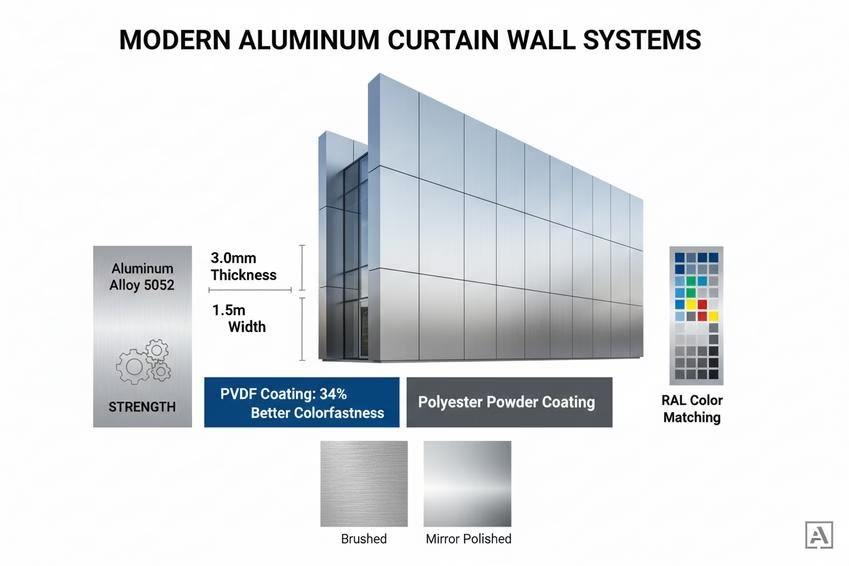

➔ Material Choice: Opt for Aluminum Alloy 5052 for superior corrosion resistance and longevity.

➔ Panel Dimensions: Standard thickness is 3.0mm with widths up to 1.5 meters, accommodating custom sizes.

➔ Coating Benefits: Choose PVDF or polyester powder coatings for durable, weather-resistant finishes.

➔ Color Customization: Utilize RAL color matching for precise design flexibility and aesthetic appeal.

➔ Surface Treatments: Decide between brushed textures for added depth or mirror polished surfaces for sleek elegance.

➔ Installation Efficiency: Follow panel guidelines and use appropriate anchoring hardware to minimize labor costs and ensure stability.

Understanding Aluminum Curtain Wall Systems: A Comprehensive Overview

Aluminum curtain wall systems bring together strength, sleekness, and design flexibility. Here’s what makes each part tick.

Material Selection: Why Choose Aluminum Alloy 5052?

Choosing the right material selection for your curtain wall setup isn’t just about looks—it’s about longevity and performance.

- Corrosion resistance: Aluminum alloy 5052 is practically immune to salt spray and industrial pollutants, making it perfect for coastal or urban builds.

- Strength-to-weight ratio: This alloy balances structural integrity with lightweight handling—ideal when you’re installing large aluminum panels at height.

- Formability: Whether you’re bending or welding, this material plays nice during fabrication without cracking under pressure.

- Sustainability: Fully recyclable and energy-efficient in production, it ticks the green box too.

- Thermal performance: While not naturally insulating, it’s compatible with thermal breaks to improve building envelope efficiency.

- Durability in harsh weather: It resists pitting and stress corrosion cracking better than many other aluminum grades.

Dimensions That Matter: Understanding Panel Sizes and Thickness

When you size up your next project, panel dimensions can make or break the flow—literally.

✓ Standard panel thickness hovers around 3.0mm, giving enough rigidity without going overboard on weight.

✓ Widths typically max out at 1.5 meters, while heights stretch as far as 4 meters, offering lots of room for customization without sacrificing structural balance.

But here’s where it gets interesting:

• Customization is king—fabricators often tailor panel shapes to sync perfectly with unique facade designs.

• Larger panels reduce joint lines but demand stronger support frames; smaller ones offer more flexibility but increase installation time.

That sweet spot? It’s all about balancing aesthetics with practicality in your final build.

Coating Options: Advantages of PVDF and Polyester Powder Coating

Not all coatings are created equal—and when it comes to finishing your aluminum curtain wall system right, these two dominate for good reason.

🟢 PVDF coating shines in UV resistance and long-term color retention—perfect for exteriors exposed to brutal sun cycles year-round.

🟣 Polyester powder coating, on the flip side, offers vibrant finishes at lower cost points while still holding its own against wear-and-tear indoors or in shaded zones.

Grouped Benefits:

• Weatherproofing Power – Both coatings shield against moisture intrusion and oxidation damage on the base metal surface.

• Aesthetic Range – Available across a wide palette; both support RAL color matching standards seamlessly.

• Maintenance Ease – Surfaces stay cleaner longer thanks to non-stick properties; occasional rinsing does the trick.

According to a 2024 report by BCI Global Construction Trends, “PVDF-coated aluminum curtain walls outperform others by up to 34% in colorfastness over ten years.”

The Color Factor: Exploring RAL Color Matching for Your Project

Color isn’t just visual—it’s emotional architecture wrapped into pigment precision. With RAL color matching baked into most modern fabrication workflows, designers can lock down exact hues that align with brand identity or architectural intent.

This system ensures that whether you’re ordering panels today or five months from now, the shade stays consistent across batches—even if produced continents apart. For public-facing buildings like malls or airports where consistency is key across massive surfaces, this matters big time.

RAL also allows architects greater freedom when blending elements like glass tints or signage colors into one cohesive look—no more guessing games between suppliers and finishers on what “charcoal grey” really means.

Surface Treatments: Choosing Between Brushed and Mirror Polished Aluminum

1️⃣ Brushed aluminum gives off an industrial vibe that’s subtle yet sophisticated—it hides fingerprints well too!

2️⃣ Mirror polished finishes, however, scream modern luxury; they reflect surroundings like glass but with metallic depth underneath the shine.

3️⃣ Each has its place: • Use brushed textures where tactile warmth is needed—think boutique hotels or cultural centers. • Go mirror-polished when you want drama—corporate HQs love that bold reflection game!

Both finishes enhance different styles of aluminum curtain wall setups depending on mood boards and material palettes chosen by architects early on.

| Finish Type | Reflectivity | Fingerprint Resistance | Common Use Case |

|---|---|---|---|

| Brushed | Low | High | Museums, libraries |

| Mirror Polished | High | Low | Skyscrapers, showrooms |

One thing’s certain—the finish you pick says just as much about your space as its shape does.

Benefits of Using Aluminum Curtain Walls in Modern Architecture

Aluminum curtain walls bring together performance, beauty, and sustainability—three things every modern building seriously needs.

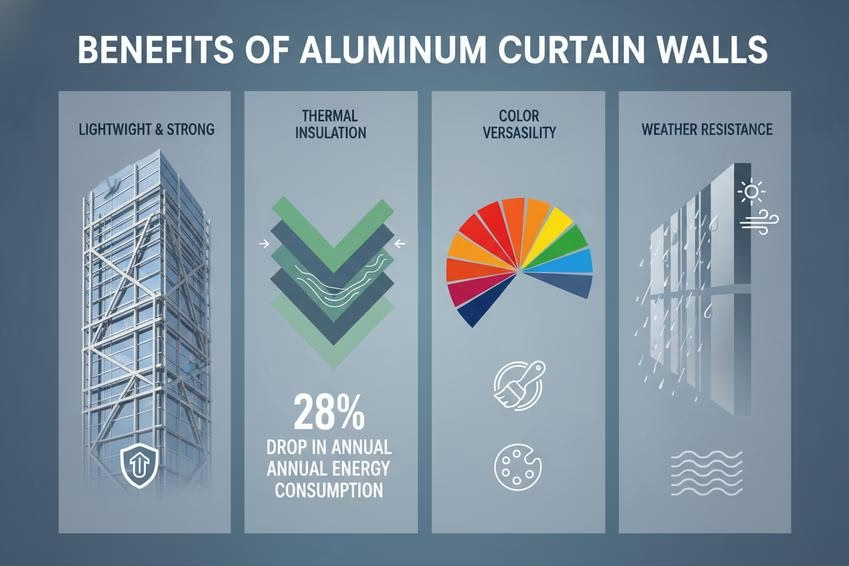

Lightweight Yet Strong: Benefits of Marine Grade Aluminum

- Marine grade aluminum is no joke when it comes to strength—it’s got the brawn without the bulk.

- Perfect for high-rises that need tough yet light exterior systems.

- The high strength-to-weight ratio makes installation faster and safer.

- It resists corrosion like a champ, especially near coastal areas where salt air wreaks havoc on other materials.

- Its long-term structural integrity helps reduce repair costs over time.

- Architects love how it supports large glass spans without adding stress to the frame.

- Bonus: It’s recyclable, which adds eco-points during LEED certification.

Energy Efficiency: The Role of Insulated Aluminum Panels

Insulated panels aren’t just filler—they’re your secret weapon against energy bills.

- These panels feature built-in thermal breaks, which block heat transfer like a pro.

- Lower U-values mean better insulation and reduced HVAC usage year-round.

- With smart design integration, they enhance the whole building envelope, keeping indoor temps comfy regardless of season.

- They’re lightweight too, so they don’t weigh down your structural load plan.

- According to the Global Building Performance Report 2024, buildings using advanced insulated aluminum panels saw up to a 28% drop in annual energy consumption.

Aesthetic Appeal: Custom Color Options for Design Flexibility

Color’s not just about looks—it’s about identity.

• Want subtle matte tones or bold metallics? Thanks to advanced powder coating, you can get either—or both.

• Need something more durable? Go with anodizing, which locks in color while boosting surface hardness.

• Designers can match nearly any shade with precision-level color matching tools available today.

Short version? You’re not stuck with silver or grey anymore—your facade can finally match your vision board.

Longevity and Maintenance: Weather Resistant Coatings Make a Difference

Let’s talk about staying power—because nobody wants to repaint every few years.

→ Step one: Choose coatings like PVDF or other top-tier fluoropolymer coatings that laugh in the face of UV rays and acid rain.

→ Step two: Apply them uniformly across all aluminum surfaces to ensure consistent protection and shine over decades—not just years.

These finishes are game changers when it comes to reducing upkeep costs while preserving visual appeal through all weather conditions.

And here’s the kicker—when paired with high-quality fabrication like what Wallnova offers once in a while—you’ll barely need touch-ups even after years exposed to sun, wind, or snowstorms.

Installation Steps for Aluminum Curtain Wall Systems

From anchoring hardware to panel precision, installing an aluminum curtain wall system is all about syncing accuracy with speed. Let’s break it down.

Panel Installation Guidelines: Ensuring Precision with Custom Sizes

• Always verify measurements twice before placing custom panels into position—accuracy here saves hours later.

• Use laser levels and plumb lines to maintain precision alignment across vertical and horizontal gridlines.

• Pre-check tolerances in shop drawings against actual on-site dimensions—minor mismatches can cause major headaches.

• Apply high-performance glazing materials rated for UV and moisture resistance to prolong life span.

“Custom-sized curtain wall panels now account for over 42% of new commercial installations,” according to BCI Construction Report Q1 2024, highlighting the growing demand for adaptable facade solutions.

Short tip bursts:

- Don’t forget edge spacing!

- Keep sealant beads consistent.

- Avoid overtightening fasteners on pre-drilled panels.

Curtain Wall Mounting Systems: Essential Anchoring Hardware Requirements

Grouped essentials:

Anchors & Fasteners

- Heavy-duty stainless steel fasteners

- Adjustable expansion bolts

- Corrosion-resistant anchors compatible with substrate types

Brackets & Connectors

- Load-bearing aluminum alloy brackets

- Thermal break-compatible structural connections

Support Materials

- High-density rubber shims for accurate shimming

- UV-rated silicone-based sealants

Here’s a quick reference table comparing common anchoring setups:

| Mount Type | Max Load (kN) | Install Time (min) | Recommended Use Case |

|---|---|---|---|

| Embedded Bracket | 7.5 | 30 | Concrete frame buildings |

| Surface Bolt-On | 5.2 | 20 | Retrofit projects |

| Hybrid Clip Rail | 6.8 | 25 | Mid-rise commercial |

This setup ensures your mounting systems are ready to take on wind loads, seismic shifts, and thermal movement—all without cracking under pressure.

On-Site Installation Support: Minimizing Labor Costs During Assembly

Short bursts of advice:

– Bring in dedicated supervisors familiar with unitized systems—this reduces rework time drastically.

– Use mobile cranes or mast climbers where possible; manual hoisting eats up crew hours fast.

– Invest in digital layout tools that sync with BIM—layout errors cost more than software licenses.

Symbol-style tips: ★ Coordinate delivery schedules tightly; avoid idle time waiting for panels.

★ Train your installation team thoroughly on safety protocols—it pays off in both speed and insurance savings.

★ Keep daily logs via cloud-based apps; transparency improves productivity metrics by up to 18%.

According to Dodge Data & Analytics (2024), projects that integrate real-time site logistics planning cut average labor costs by nearly $9 per square foot compared to traditional install workflows—a huge win when scaling large curtain wall jobs.

And if you’re wondering whether expert guidance makes a difference? Just ask anyone who’s ever had to realign a full bay after misaligned embeds…

FAQs about Aluminum Curtain Wall

What Makes Aluminum Alloy 5052 the Preferred Choice for Modern Curtain Walls?

Aluminum alloy 5052 speaks to balance—strength with grace, durability with lightness. Its natural corrosion resistance keeps high-rise building facades elegant in coastal air or industrial haze.

- Material advantage: Marine grade aluminum and anodized aluminum sheets unite rigidity with flexibility.

- Panel size freedom: Panels reach 1.5 m width × 4.0 m height, maintaining shape even at scale.

- Coating harmony: PVDF coating systems deepen endurance, while anti-graffiti coating options protect lasting appearance on commercial building cladding.

How Do Custom Panel Dimensions Support Architectural Creativity?

Custom panel sizes turn design sketches into living surfaces that respond to both structure and sunlight.

| Dimension | Standard Specification | Adaptable Range |

|---|---|---|

| Thickness | 3.0 mm | Variable per structural demand |

| Width & Height | 1.5 m × 4.0 m | Tailored modular panel dimensions |

Such precision eases fitment during architectural renovation projects or new construction developments where alignment is absolute.

Why Choose PVDF Coating Over Polyester Powder Coating?

PVDF coatings breathe longer life into exteriors exposed to intense UV rays and city pollutants.

• Reflective pigment layers deliver color consistency standards across large façades using the RAL color matching system.

• Self-cleaning coating technology cuts maintenance cycles—a quiet hero for tall towers under constant sun and rain.

A touch of human comfort: owners watch their residential complex exteriors age elegantly rather than fade unevenly.

How Important Are Anchoring Hardware Requirements During Installation?

Anchoring defines confidence—every fastener tells a story of safety in motionless strength.

① Proper hardware supports extruded aluminum profiles through turbulent winds without distortion of smooth surface treatment panels.

② Clear panel installation guidelines combined with on-site installation support reduce labor costs while improving alignment accuracy in curtain wall mounting systems.`